A technology for reducing surface density of paper-faced gypsum board

A paper-faced gypsum and board surface technology is applied in the technical field of reducing the surface density of the paper-faced gypsum board, which can solve the problems of low edge hardness, reduced surface density, non-conformity, etc., so as to improve the sound insulation and heat insulation performance and reduce the amount of gypsum. , The effect of easier construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

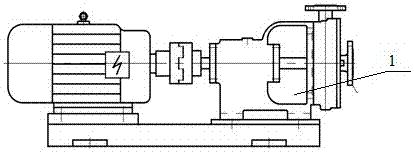

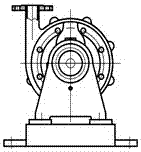

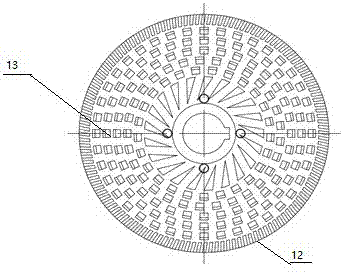

Image

Examples

Embodiment 1

[0050] Example 1: In the gypsum board preparation process, the proportioning is carried out according to the following ratio. For every 100kg of construction gypsum powder, 60kg of slurry water, 10kg of active mild agent, 0.2kg of gypsum crystal converter, 0.2kg of refining catalyst, crystal 0.2kg of retaining agent, 0.3kg of crystal strengthening agent, 0.1kg of crystal surface protecting agent, 0.3kg of water reducing agent, 0.3 kg of fiber reinforcing agent, 0.03 kg of surfactant, and 0.03 kg of coagulation regulator; Dilute 0.3% of the surfactant diluent, and fully mix the fine bubbles produced by the foaming system according to the gas-liquid volume ratio of 19:1 in the mixer. Combined to form a gypsum slab for paper surface, after being cut, it is dried in a gypsum board drying kiln at 240-260 ° C to become a gypsum board for paper surface.

[0051] The paper-faced gypsum board made by this scheme has an areal density of 6.0 kg / ㎡ (folding δ9.5mm), a longitudinal flexural...

Embodiment 2

[0052] Embodiment 2: In the gypsum board preparation process, the proportioning is carried out according to the following ratio. For every 100kg of building gypsum powder, 40kg of slurry water, 30kg of active mild agent, 0.4kg of gypsum crystal converter, 1.5kg of refining catalyst, crystal 0.6kg of retaining agent, 1kg of crystal strengthening agent, 0.5kg of crystal surface protecting agent, 0.8kg of water reducer, 1.5kg of fiber reinforcing agent, 0.08kg of surfactant, and 0.05kg of coagulation regulator; 0.3% surfactant diluent, according to the gas-liquid volume ratio of 15:1, the fine bubbles produced by the foaming system are fully mixed in the mixer, and the sticky edge white latex is added to bond with the upper and lower layers of protective paper through pressure molding Form the gypsum slab with paper surface, and after being cut, dry it in a gypsum board drying kiln at 240-260°C to become a gypsum board with paper surface.

[0053] The paper-faced gypsum board mad...

Embodiment 3

[0054] Example 3: In the gypsum board preparation process, the proportioning is carried out according to the following proportions: for every 100 kg of building gypsum powder, 55 kg of slurry water, 10 kg of active mild agent, 0.3 kg of gypsum crystal converter, 1.0 kg of refining catalyst, and crystal 0.3kg of retaining agent, 0.6kg of crystal strengthening agent, 0.3kg of crystal surface protecting agent, 0.6kg of water reducing agent, 0.8 kg of fiber reinforcing agent, 0.05 kg of surfactant, and 0.05 kg of coagulation regulator; Dilute 0.35% of the surfactant diluent, mix the fine bubbles produced by the foaming system according to the gas-liquid volume ratio of 10:1, and then fully mix them in the mixer. Combined to form a gypsum slab for paper surface, after being cut, it is dried in a gypsum board drying kiln at 240-260 ° C to become a gypsum board for paper surface.

[0055] The paper-faced gypsum board made by this scheme has an areal density of 5.6 kg / ㎡ (folding δ9.5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com