The workpiece output structure of the rectangular multi-leg stirrup welding device for shear walls

A technology for outputting structures and welding devices, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., which can solve the problems of cumbersome consumption and limited processing efficiency of rectangular multi-leg stirrups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

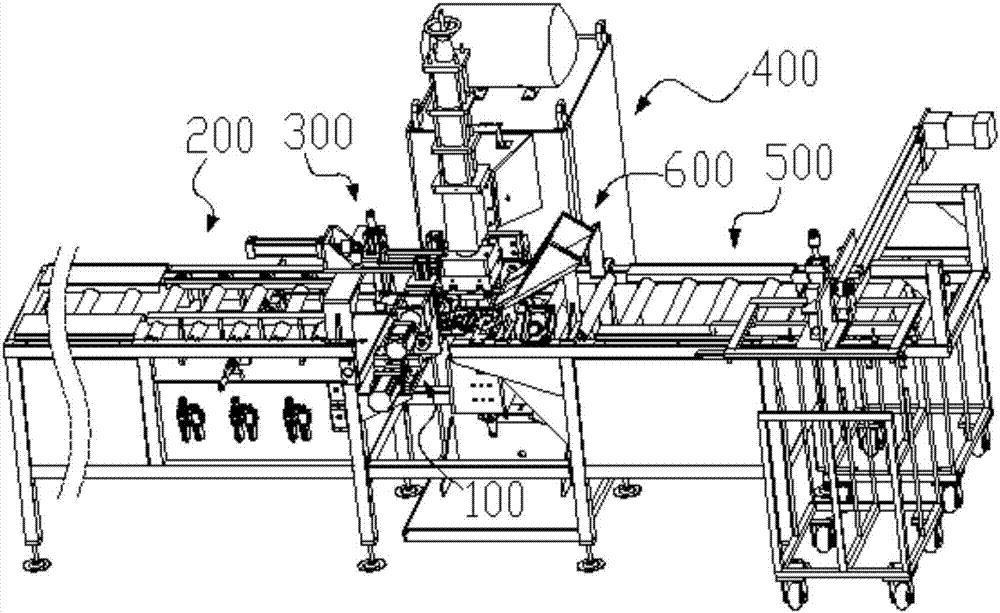

[0066] The present invention will be described in further detail below in conjunction with the accompanying drawings of a rectangular multi-leg stirrup welding device for a shear wall of the present invention. Wherein, the descriptive terms such as up, down, left, right, etc. are used for the description, with the purpose of helping readers to understand, but not intended to limit. In the following description, the side where the material input side is located is the front, and the side where the output side is located is the rear.

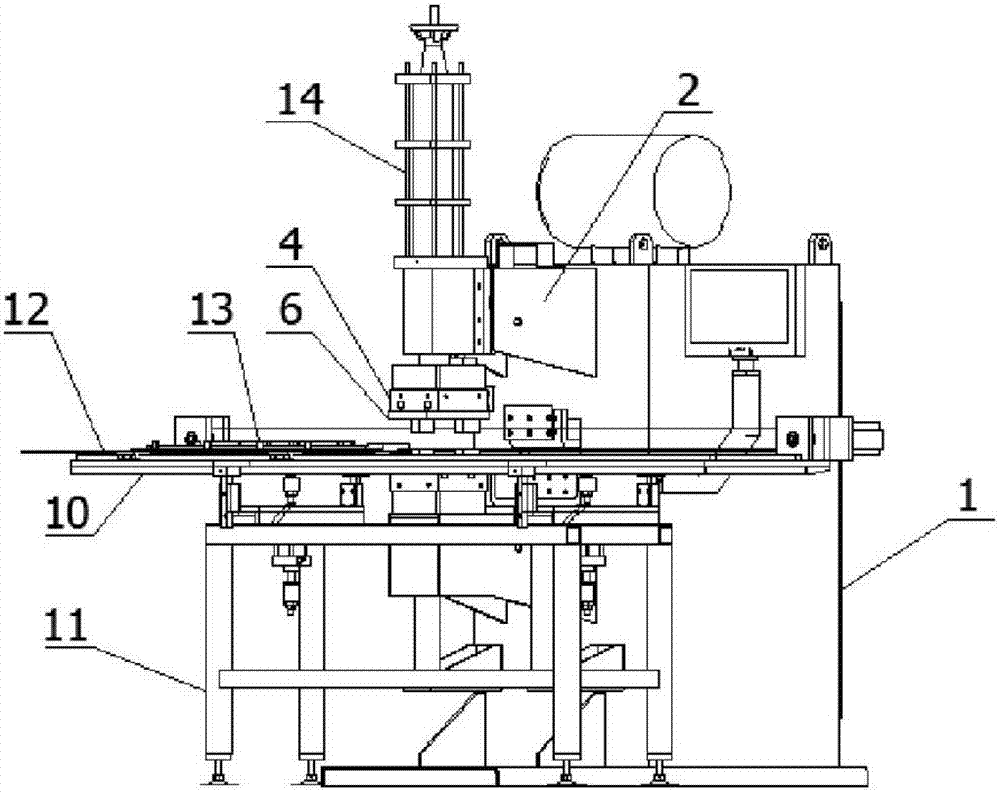

[0067] Rectangular multi-leg stirrup welding device for shear walls (such as image 3 As shown), including a welding machine 400, the welding machine 400 includes two sets of welding electrodes vertically opposite to each other, the lower set of the two sets of welding electrodes is a fixed set of lower welding electrodes, and the upper set of welding electrodes It is the upper welding electrode; the upper welding electrode is integrally installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com