a circle machine

A technology of circular knitting machines and circular molds, applied in forming tools, feeding devices, manufacturing tools, etc., can solve the problems of low efficiency and achieve the effects of convenient adjustment, high production efficiency and high applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

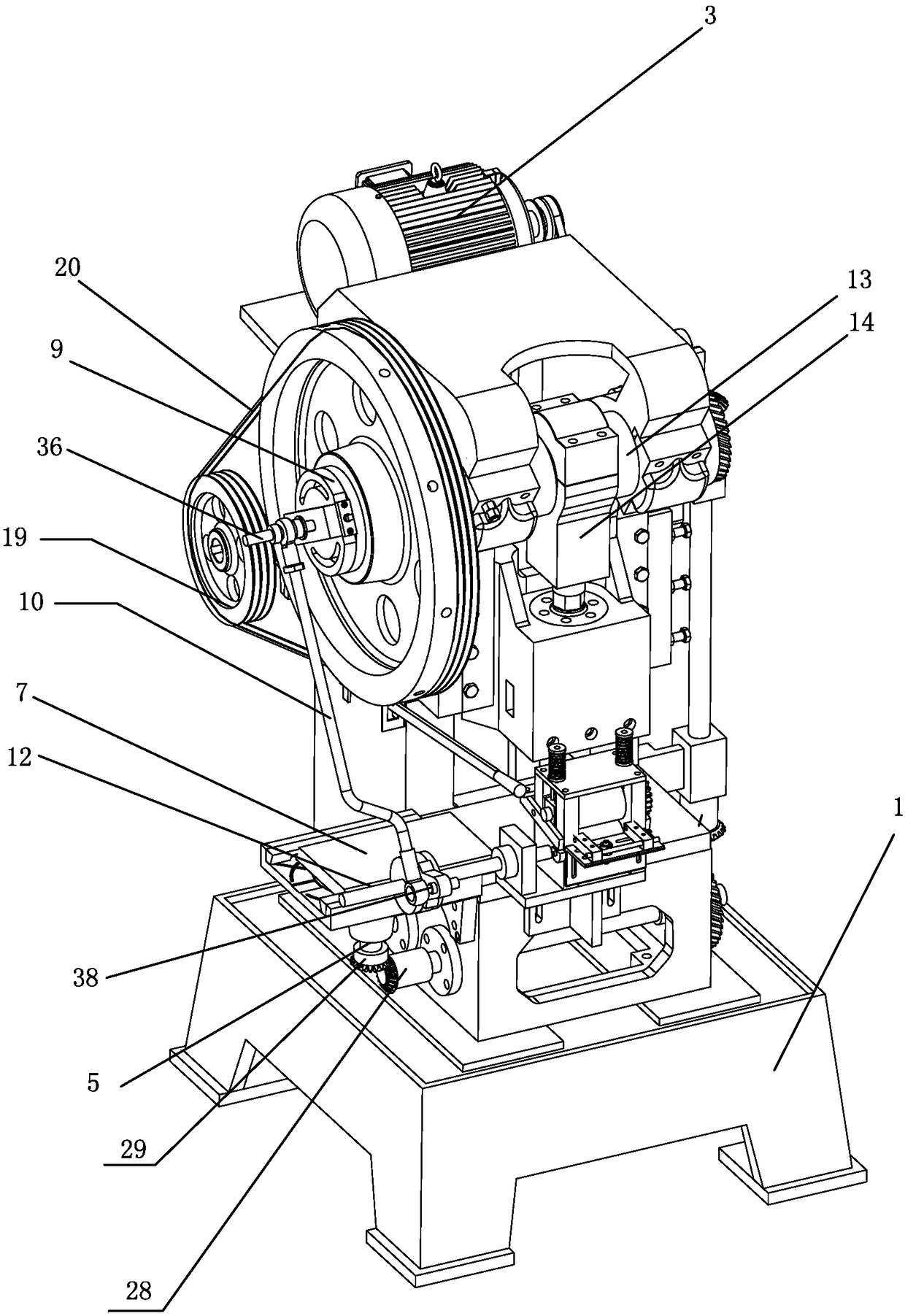

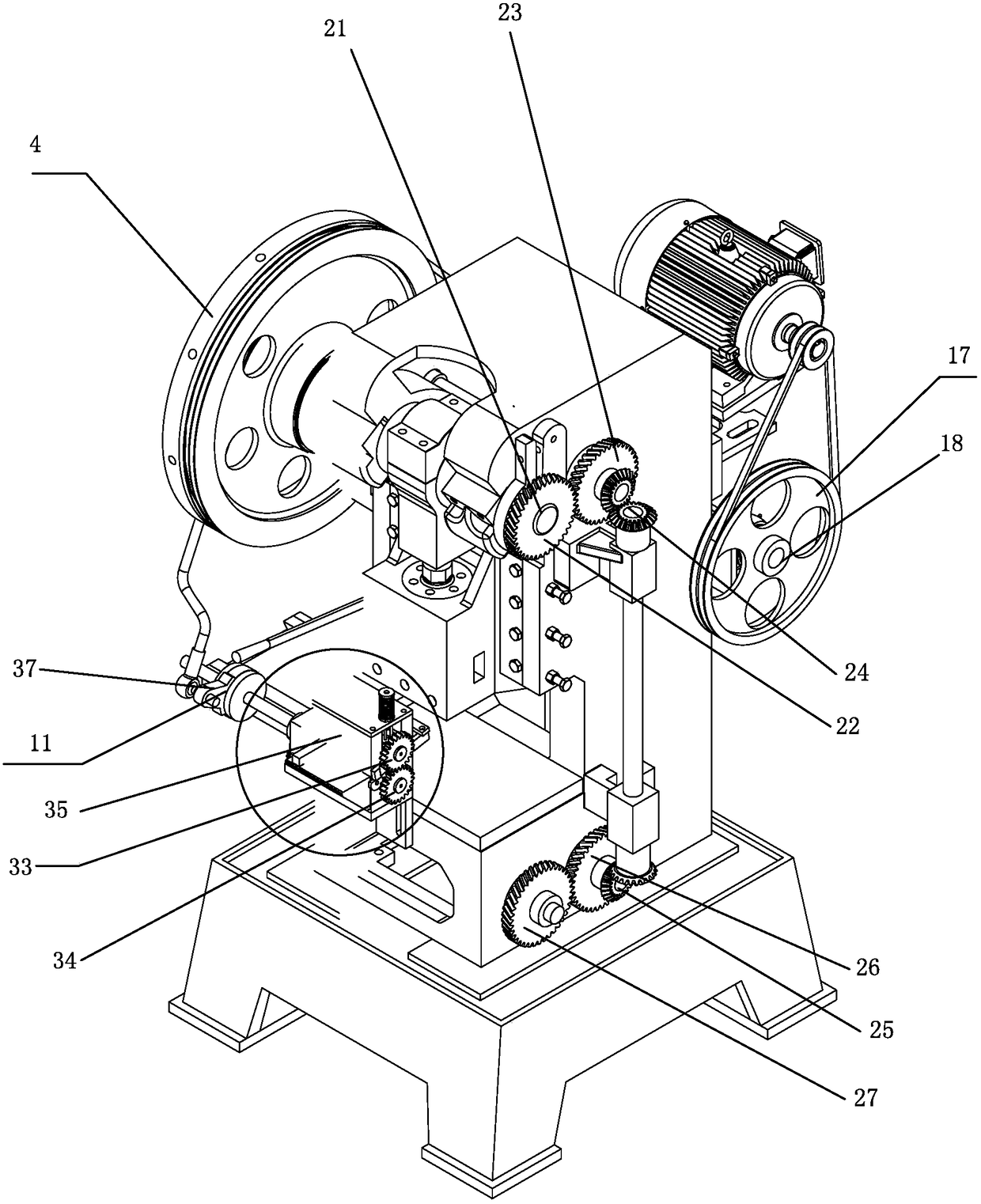

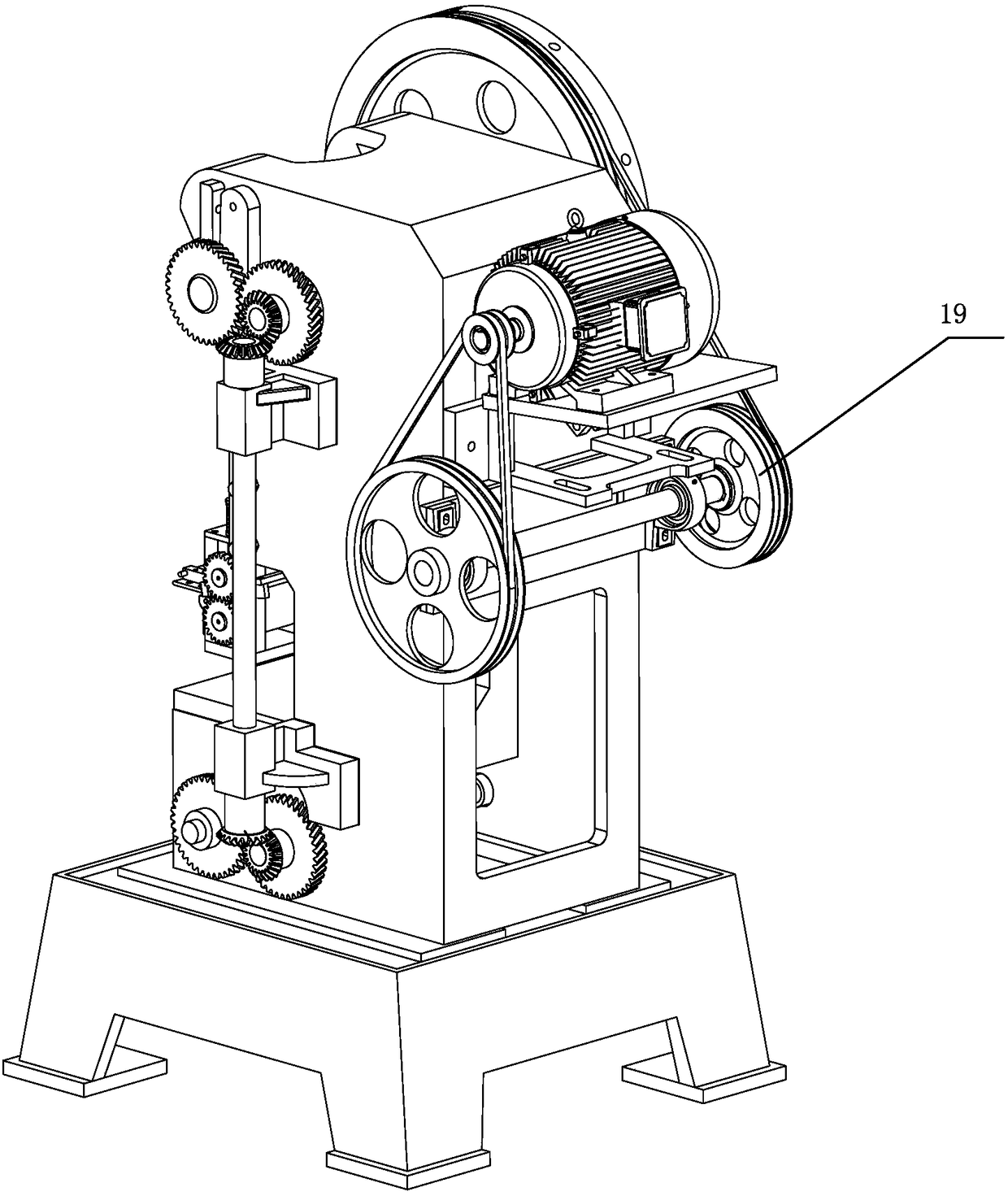

[0014] See attached Figure 1~5 Shown is a preferred embodiment of the circler machine according to the present invention. The rounding machine of the present invention is mainly used for cutting straight iron cores into circles. The circle machine includes a machine platform 1, a power mechanism installed on the machine platform, an intermittent feeding mechanism, an intermittent cutting mechanism, a horizontal pushing mechanism and a circular mold cavity 2. The power mechanism includes a motor 3, a flywheel 4 driven by the motor, and a gear transmission assembly driven by the flywheel 4. The gear transmission assembly has an output shaft 5, and the output shaft 5 is equipped with a motor that rotates with the output shaft 5. The eccentric wheel (not shown in the figure), the horizontal push mechanism includes a horizontal slider 7 horizontally arranged above the machine table 1 and pushed by the eccentric wheel to move horizontally reciprocatingly, and the fixed installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com