Chain bucket reclaiming equipment and corresponding ship unloader

A chain bucket and equipment technology, applied in the field of reclaiming equipment, can solve the problems of ineffective unloading, structural damage, low utilization rate of the wharf, etc., and achieve the effect of improving the efficiency of unloading, controlling dust overflow, and high utilization rate of wharf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, in conjunction with the accompanying drawings, a preferred embodiment is described in detail to further illustrate the present invention.

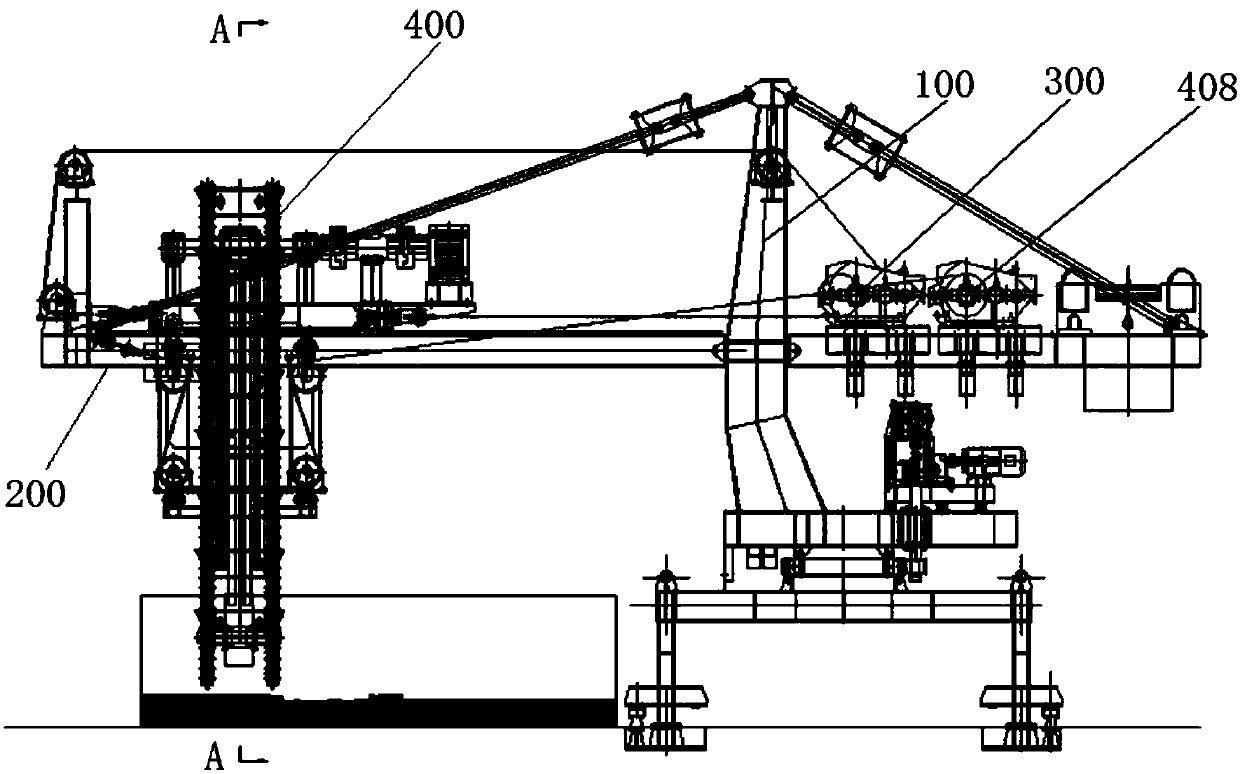

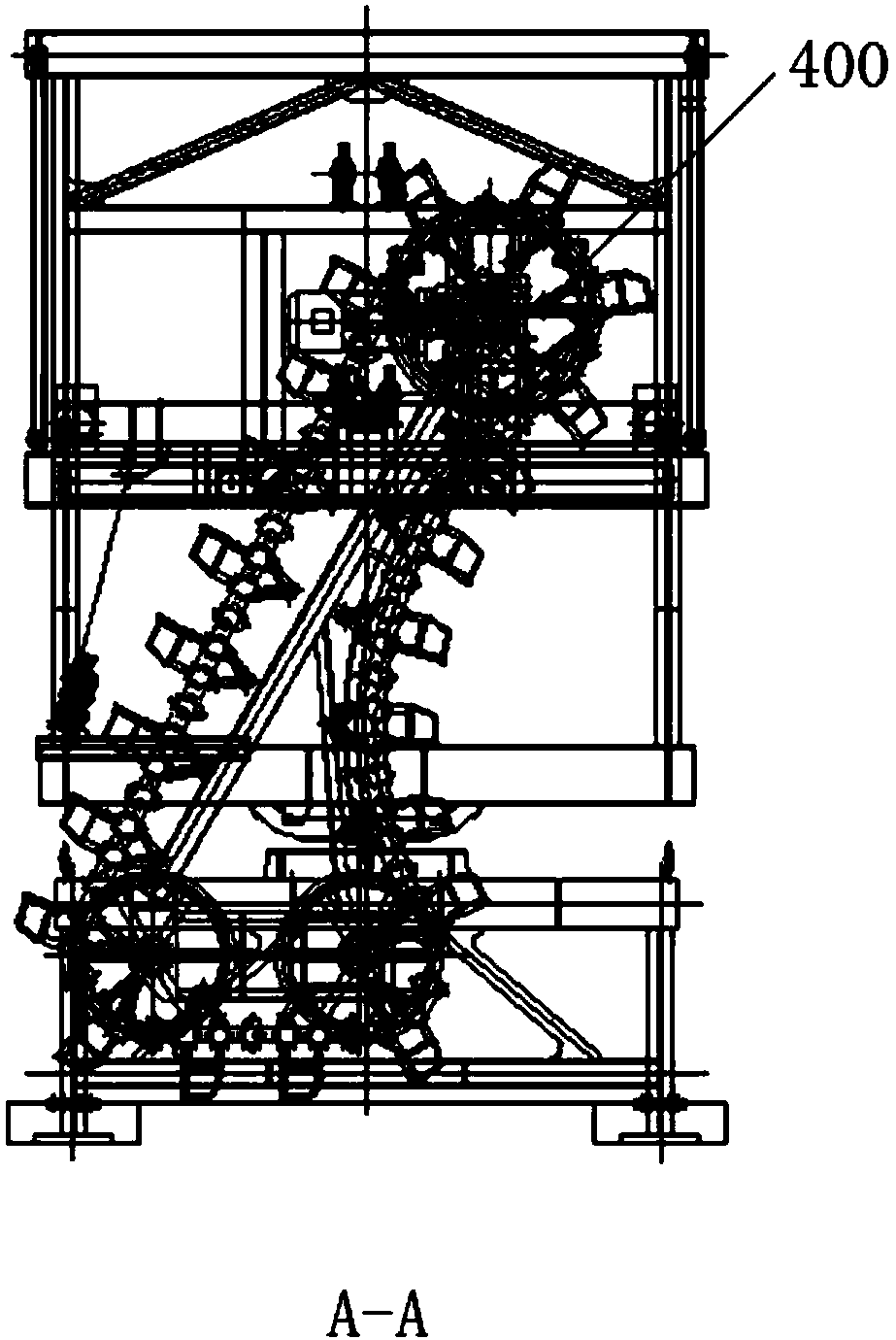

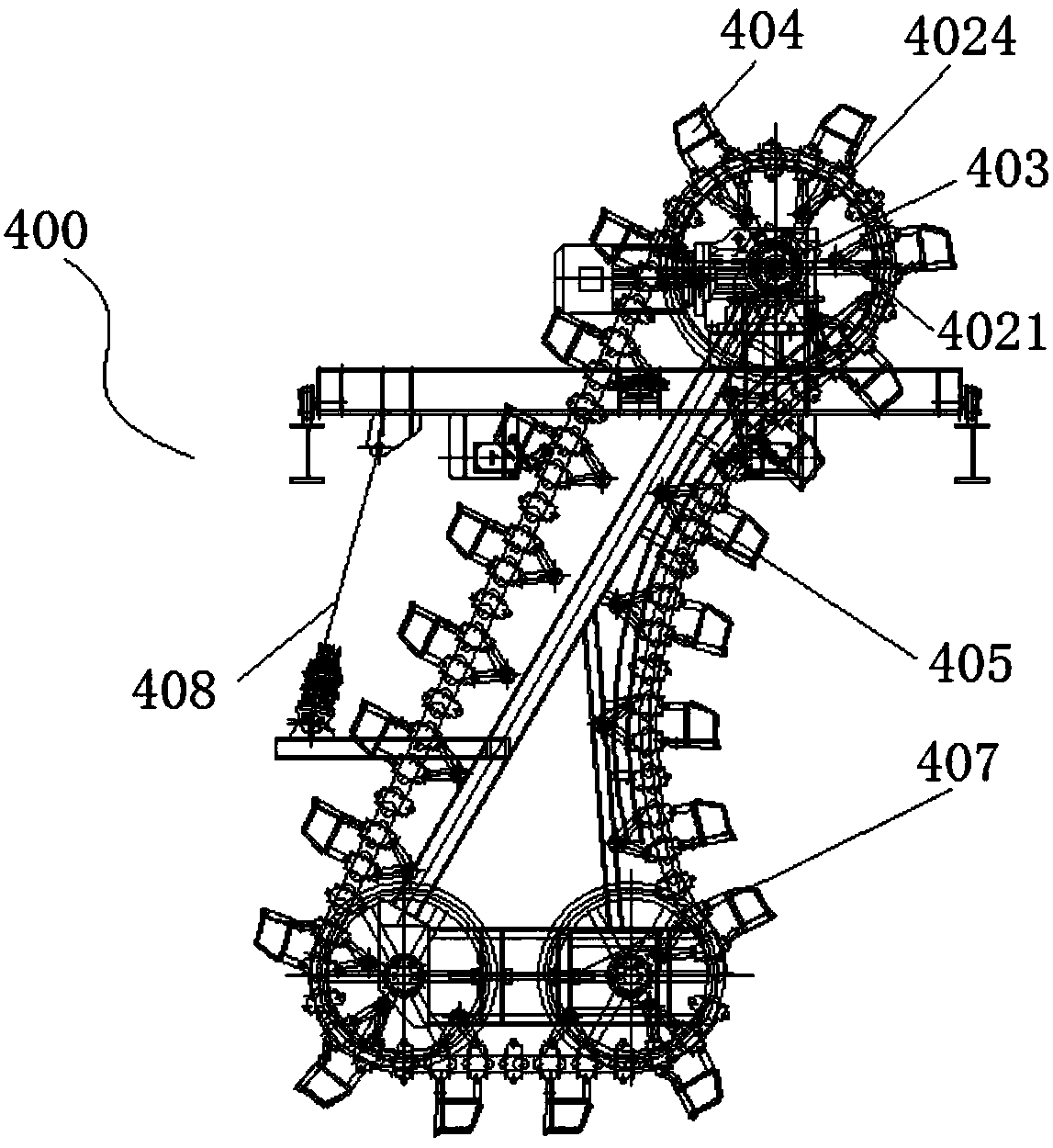

[0033] Such as figure 1 And combine Figure 2 ~ Figure 7 As shown, a chain bucket reclaiming equipment includes: a door frame type equipment support structure 100 configured as a carrying device of the chain bucket reclaiming equipment; a main beam 200 arranged on the equipment support structure 100; a trolley 300, A small frame is arranged on the main beam 200, and the small frame can reciprocate along a track set on the main beam 200; the material reclaiming device 400 passes through the main beam 200 and Vertical to the main beam 200, the reclaiming device 400 is connected to the trolley frame. When the reclaiming position of the reclaiming device 400 needs to be changed, the reclaiming device 400 is pulled by the movement of the trolley 300, Move the reclaiming device 400 to a desired location; for large bulk carriers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com