Printer thermal transfer ribbon anti-fake method and novel printer

A technology of printers and ribbons, applied in printing, ink ribbons, inking devices, etc., can solve the problems of fake and inferior products, specifications and quality, etc., and achieve the effect of easy structure, simple structure, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

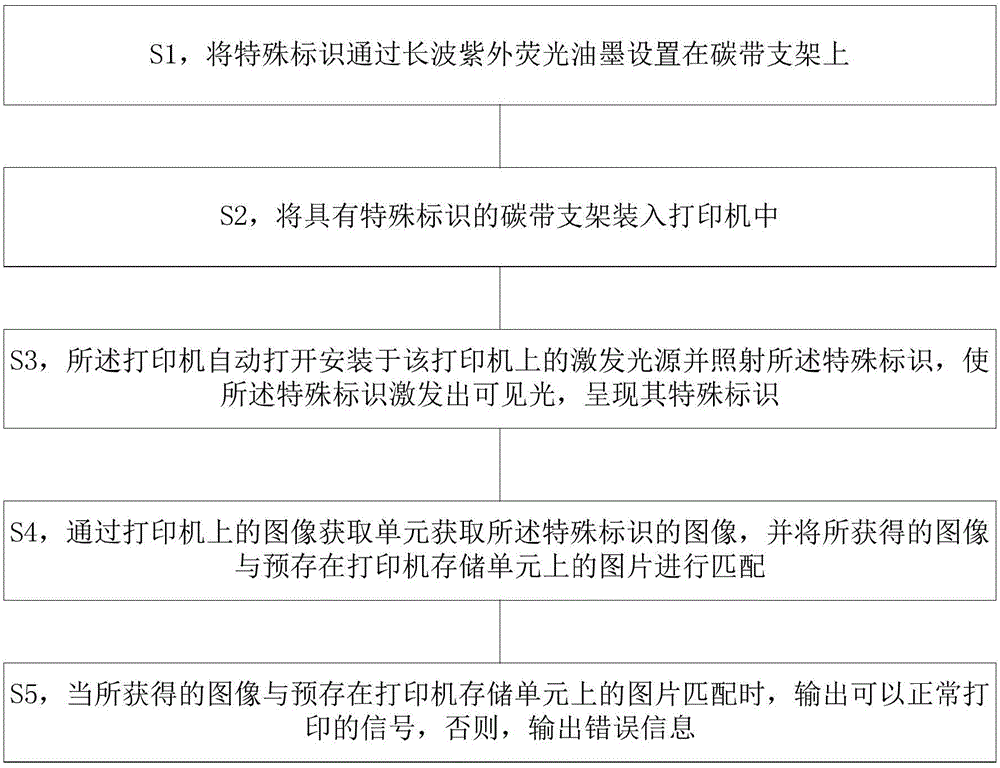

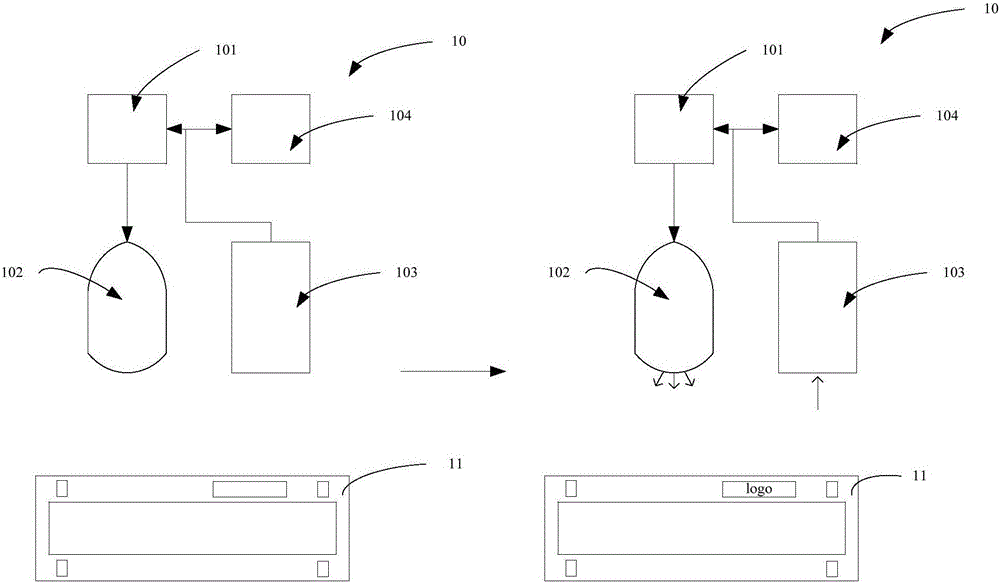

[0029] Please refer to figure 1 , the embodiment of the present invention provides a novel anti-counterfeiting method for a printer ribbon, comprising the following steps:

[0030] S1, setting the special logo on the carbon ribbon holder through long-wave ultraviolet fluorescent ink;

[0031] S2, loading the ribbon holder with special logo into the printer;

[0032] S3, the printer automatically turns on the excitation light source installed on the printer and illuminates the special mark, so that the special mark excites visible light to present its special mark;

[0033] S4, acquire the image of the special logo through the image acquisition unit on the printer, and match the acquired image with the picture pre-stored on the storage unit of the printer; and

[0034] S5, when the obtained image matches the image pre-stored in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com