Comprehensive electric welding operating vehicle

A working vehicle and operation technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as not easy to collect, endanger equipment and personnel safety, reduce work efficiency, etc., and achieve a standard electric welding operation site The effect of management, improvement of work efficiency and safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

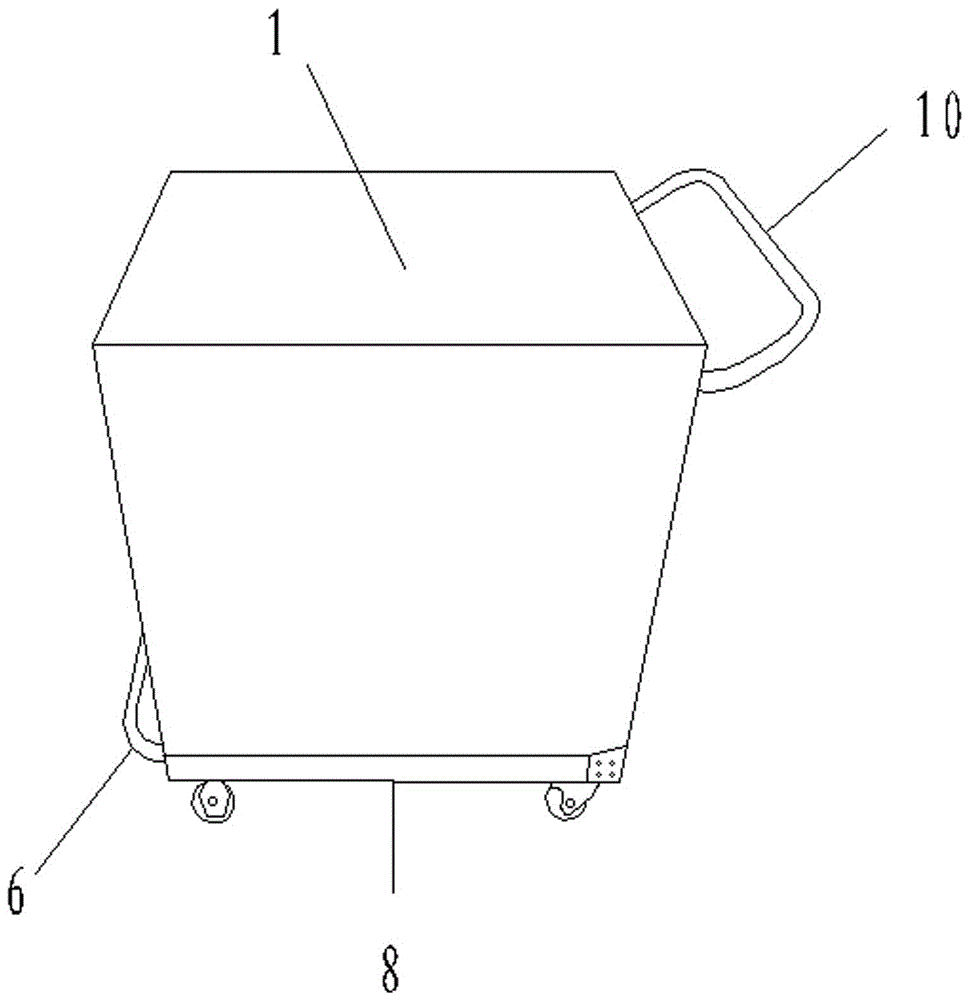

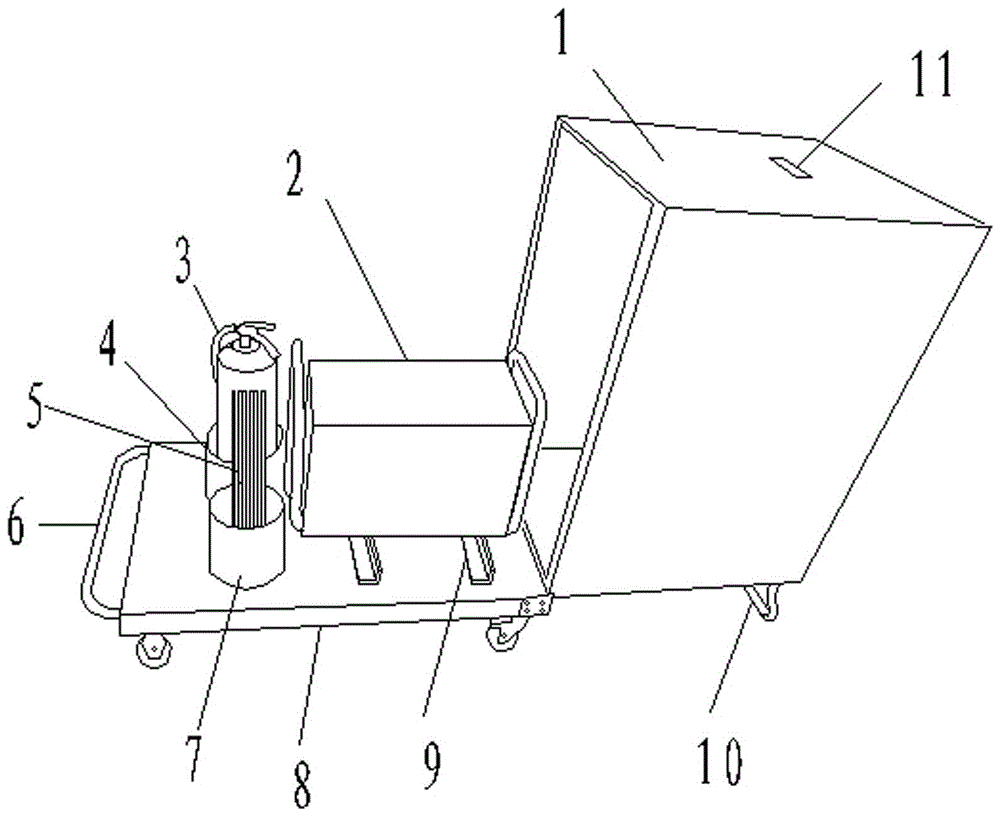

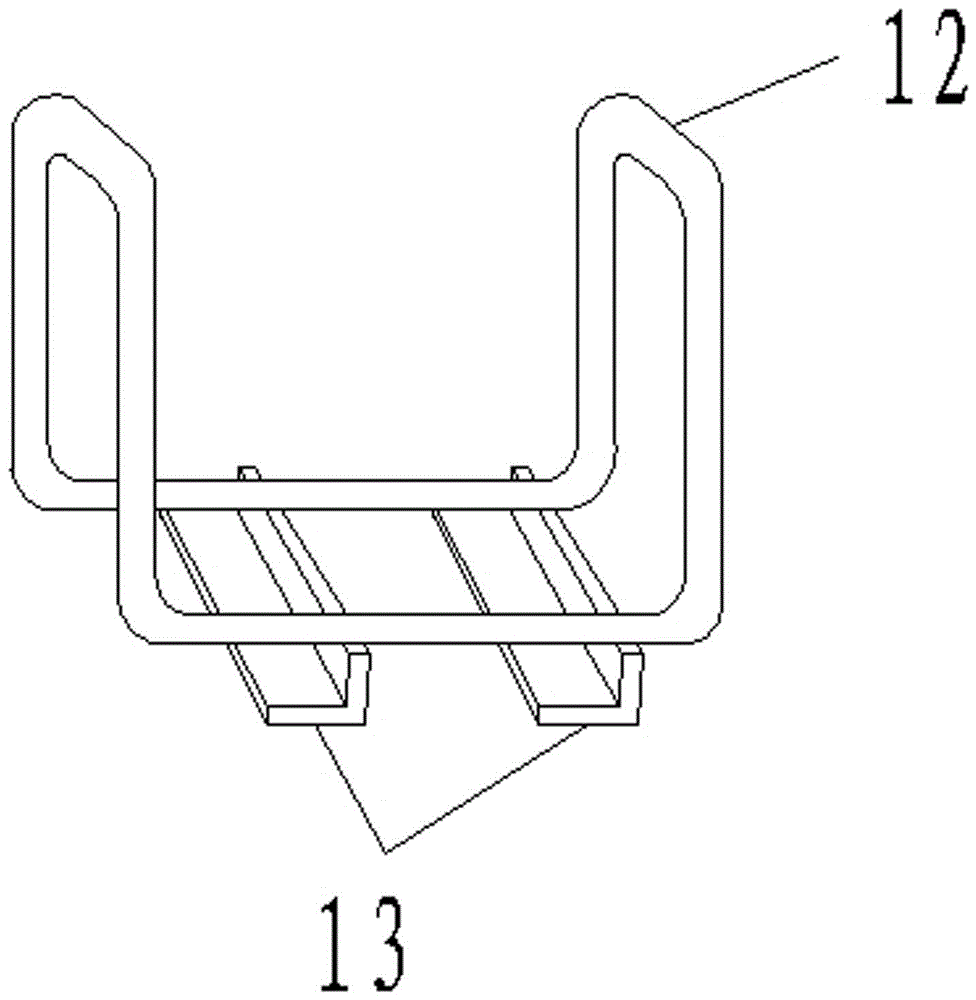

[0020] The present invention provides a figure 1 The electric welding comprehensive work vehicle shown includes a vehicle floor 8 and a vehicle shell 1, the vehicle floor 8 is used to place electric welding tools, the vehicle shell 1 can be covered on the vehicle floor 8, and the vehicle shell Body 1 is opened as figure 2 shown. Depend on figure 1 It can be seen that the items required for electric welding work are all concentrated in the enclosure of the car body 1, and its appearance is a closed box shape. Therefore, whether it is mobile work or storage in the management area, it is neat and orderly, conforming to Standard operation management also greatly reduces potential safety hazards. It should be explained here that the vehicle floor is provided with wheels, and the quantity of the wheels can be one, two, three or four, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com