A ship side plate embedded single column cable structure and its assembly method

An embedded and side panel technology, which is applied to ships and other directions, can solve the problems of large tensile force, heavy cable force, and easy tearing, and achieve the effects of increasing tensile strength, improving safety, and avoiding tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

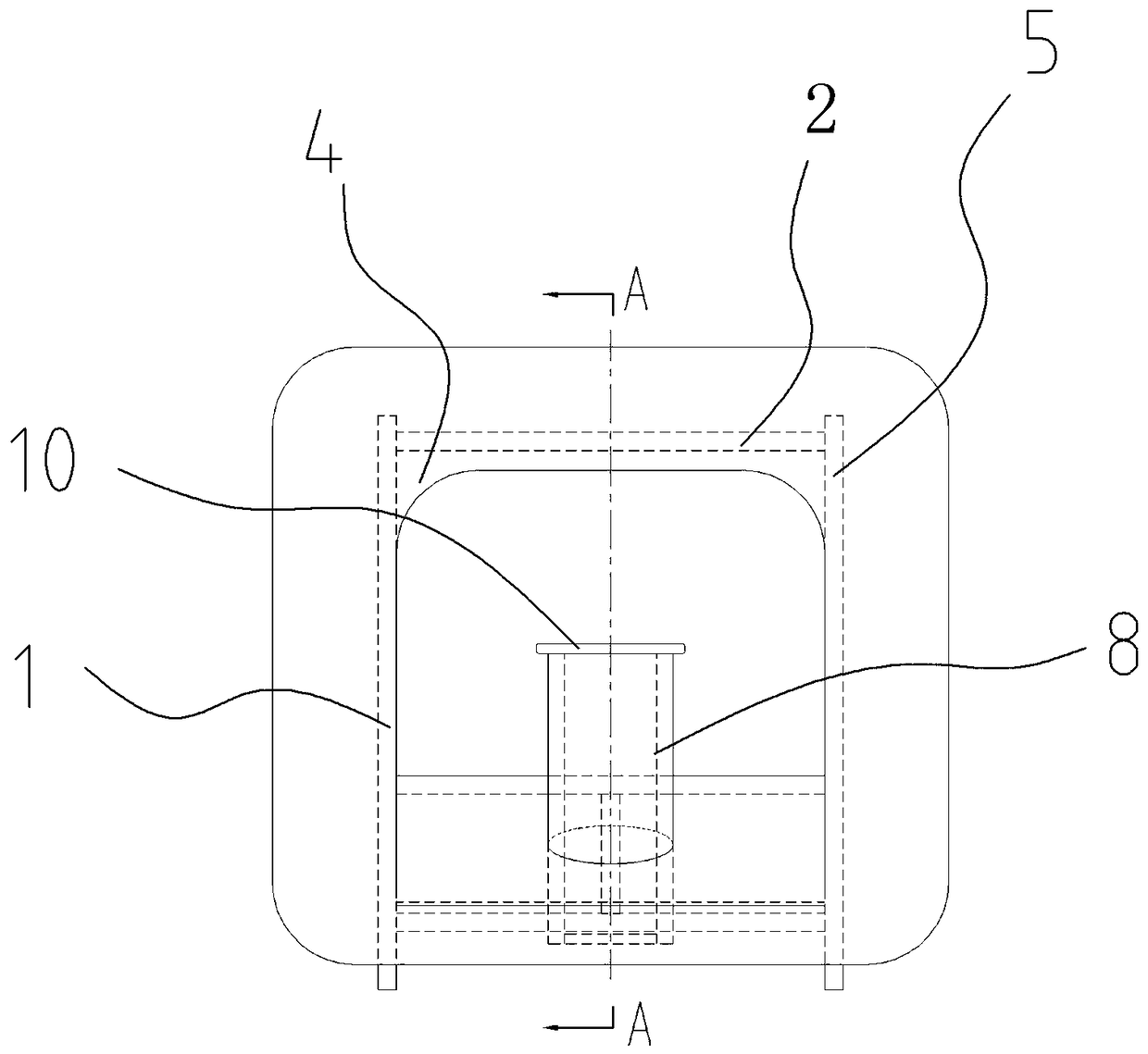

[0019] A ship side plate embedded single-column cable structure, such as figure 1 and figure 2 As shown, it includes a groove arranged on the side plate of the hull, and the left wall plate 1 and the right wall plate 5 connected with the two opposite side walls of the groove are respectively arranged in the groove, and between the left wall plate 1 and the right wall plate 5 The upper sealing plate 2 and the lower sealing plate 3 are connected vertically in sequence, and the upper sealing plate 2 and the lower sealing plate 3 are connected as one through the rear sealing plate 6. The left wall plate 1, the right wall plate 5, the upper sealing plate 2 and the The lower sealing plate 3 is connected with the panel 4 at the same time, and the panel 4 is provided with a port communicating with the cavity surrounded by the upper sealing plate 2, the lower sealing plate 3 and the rear sealing plate 6, and the communication port between the rear sealing plate 6 and the panel 4 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com