A kind of multi-layer structure reinforced composite car carpet

A technology for reinforcing composites and car carpets, applied in lamination, layered products, lamination devices, etc., can solve the problems of poor sound insulation effect, affecting the safety of passengers, and staying high, and achieves easy processing and excellent sound absorption Function, effect to prevent the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

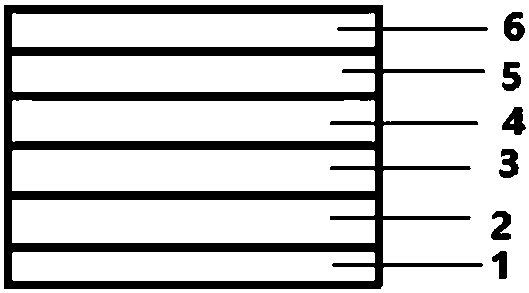

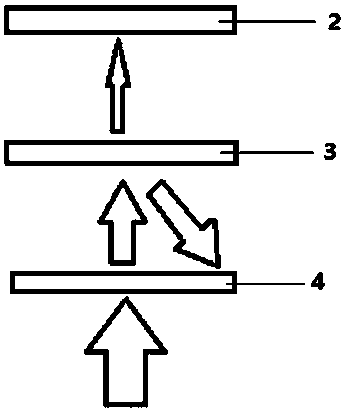

[0044] A multilayer structure reinforced composite automobile carpet, the multilayer structure reinforced composite automobile carpet includes a PET / PP composite layer (2); the PET / PP composite layer (2) includes PET with a weight ratio of 70 parts and 52 part of PP; the front of the PET / PP composite layer (2) is provided with an EVA sound-insulating layer (3); the thickness of the EVA sound-insulating layer (3) is 0.65 mm; the square gram of the EVA sound-insulating layer (3) Weight is 150 g / m 2 ; The front side of the EVA sound insulation layer (3) is provided with a PET needle-punched fabric layer (4); the PET needle-punched fabric layer (4) adopts fine denier PET fibers; the PET needle-punched fabric layer (4) includes The weight ratio is 74 parts of fine denier PET fiber and 12 parts of L-PET fiber; the square gram weight of the PET needle-punched fabric layer (4) is 450 g / m 2 .

[0045] Further, an anti-slip layer (1) is provided on the back of the PET / PP composite lay...

Embodiment 2

[0062] A multilayer structure reinforced composite automobile carpet, the multilayer structure reinforced composite automobile carpet includes a PET / PP composite layer (2); the PET / PP composite layer (2) includes PET with a weight ratio of 62 parts and 58 part of PP; the front of the PET / PP composite layer (2) is provided with an EVA sound-insulating layer (3); the thickness of the EVA sound-insulating layer (3) is 0.5 mm; the square gram of the EVA sound-insulating layer (3) weighs 125 g / m 2 ; The front side of the EVA sound insulation layer (3) is provided with a PET needle-punched fabric layer (4); the PET needle-punched fabric layer (4) adopts fine denier PET fibers; the PET needle-punched fabric layer (4) includes The weight ratio is 72 parts of fine denier PET fiber and 10 parts of L-PET fiber; the square gram weight of the PET needle-punched fabric layer (4) is 410 g / m 2 .

[0063] Further, the back of the PET / PP composite layer (2) is provided with an anti-slip layer...

Embodiment 3

[0080] A multilayer structure reinforced composite automobile carpet, the multilayer structure reinforced composite automobile carpet includes a PET / PP composite layer (2); the PET / PP composite layer (2) includes PET with a weight ratio of 78 parts and 42 parts of PP; the front of the PET / PP composite layer is provided with an EVA sound-insulating layer (3); the thickness of the EVA sound-insulating layer (3) is 0.8 mm; the square gram weight of the EVA sound-insulating layer (3) is 180 g / m 2 ; The front side of the EVA sound insulation layer (3) is provided with a PET needle-punched fabric layer (4); the PET needle-punched fabric layer (4) adopts fine denier PET fibers; the PET needle-punched fabric layer (4) includes The weight ratio is 80 parts of fine denier PET fiber and 15 parts of L-PET fiber; the square gram weight of the PET needle-punched fabric layer (4) is 500 g / m 2 .

[0081] Further, the back of the PET / PP composite layer is provided with an anti-slip layer (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com