A light-weight thermal insulation wallboard containing solid waste coal slag and its preparation process

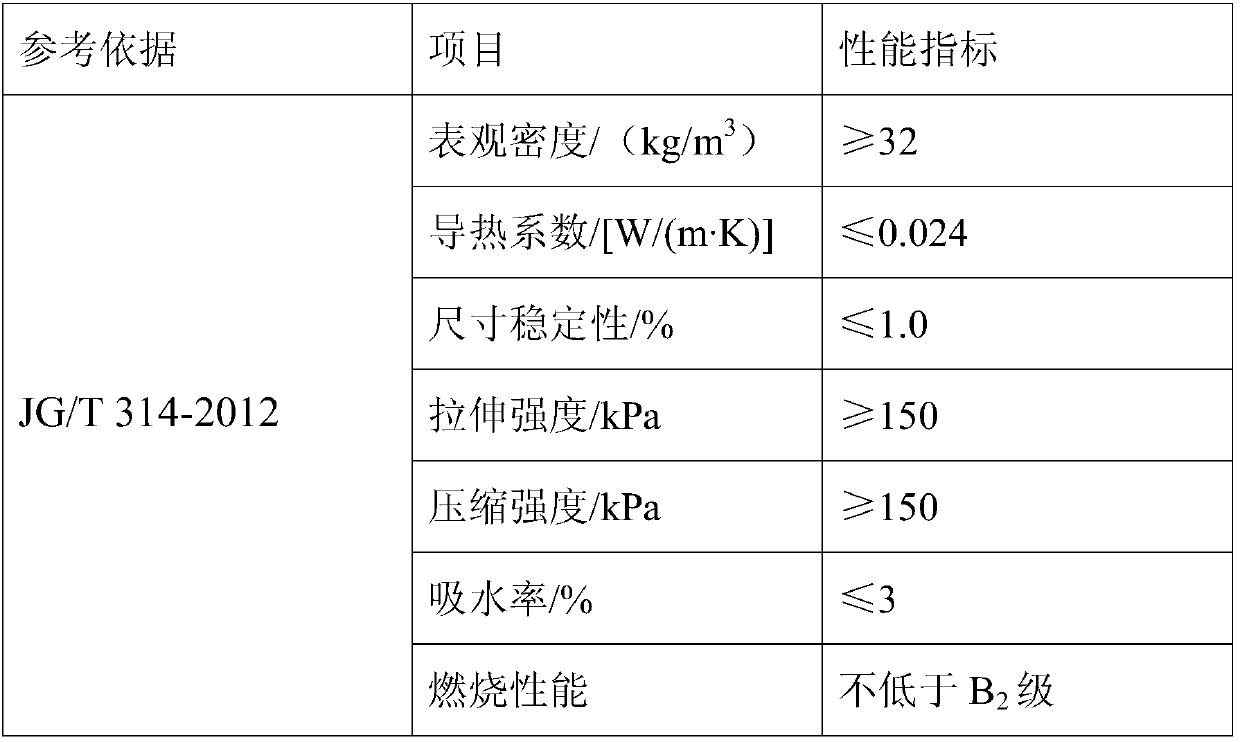

A kind of thermal insulation wallboard, light-weight technology, applied in the field of building thermal insulation and flame retardant materials, can solve the problems of poor bonding, easy falling off of the inorganic shell, poor fireproof performance, etc., achieve good hardening, good thermal insulation performance, and reduce use volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh according to the mass parts of each component, 22 parts of cinder, 4 parts of bentonite, 1 part of polyacrylamide, 0.8 part of polyacryloxyethyltrimethylammonium chloride, 1.2 parts of sodium silicate, polyvinyl alcohol (the number average molecular weight is 20,000) 0.9 parts, 0.7 parts of butylene glycol, 0.8 parts of silane coupling agent, 40 parts of surface-modified polyurethane particles, 30 parts of high alumina cement, and appropriate amount of water.

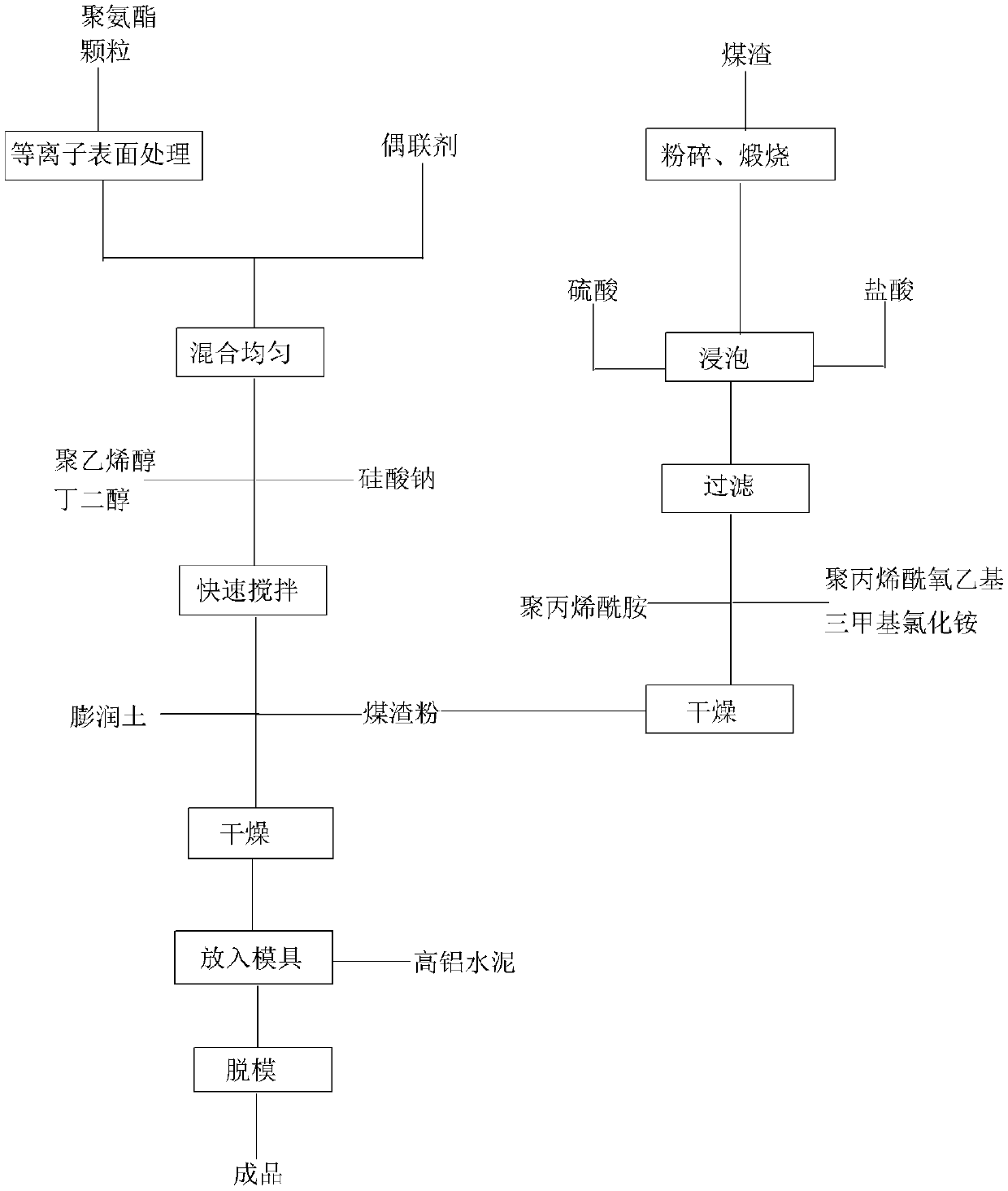

[0032] The preparation method comprises the following steps:

[0033] (1) Cinder treatment and modification: Crush the cinder into cinder powder with a particle size of less than 0.3mm; put the cinder powder into an electric furnace for calcination, treat it at 900°C for 0.8 hours, take it out and grind it again; put the cinder powder into the 15% HCl, 8.5% H 2 SO 4 Soak in the mixed solution for 3 hours, filter, wash with water until neutral, and dry;

[0034] (2) Prepare a mixed solution containing 4.0...

Embodiment 2

[0039] Weigh according to the mass parts of each component, 15 parts of cinder, 3 parts of bentonite, 0.8 part of polyacrylamide, 0.5 part of polyacryloyloxyethyltrimethylammonium chloride, 0.9 part of sodium silicate, polyvinyl alcohol (the number average molecular weight is 130,000) 0.8 parts, 0.3 parts of butanediol, 0.3 parts of silane coupling agent, 35 parts of surface-modified polyurethane particles, 25 parts of high alumina cement, and appropriate amount of water.

[0040] The preparation method comprises the following steps:

[0041] (1) Coal cinder treatment and modification: pulverize the cinder into cinder powder with a particle size of less than 0.3mm; put the cinder powder into an electric furnace for calcination, treat it at 850°C for 0.5 hours, take it out and grind it again; put the cinder powder into the 12% HCl, 8% H 2 SO 4 Soak in the mixed solution for 2 hours, filter, wash with water until neutral, and dry; prepare a mixed solution containing 3% polyacr...

Embodiment 3

[0046] Weigh according to the parts by weight of each component, 25 parts of cinder, 5 parts of bentonite, 1.2 parts of polyacrylamide, 1.0 part of polyacryloyloxyethyltrimethylammonium chloride, 1.5 parts of sodium silicate, polyvinyl alcohol (the number average molecular weight is 200,000) 1.5 parts, 0.8 parts of butanediol, 1.0 parts of silane coupling agent, 45 parts of surface-modified polyurethane particles, 35 parts of high alumina cement, and appropriate amount of water.

[0047] The preparation method comprises the following steps:

[0048] (1) Coal slag treatment and modification: Grind the coal slag into cinder powder with a particle size of less than 0.3mm; put the cinder powder into an electric furnace for calcination, treat it at 955°C for 1 hour, take it out and grind it again; put the cinder powder into the 20% HCl, 10% H 2 SO 4 Soak in the mixed solution for 4 hours, filter, wash with water until neutral, and dry; prepare a mixed solution containing 4.5% pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com