Turntable type multi-station automatic welding feeding device

An automatic welding, multi-station technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as large error in manual handling position changes, differences in product welding accuracy, and continuous assembling and positioning of profiles, to enhance work stability. performance and reliability, improved welding stability, and the effect of improving work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

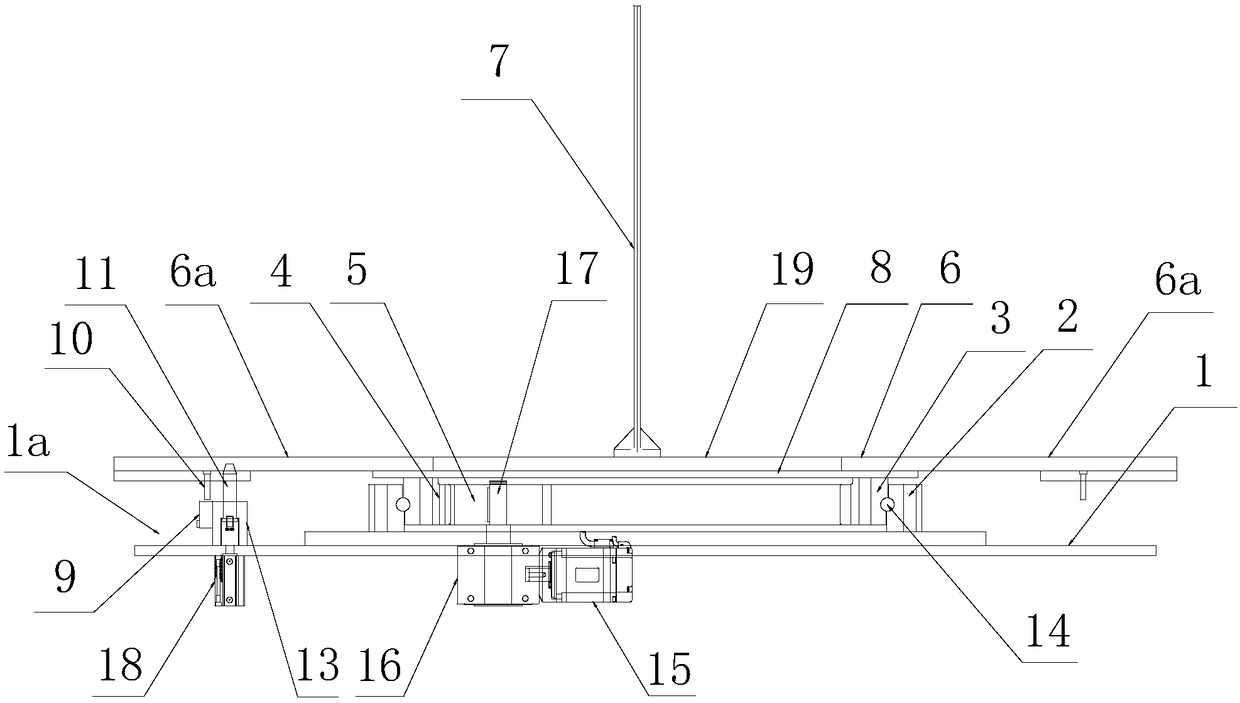

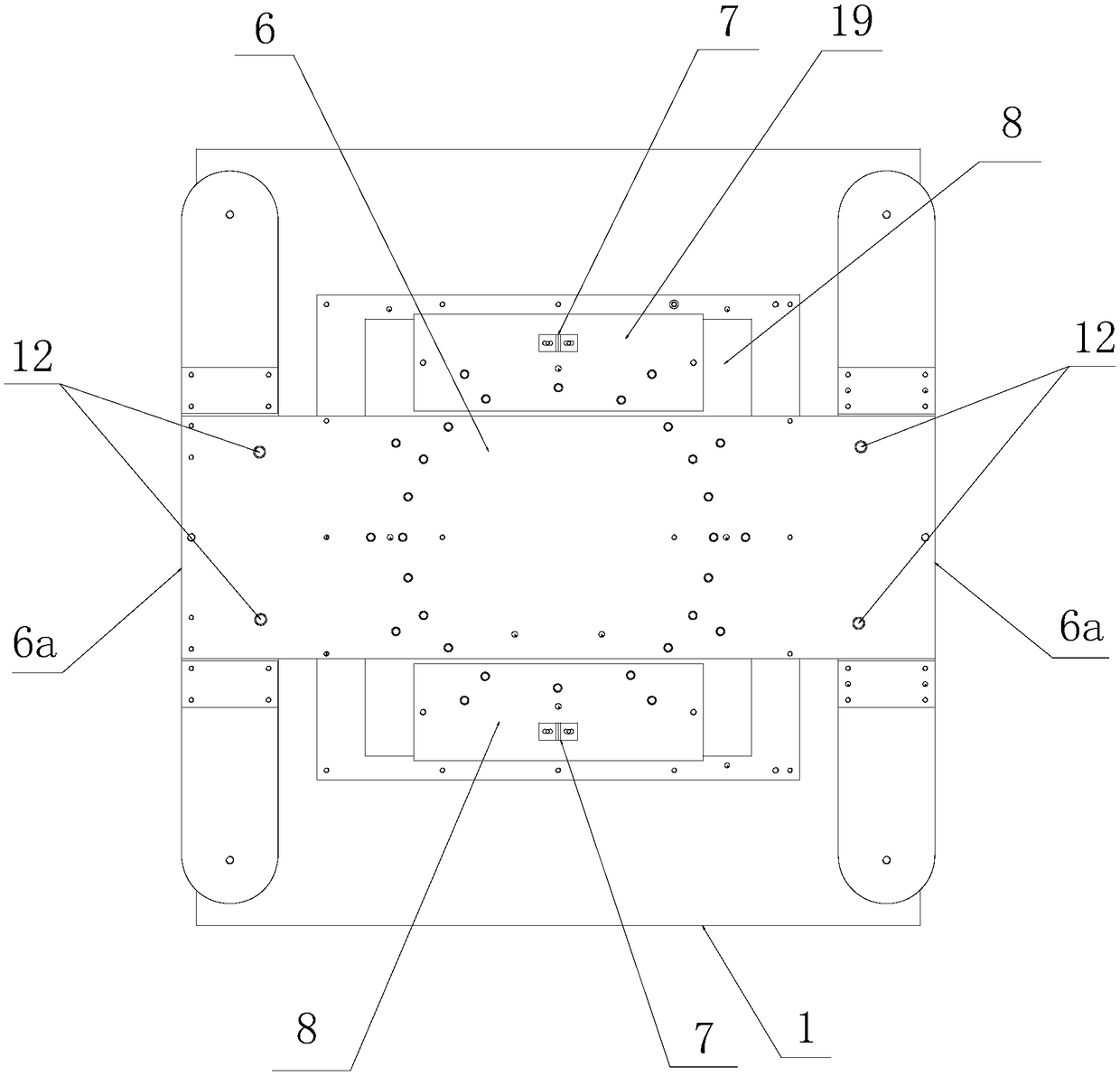

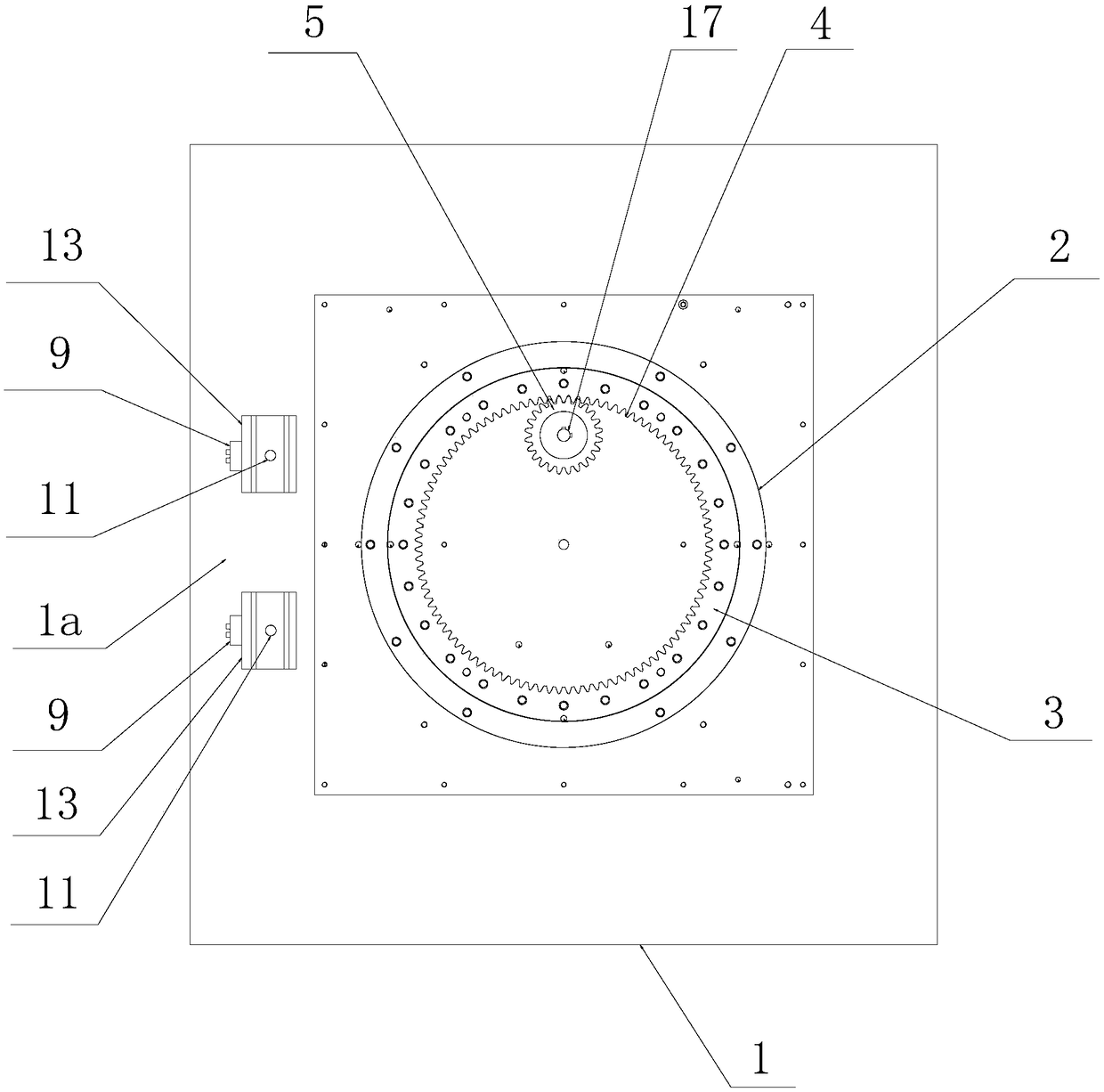

[0032] Example: Combine Figure 1~Figure 4 The specific implementation of the rotary table type multi-station automatic welding feeding device of the present invention is described as follows:

[0033] The device provided in this embodiment is mainly used for the welding and feeding of the outer metal support frame of kitchen and bathroom cleaning appliances. A connecting ring 3, the connecting ring 3 is integrally provided with an internal ring gear 4, the machine table 1 is provided with a gear 5 meshing with the internal ring gear 4, and the bottom of the machine table 1 is provided with a servo rotation drive for driving the gear 5 to rotate drive unit. And in this embodiment, a number of balls 14 (evenly spaced distribution) are embedded between the inner wall of the bearing ring 2 and the outer wall of the connecting ring 3 in the circumferential direction, and the inner wall of the bearing ring 2 and the outer wall of the connecting ring 3 are provided correspondingly....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com