Skirt removal method, case processing method, case and electronic device

A skirt and thin-plate metal technology, applied in the field of casings and electronic devices, can solve the problem of inaccurate dimensions of finished metal casings, and achieve the effect of accurate dimensions and accurate height dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

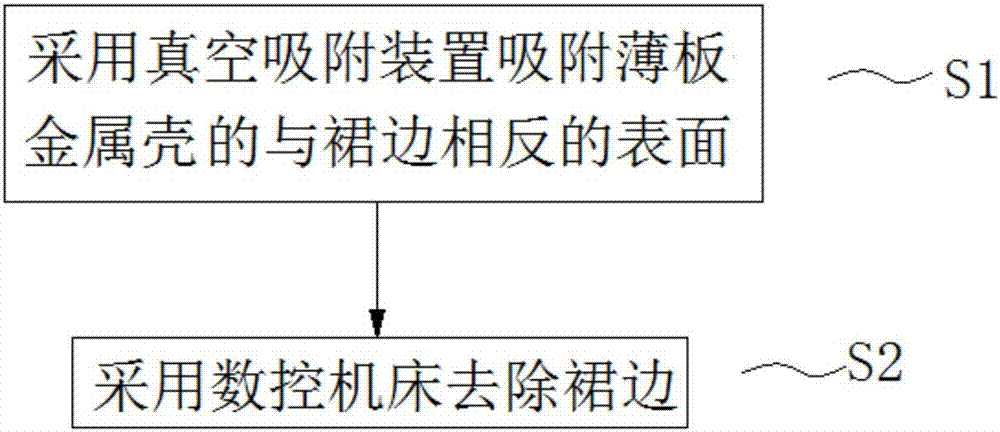

[0032] refer to figure 1 and figure 2 , the present embodiment provides a method for removing the skirt of a sheet metal shell. The method for removing the skirt of the sheet metal shell comprises the following steps:

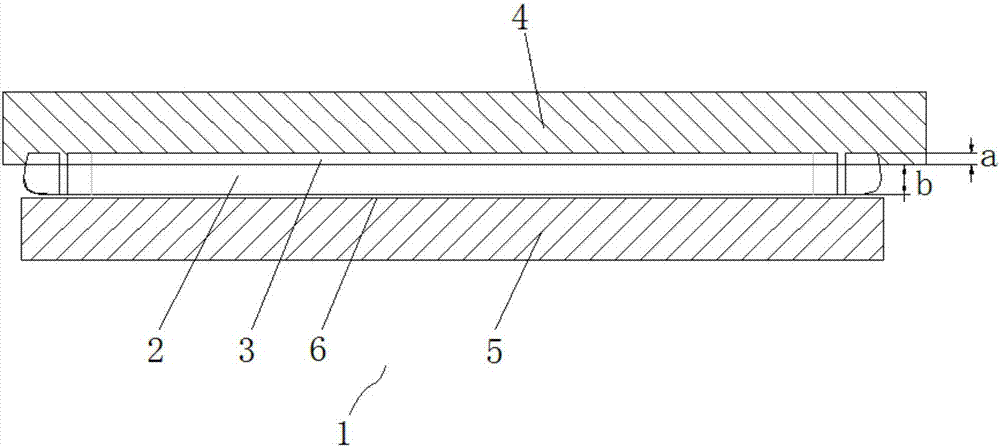

[0033] S1, using a vacuum adsorption device 1 to adsorb the surface of the thin-plate metal shell 2 opposite to the skirt 3;

[0034] S2. Using a CNC machine tool 4 to remove the skirt 3 .

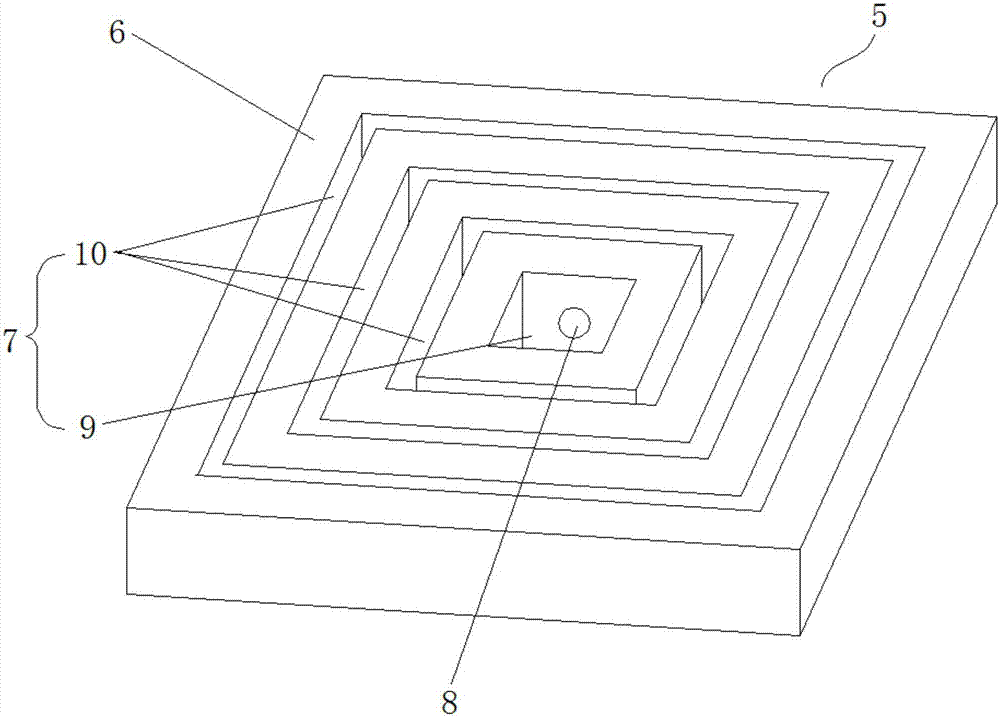

[0035] Thus, the thin-plate metal shell 2 is fixed by means of vacuum adsorption. For the thin-plate metal shell 2 with weak strength, the vacuum adsorption can absorb and smooth the entire surface opposite to the skirt 3, and take the smooth adsorption surface 6 as a reference. Processing the skirt 3 can ensure that the size of the sheet metal shell 2 is accurate.

[0036] Further, in this embodiment, the vacuum adsorption device 1 is located below the thin-plate metal shell 2 , the thin-plate metal shell 2 is the metal shell of the electronic device, and the metal sh...

Embodiment 2

[0048] refer to Figure 6 , In this embodiment, a casing processing method is provided. The shell processing method comprises the steps of:

[0049] Step 1, forming a thin-plate metal shell 2 by using a metal sheet, and the thin-plate metal shell 2 includes a skirt 3;

[0050] Step 2, performing in-mold injection molding on the thin-plate metal shell 2, forming a plastic part connected to the thin-plate metal shell 2;

[0051] Step 3: Remove the skirt 3 by using the method for removing the skirt of the sheet metal shell in Embodiment 1 to form a shell.

[0052] Of course, the shell formed in step 3 is not the final product. The shell formed in step 3 needs post-processing including oxidation, sandblasting, highlighting, and protective film to enhance the appearance and functionality of the metal shell. And during the processing, it can be polished, de-sharpened and cleaned at any time according to the needs.

[0053] Preferably, the casing is a casing of an electronic devi...

Embodiment 3

[0055] In this embodiment, a housing is provided, which is manufactured by the housing processing method in Embodiment 2, and has an accurate height dimension. Preferably, the casing is a casing of an electronic device, and the electronic device is an electronic mobile device such as a mobile phone, a tablet computer, a learning machine, a game machine, or the like. More preferably, the above casing is a mobile phone casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com