Pre-tensioned prefabricated track board synchronous extension device and implementing method thereof

A track plate and pre-tensioning technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of inability to disassemble the device, transfer and reinstall, inability to achieve vertical and horizontal simultaneous tensioning, and uneven distribution of prestress, so as to shorten the production cycle , improve the efficiency of release, and achieve the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

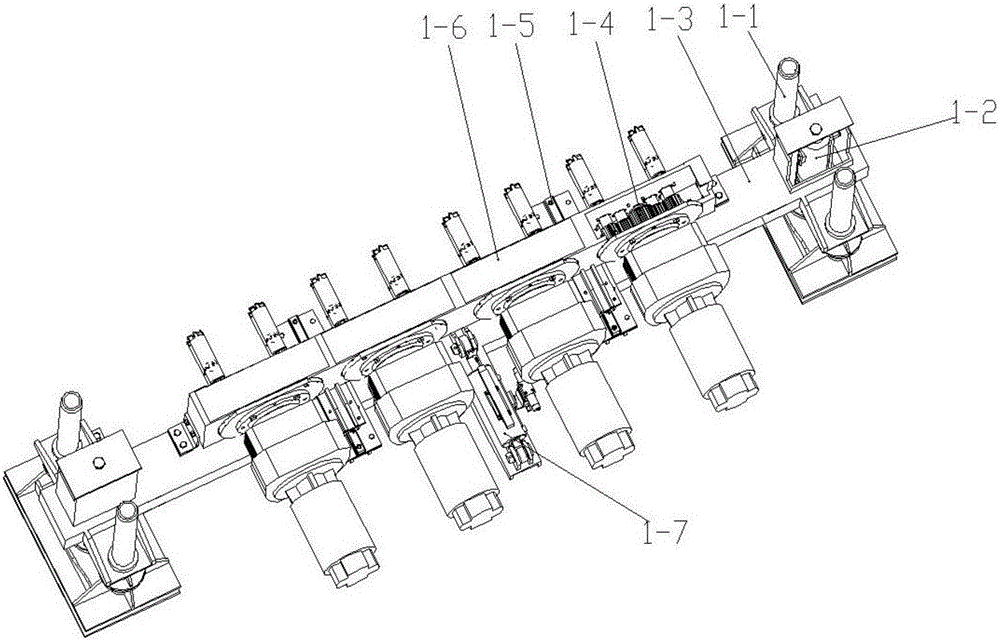

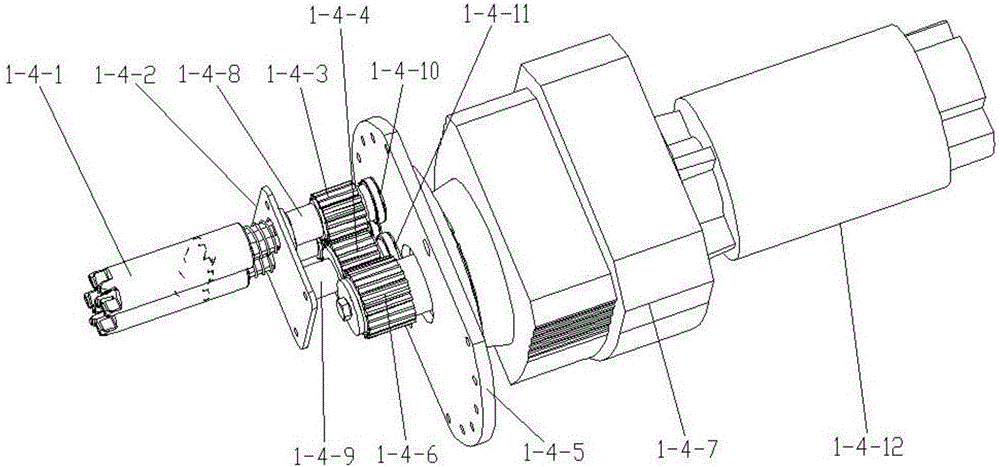

[0087] The present invention mainly realizes synchronous vertical and horizontal stretching by arranging a stretching mechanism on the end face and side of the track plate, and cooperating with the mold positioning device.

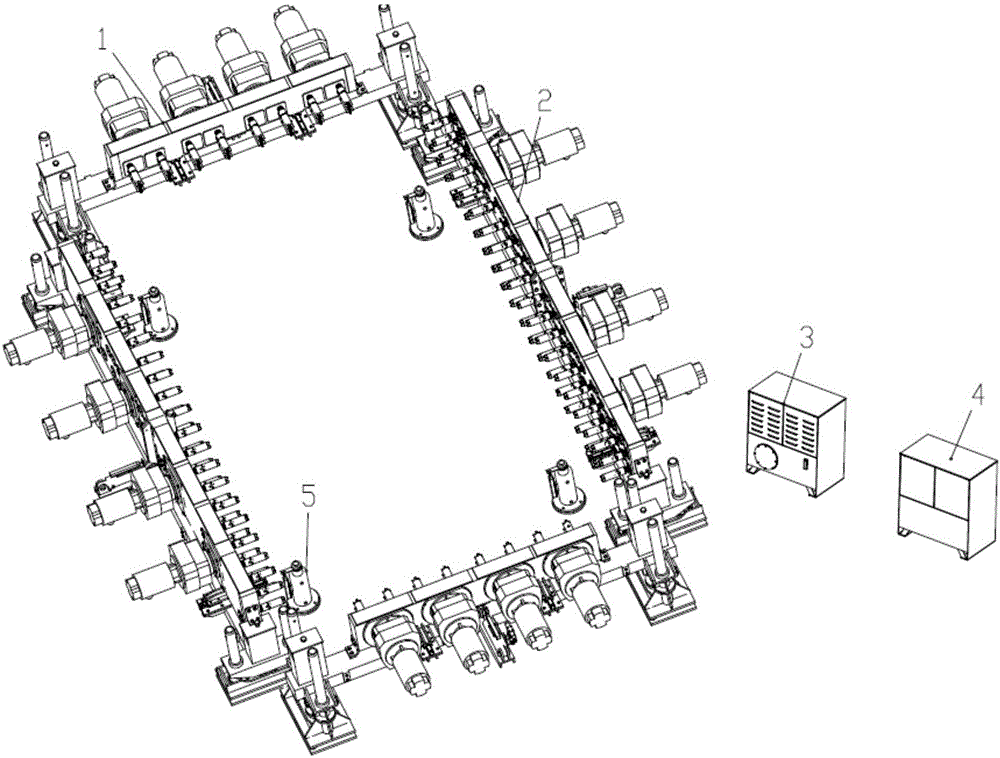

[0088] Specifically, the present invention provides a synchronous stretching device for pre-tensioned prefabricated track slabs, which includes:

[0089] The end stretching mechanism is installed on the working surface along the first installation direction, and has an end power unit for stretching. The end stretching mechanism has a first stretching direction for the end power unit to stretch, and is for adjustment The first adjustment direction for the end power unit;

[0090] The side stretching mechanism, which is installed on the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com