A welding robot

A welding robot and welding head technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of operators being burned and the quality of welding products cannot be guaranteed, and achieve convenient operation, simple structure, The effect of high-efficiency and high-quality welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

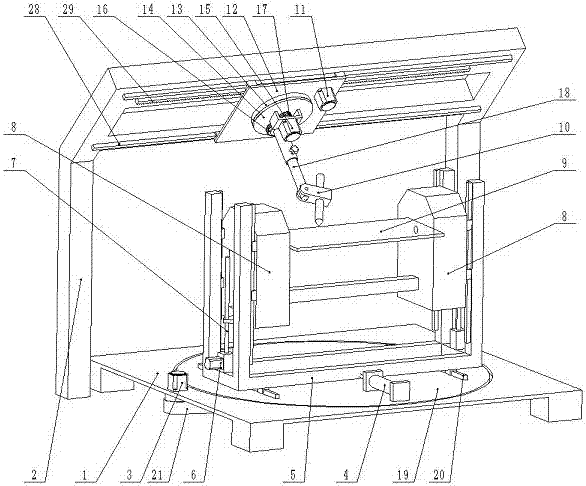

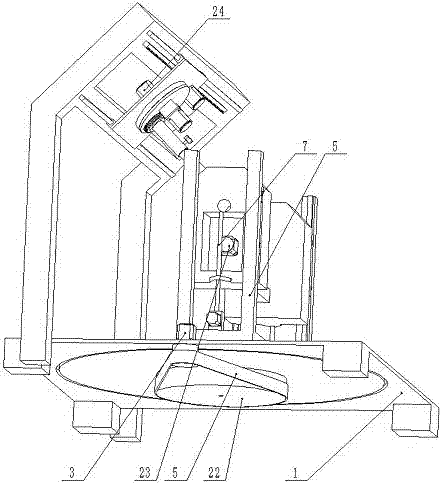

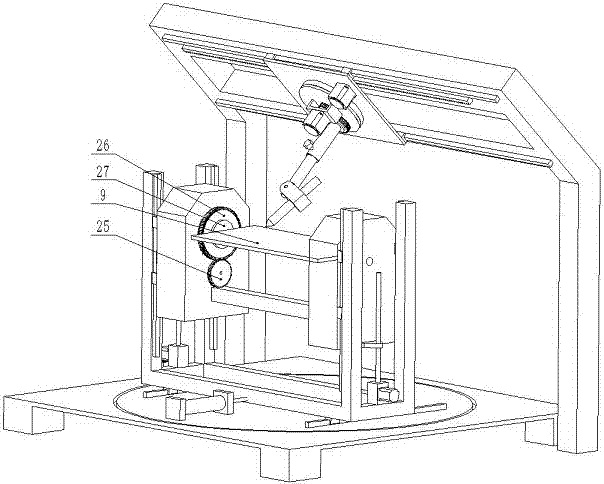

[0013] like figure 1 , figure 2 As shown, a welding robot includes a base 1 and a stand 2, a rotating disk 19 and a rotating motor 3, a rotating belt 21 and a large pulley 22, a workpiece mounting frame 5 and two workpiece mounting plates 8, a horizontal electric push rod 4, Two horizontal slide rails 20, two vertical motors 6 and two linear bearings 7, workpiece rotating motor 23, workpiece rotating master gear 25 and workpiece rotating slave gear 26, two welding slide rails 28 and welding moving rack 29, Welding mounting plate 12 and welding mounting plate 14, welding moving motor 11 and welding moving gear, welding ring gear 13, welding head rotating motor 15, welding head rotating main gear 17 and welding head...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap