A kind of silver-modified titanium dioxide nanotube composite anode and preparation method thereof

A nanotube composite and titanium dioxide technology, which is applied in the field of electrochemistry, can solve the problems of poor conductivity, short service life, and increased energy consumption, and achieve the effects of reducing ohmic voltage drop, long service life, and lower potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

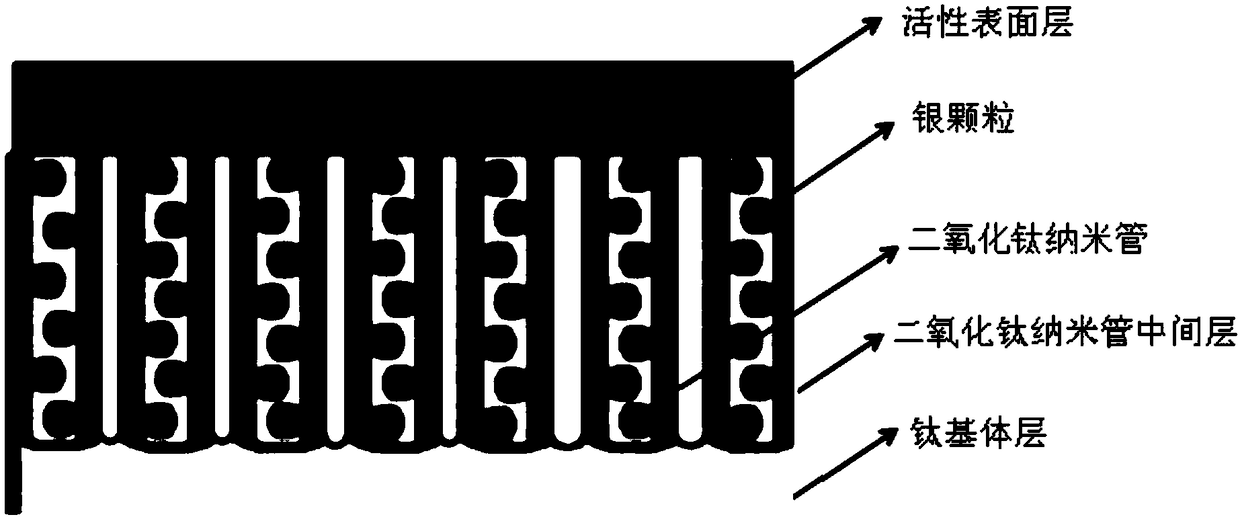

[0033] A kind of silver-modified titanium dioxide nanotube composite anode of the present invention, its structural schematic diagram is as figure 1 As shown, including the titanium matrix layer (pure titanium plate), the middle layer of titanium dioxide nanotubes and the active surface layer (MnO 2 layer), wherein the intermediate layer of titanium dioxide nanotubes is decorated with metallic silver in the form of a network.

[0034] The preparation method of the silver-modified titanium dioxide nanotube composite anode of the present embodiment comprises the following steps:

[0035] (1) Polish the pure titanium sheet with 360#, 600#, 800#, and 1000# sandpaper in sequence, then ultrasonically clean it with acetone, ethanol, and deionized water for 10 minutes, and then put the polished titanium sheet into HF : HNO 3 = 1:2 mixed acid solution for activation 30s cleaning, drying;

[0036] (2) With the pure titanium sheet processed in step (1) as the anode and the graphite as...

Embodiment 2

[0041] A kind of silver-modified titanium dioxide nanotube composite anode of the present invention, its structural schematic diagram is as figure 1 As shown, including the titanium matrix layer (pure titanium plate), the middle layer of titanium dioxide nanotubes and the active surface layer (RuO 2 layer), wherein the intermediate layer of titanium dioxide nanotubes is decorated with metallic silver in the form of a network.

[0042] The preparation method of the silver-modified titanium dioxide nanotube composite anode of the present embodiment comprises the following steps:

[0043] (1) Polish the pure titanium sheet with 360#, 600#, 800#, and 1000# sandpaper in sequence, then ultrasonically clean it with acetone, ethanol, and deionized water for 10 minutes, and then put the polished titanium sheet into HF : HNO 3 = 1:2 mixed acid solution for activation 30s cleaning, drying;

[0044] (2) With the pure titanium sheet processed in step (1) as the anode and the graphite as...

Embodiment 3

[0049] A kind of silver-modified titanium dioxide nanotube composite anode of the present invention, its structural schematic diagram is as figure 1 As shown, including the titanium matrix layer (pure titanium plate), the middle layer of titanium dioxide nanotubes and the active surface layer (SnO 2 layer), wherein the intermediate layer of titanium dioxide nanotubes is decorated with metallic silver in the form of a network.

[0050] The preparation method of the silver-modified titanium dioxide nanotube composite anode of the present embodiment comprises the following steps:

[0051] (1) Polish the pure titanium sheet with 360#, 600#, 800#, and 1000# sandpaper in sequence, then ultrasonically clean it with acetone, ethanol, and deionized water for 10 minutes, and then put the polished titanium sheet into HF : HNO 3 = 1:2 mixed acid solution for activation 30s cleaning, drying;

[0052] (2) With the pure titanium sheet processed in step (1) as the anode and the graphite as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com