Application of an IR-doped titanium-based tin dioxide electrode with photoelectrocatalytic properties in the degradation of organic wastewater

A technology for obtaining titanium-based tin dioxide and photoelectric catalysis, which is applied in the directions of oxidized water/sewage treatment, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. The influence mechanism of electrode performance is not clear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Weigh chloroiridic acid and tin tetrachloride respectively according to the metal ion molar ratio of 1:15, dissolve them together in absolute ethanol, ultrasonically oscillate to dissolve them evenly, and then place them for 24 hours to obtain the coating solution;

[0021] 2) The industrial TA1 grade titanium plate was pre-degreased, sandblasted, etched with 20wt% boiling sulfuric acid for 40 min, and washed with water; then the coating solution obtained in step 1) was uniformly coated on the etched titanium substrate surface, and the coating amount Control the weight of iridium atoms per square centimeter on the titanium substrate to 0.4 mg, and then irradiate it with infrared light until it is solidified, then put it in a box-type resistance furnace at 500 ° C for 15 minutes, and then take it out of the furnace to cool;

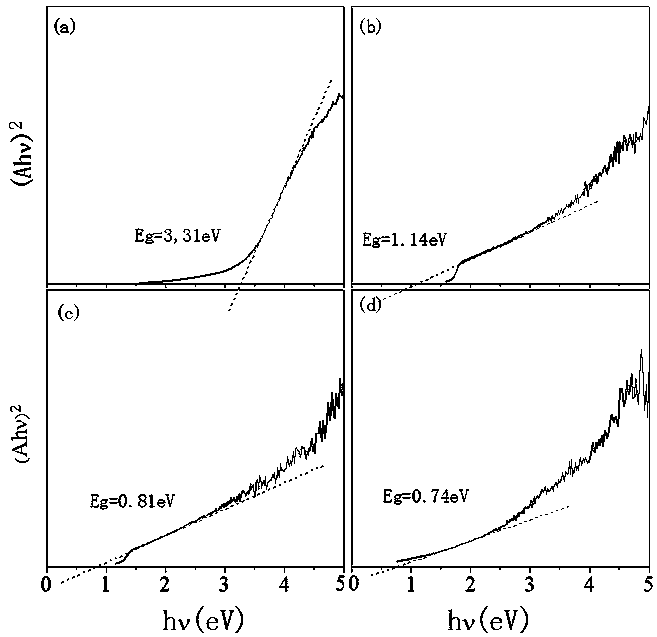

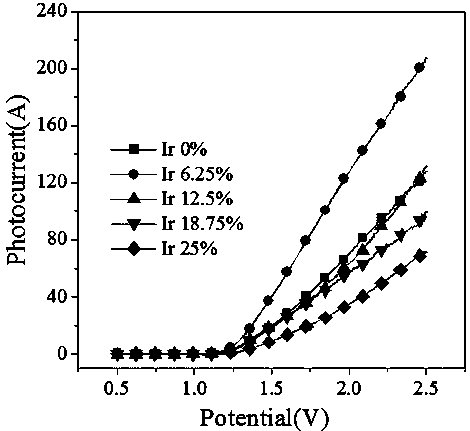

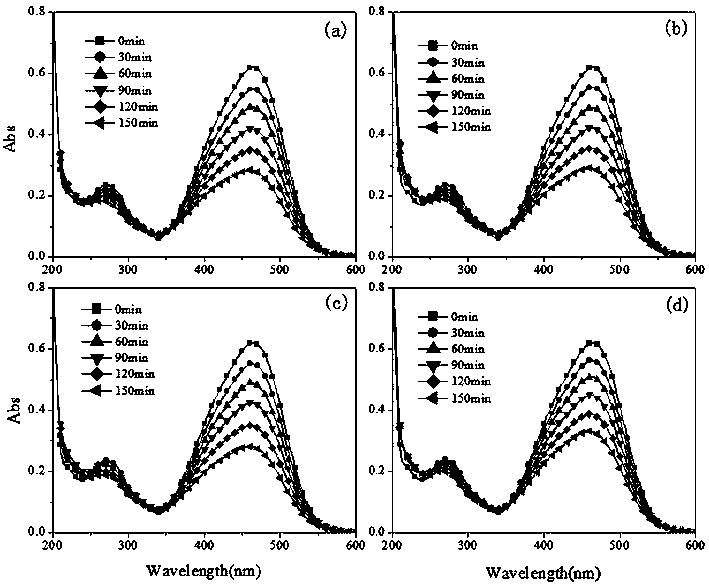

[0022] 3) After repeating the operation 3~5 times according to step 2), anneal at a constant temperature of 500°C for 60min to obtain 6.25mol% Ir...

Embodiment 2

[0024] 1) Weigh chloroiridic acid and tin tetrachloride respectively according to the metal ion molar ratio of 1:7, dissolve them together in absolute ethanol, ultrasonically oscillate to dissolve them evenly, and then place them for 24 hours to obtain the coating solution;

[0025] 2) The industrial TA1 grade titanium plate was pre-degreased, sandblasted, etched with 20wt% boiling sulfuric acid for 40 min, and washed with water; then the coating solution obtained in step 1) was uniformly coated on the etched titanium substrate surface, and the coating amount Control the weight of iridium atoms per square centimeter on the titanium substrate to 0.4 mg, and then irradiate it with infrared light until it is solidified, then put it in a box-type resistance furnace at 500 ° C for 15 minutes, and then take it out of the furnace to cool;

[0026] 3) Repeat step 2) for 3 to 5 times, then anneal at 500°C for 60 minutes to obtain 12.5mol% Ir-doped modified Ti / SnO 2 electrode.

Embodiment 3

[0028] 1) Weigh chloroiridic acid and tin tetrachloride respectively according to the metal ion molar ratio of 1:3, dissolve them together in absolute ethanol, ultrasonically oscillate to dissolve them evenly, and then place them for 24 hours to obtain the coating solution;

[0029] 2) The industrial TA1 grade titanium plate was pre-degreased, sandblasted, etched with 20wt% boiling sulfuric acid for 40 min, and washed with water; then the coating solution obtained in step 1) was uniformly coated on the etched titanium substrate surface, and the coating amount Control the weight of iridium atoms per square centimeter on the titanium substrate to 0.4 mg, and then irradiate it with infrared light until it is solidified, then put it in a box-type resistance furnace at 500 ° C for 15 minutes, and then take it out of the furnace to cool;

[0030] 3) Repeat step 2) for 3 to 5 times, then anneal at 500°C for 60 minutes to obtain 25mol% Ir-doped modified Ti / SnO 2 electrode.

[0031] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com