Zeolite-like lightweight heat preservation and sound insulation board and production method thereof

A thermal insulation and sound insulation, zeolite-like technology, applied in the preparation of zeolite-type lightweight thermal insulation and sound-insulation panels, in the field of zeolite-type lightweight thermal insulation and sound-insulation panels, can solve problems such as environmental hazards, white pollution, and difficulty in processing and degradation, and achieve effective results Good, delayed coagulation time, strong sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

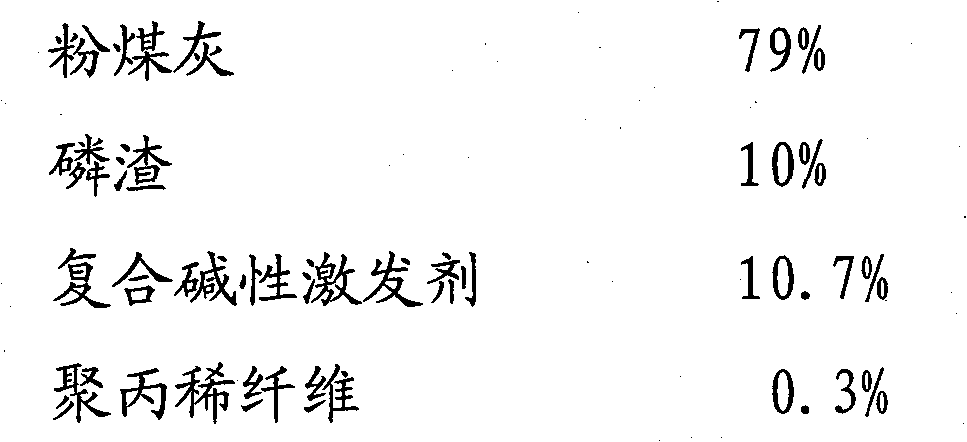

[0019] 1. Formula and preparation of dry powder slurry

[0020]

[0021] According to the above weight ratio, each component is stirred evenly to prepare a dry powder slurry, wherein the composite alkali activator is to add analytically pure NaOH solution to the industrial water glass solution with a modulus of 3.2, and adjust its modulus to 1.2. Na 2 O content is 9%;

[0022] 2. Preparation of light heat insulation and sound insulation board

[0023] Take 90 parts of the above-mentioned dry powder slurry and 10 parts of EPS granules, mix them well and press them into a mold for molding, demould after 1 day of molding, and maintain at 60°C for 3 days; the EPS granules are made by crushing waste EPS boards into a particle size of 3mm particles.

[0024] 3. Sheet performance

[0025] Bulk density is 500kg / m 3 , the 28d compressive strength is 7.6Mpa, the thermal conductivity is 0.083W / (m K), the average sound absorption coefficient in the low frequency band 200-2000Hz is...

Embodiment 2

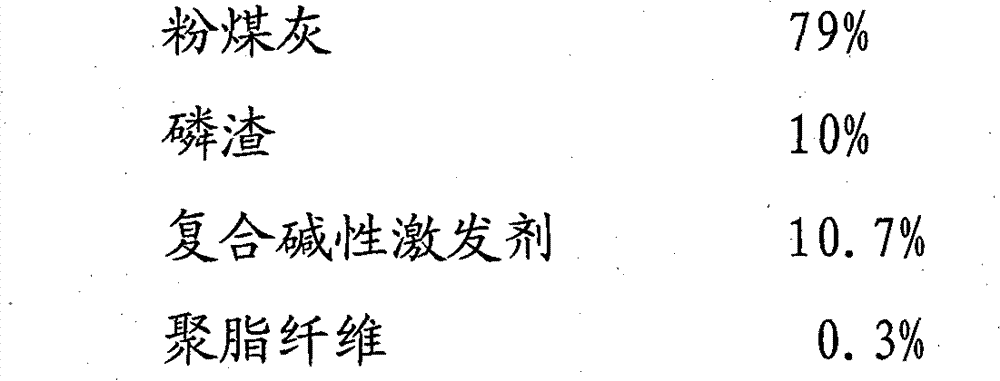

[0027] 1. Formula and preparation of dry powder slurry

[0028]

[0029] According to the above weight ratio, each component is stirred evenly to prepare a dry powder slurry, wherein the composite alkali activator is to add analytically pure NaOH solution to the industrial water glass solution with a modulus of 3.2, and adjust its modulus to 1.2. Na 2 O content is 9%;

[0030] 2. Preparation of light heat insulation and sound insulation board

[0031] Take 92 parts of the above-mentioned dry powder slurry and 8 parts of EPS granules, mix them well and press them into a mold for molding, demould after 1 day of molding, and maintain at 60°C for 4 days; the EPS granules are made by crushing waste EPS boards into a particle size of 2mm particles.

[0032] 3. Sheet performance

[0033] Bulk density is 800kg / m 3 , the 28d compressive strength is 11.8Mpa, the thermal conductivity is 0.113W / (m K), the average sound absorption coefficient in the low frequency band 200-2000Hz is...

Embodiment 3

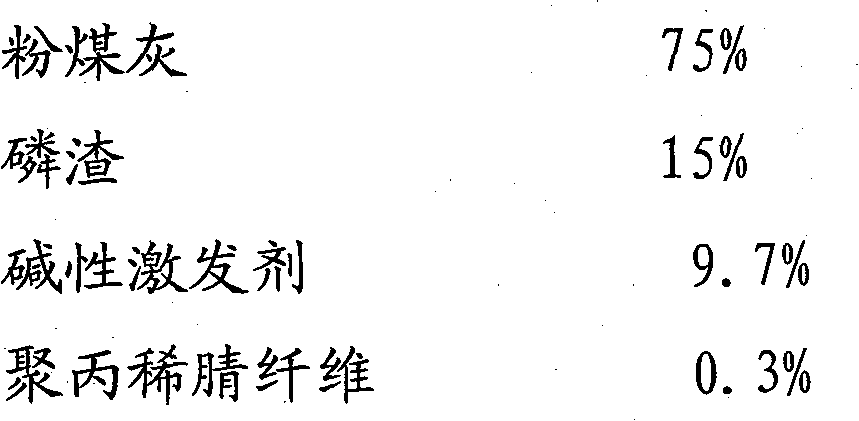

[0035] 1. Formula and preparation of dry powder slurry

[0036]

[0037] According to the above weight ratio, each component is stirred evenly to prepare a dry powder slurry, wherein the composite alkali activator is to add analytically pure NaOH solution to the industrial water glass solution with a modulus of 3.2, and adjust its modulus to 1.2. Na 2 The O content is 9%.

[0038] 2. Preparation of light heat insulation and sound insulation board

[0039] Take 90 parts of the above-mentioned dry powder slurry and 10 parts of EPS granules, mix them well and press them into a mold for molding, demoulding after 1 day of molding, and curing at 60°C for 3 days; the EPS granules are made by crushing waste EPS boards into 4mm particles.

[0040] 3. Sheet performance

[0041] The bulk density is 510kg / m 3 , the 28d compressive strength is 7.1Mpa, the thermal conductivity is 0.087W / (m K), the average sound absorption coefficient in the low frequency band 200-2000Hz is 0.16, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com