Structure for compositing wafers in inner caps

An internal compounding and wafer technology is applied in the field of the structure of inwardly covering the inner compounding wafer, which can solve the problems of low production efficiency and low operation efficiency of the production line, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

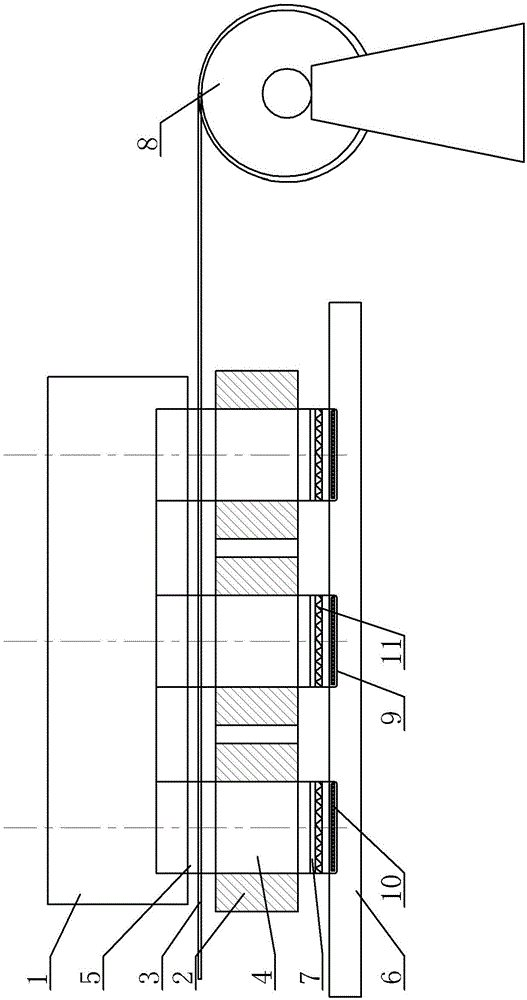

[0023] Embodiment 2: When the raw material structure 3 is a rectangular plate with a fixed size, each plate is transferred out of the bottom of the punching die as a whole after stamping is completed, and then replaced with a new plate.

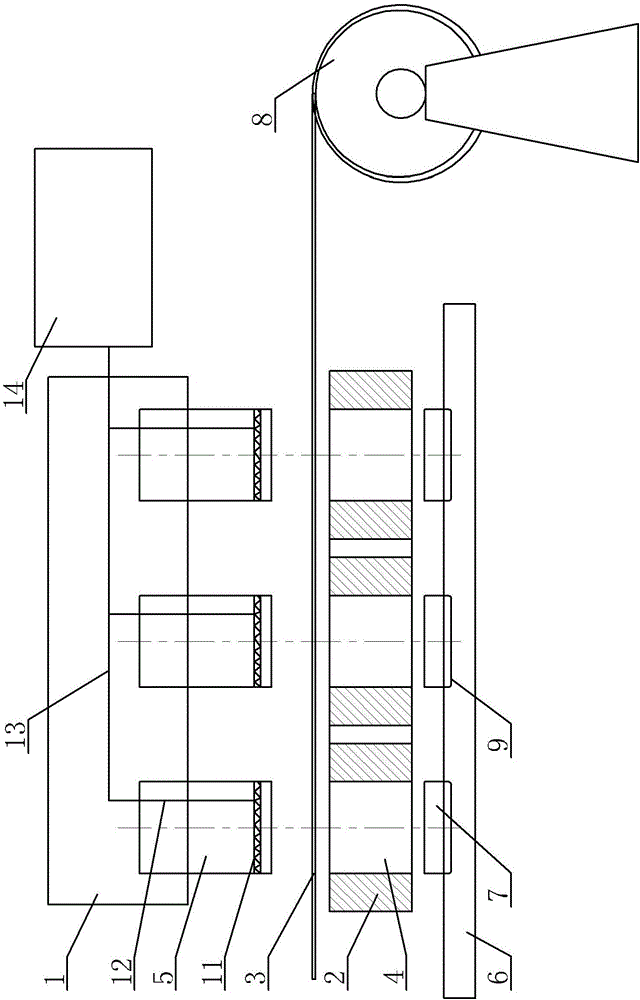

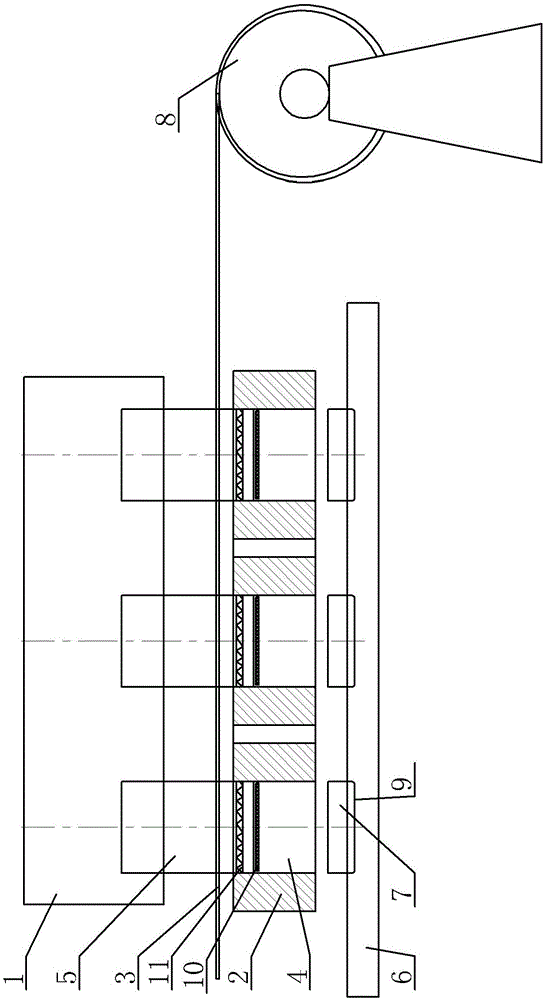

[0024] Its working principle is as follows: Lay the raw material structure on the plane of the lower punching die, lay the inner cover of the cover upwards on the cover laying platform, and set a cover directly below each lower knife edge to act as the upper knife edge After being heated to a suitable temperature by the heating coil, the upper knife edge is driven downward by the punch, and with the assistance of the lower knife edge, the raw material structure is punched to form a raw material sealing sheet, and then the upper knife edge continues to move downward until it is pressed The corresponding raw material sealing sheet is closely attached to the inner cover of the lid directly below. Since the temperature of the upper knife edge can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com