Liquid dispensing device and absorption type cold and hot water machine equipped with liquid dispensing device

A liquid distribution device, hot and cold water machine technology, applied in the direction of adsorption machines, refrigerators, refrigeration components, etc., can solve the problem of reducing heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the liquid distributing device of the absorption type chiller and hot water machine according to the embodiment of the present invention will be described in detail with reference to the drawings.

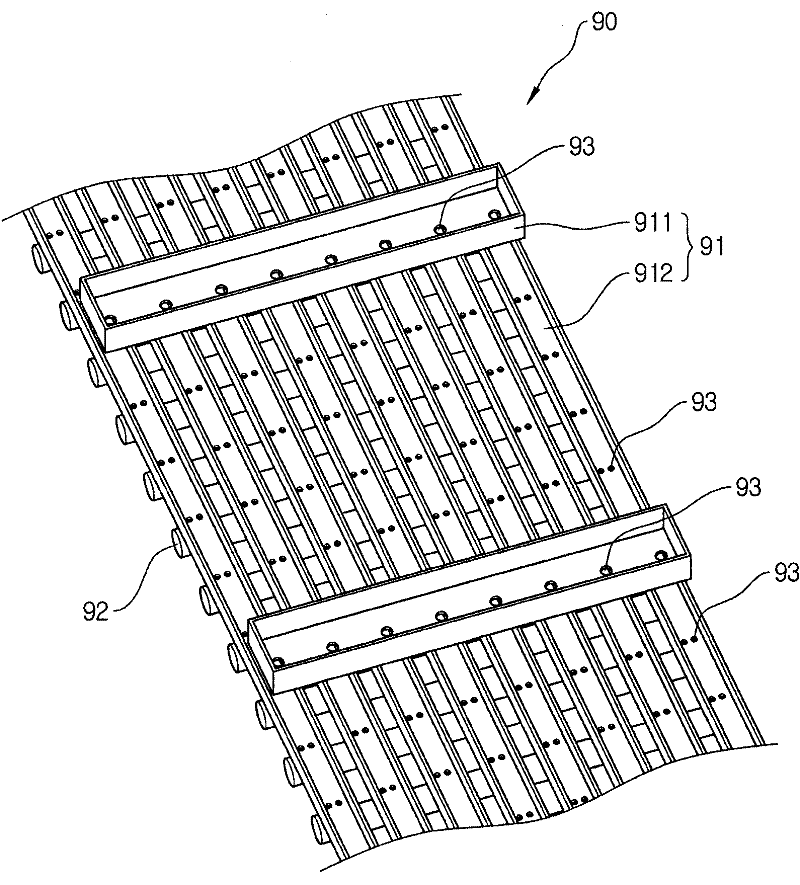

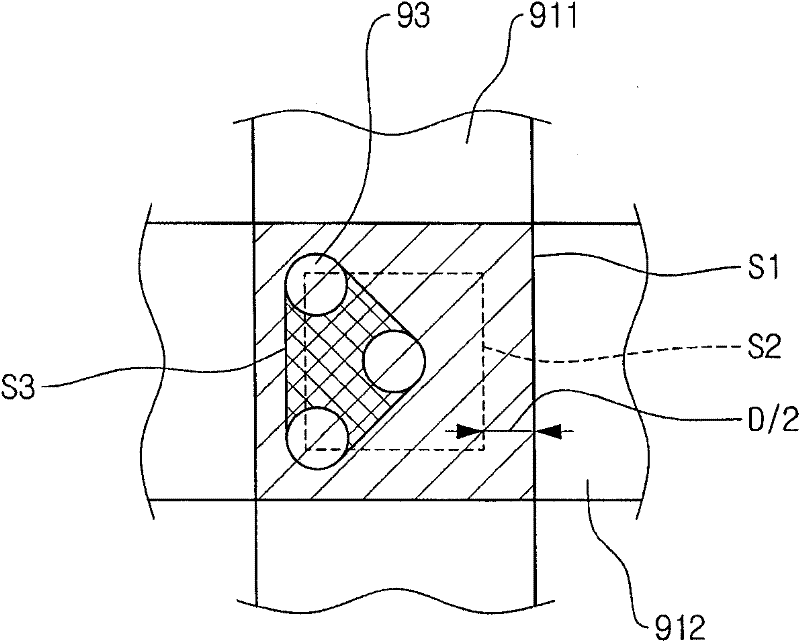

[0029] figure 2 It is a partial perspective view of the liquid distribution device of the absorption type cold and hot water machine according to the embodiment of the present invention, Figure 3 to Figure 5 It is a figure showing the arrangement of various dispensing ports.

[0030] refer to figure 2 , The liquid distribution device 90 according to the embodiment of the present invention has a rectangular chute 91 with an open top. A plurality of distribution ports 93 are formed at intervals on the bottom surface of the chute 91 for allowing liquid to flow to the heat transfer tubes 92 arranged at the lower portion. The shape of the dispensing port 93 may be various shapes such as a circle and a polygon, but a circle is preferable.

[0031] The chute 91 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com