Working platform leveling device of hydraulic aerial cage

A technology for aerial work vehicles and work platforms, which is applied in the direction of lifting devices, etc., can solve the problems of poor self-weight balance of work buckets, potential safety hazards, and the leveling of work platforms that are only suitable for folding arm type aerial work vehicles, so as to reduce the difficulty of assembly. and production costs, ease of assembly and manufacture, compactness in space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

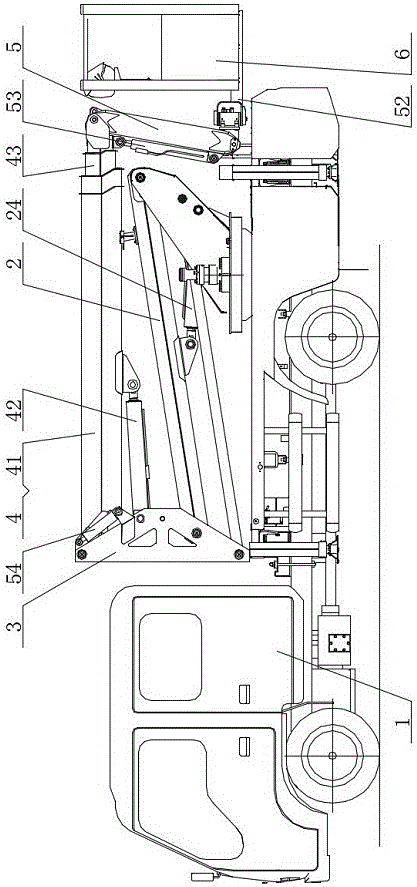

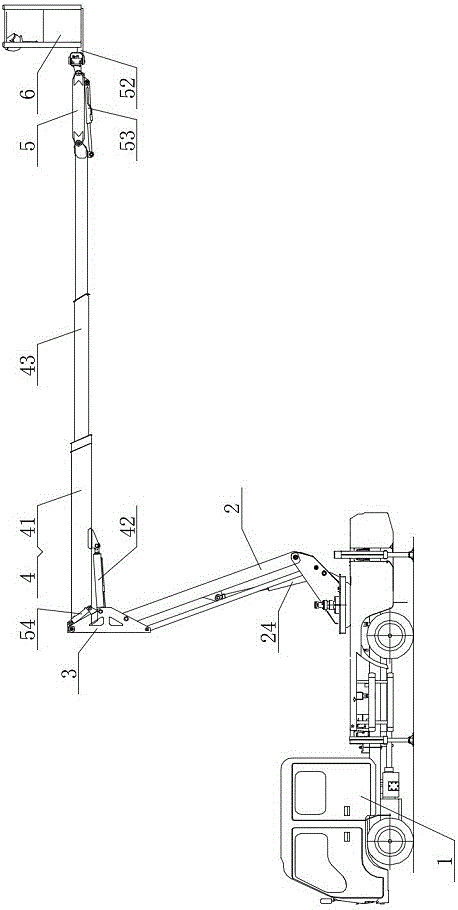

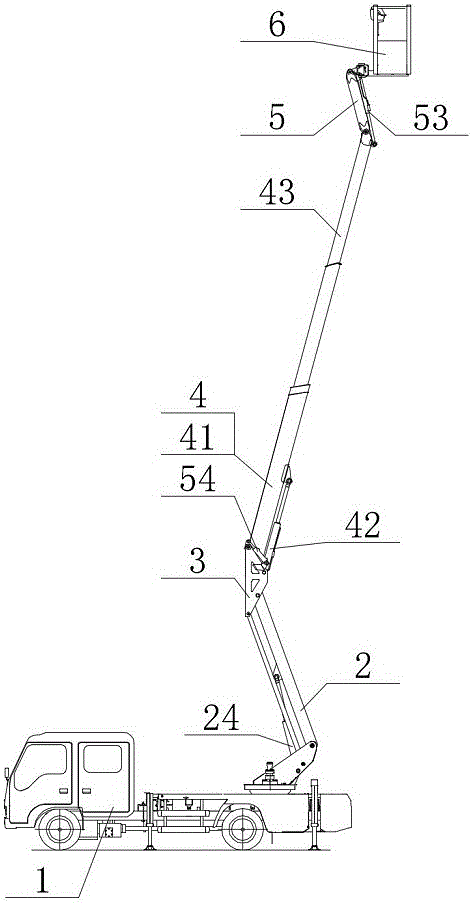

[0026] The present invention will be further described below in conjunction with the accompanying drawings (hereinafter, the normal driving direction of the aerial work vehicle is described as the front).

[0027] Such as Figure 4 As shown, the working platform leveling device 5 of the aerial work vehicle includes a connecting rod crank arm 51 , a bracket 52 , a crank arm luffing cylinder 53 , a primary leveling hydraulic cylinder 54 and a secondary leveling hydraulic cylinder 55 .

[0028]The link type crank arm 51 includes a first connecting frame 511, a first pull rod 512, a second pull rod 513 and a second connecting frame 514; the first connecting frame 511 is provided with four hinges of B, C, D and E Points, hinge points B, D, E are arranged around the hinge point C around the hinge point C, and the link type crank arm 51 is hingedly connected to the end section of the telescopic arm or the folding arm through the hinge point C as a whole; the second connecting frame 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com