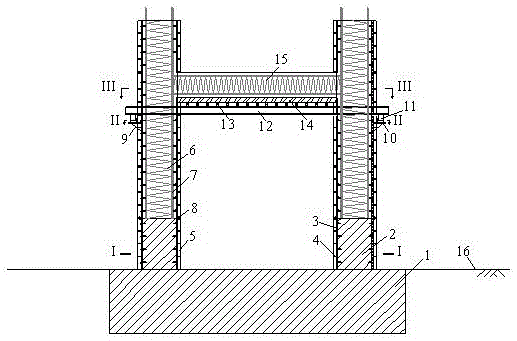

Pier column and cross tie beam synchronous pouring supporting formwork structure and construction method thereof

A technology of simultaneous pouring and transverse tie beams is applied in the field of bridge pier column construction, which can solve the problems of poor adaptability to the height change of transverse tie beams, long construction period, and inability to reuse, so as to ensure streamlined construction operations and facilitate mold-turning construction. , the effect of improving the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] A bridge adopts double-leg pier columns with a diameter of 1.2m, a height of 15m, and a distance of 5m. The cross-section of the transverse beam is 1.0×0.8m.

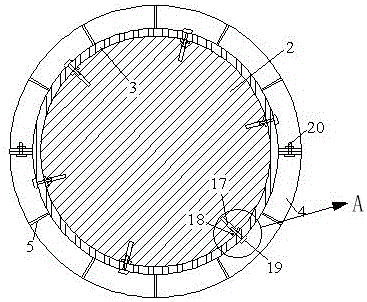

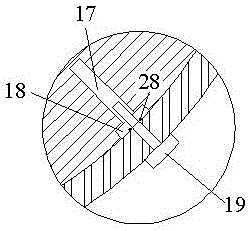

[0043] Segmented pier column formwork 3 is made of two semicircular formwork fastened by horizontal connecting bolts 20, with an inner diameter of 1.2m, a thickness of 8mm, and a length of 2m; the outer side is uniformly welded with transverse ribs 4 and vertical ribs 5, and its cross-sectional size is 50× 6mm. The segmented pier formwork 3 is evenly provided with screw through holes, one end of the pre-embedded internal thread positioning rod 17 is welded to the longitudinal rib 7 of the pier column, and the other end is welded to the steel gasket 18 with a sealing ring 28, and the fastening bolt 19 passes through The screw through hole fixes the pier column template 3 on the pier column longitudinal reinforcement 7 .

[0044] The height of the segmented pier column formwork 3 with triangular braces 9 is 4m, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com