High-position beam falling construction method in box beam erection

A construction method and box girder technology, applied in the erection/assembly of bridges, bridge construction, bridges, etc., can solve the problems of idle equipment in the field, prolong the construction period, and increase the construction cost, so as to avoid idle equipment, save construction period, The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

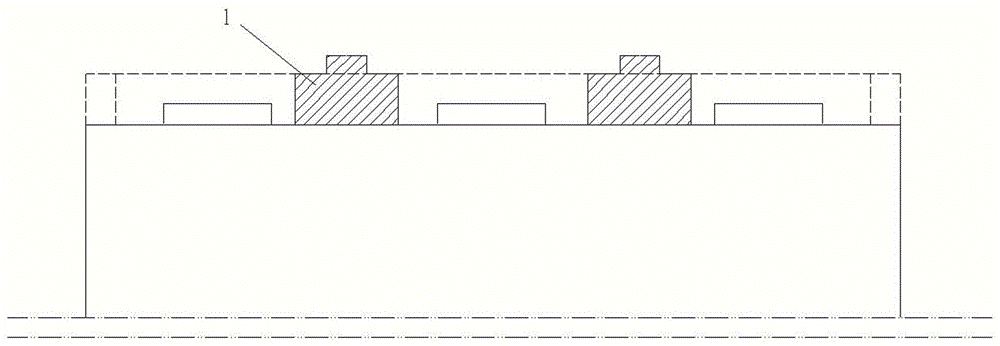

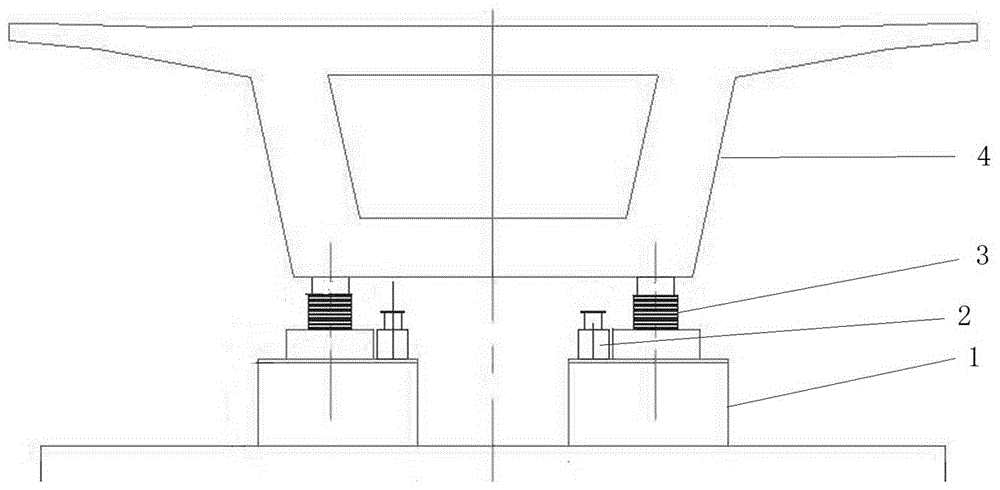

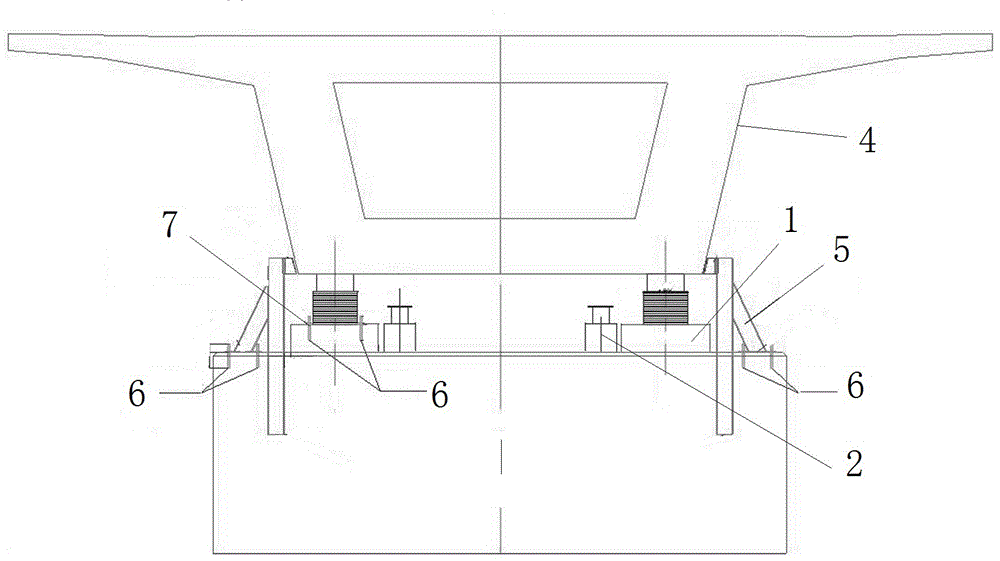

[0032] In the present invention, the box girder to be erected is aligned by the bridge erecting machine and the beam transport vehicle, the bridge erecting machine is returned, and then four 500T jacks are used to raise the top of the box girder to 420mm higher than the design elevation, and the four jacks are withdrawn after the alignment of the bottom of the beam is completed. (If you wait for the stretching time of the continuous beam within 7 days, the jack will not be withdrawn), carry out the stretching of the longitudinal prestressed beam of the continuous beam. position, carry out support mortar pouring. In the process of high-level storage, jacking and beam drop of the box girder, measures are taken to temporarily fix the expansion joints at four positions on both sides to prevent the box girder from sliding vertically and ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com