Fluidization scouring promotion device based on silt flowing deformation

A sediment and fluidization technology, applied in river regulation, water conservancy engineering, sea area engineering, etc., can solve problems such as difficulty in controlling dredging position and dredging depth, inability to directly shear soil, and difficulty in achieving good results. , to achieve the effect of controllable scope of action, controllable dredging depth, and controllable dredging position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

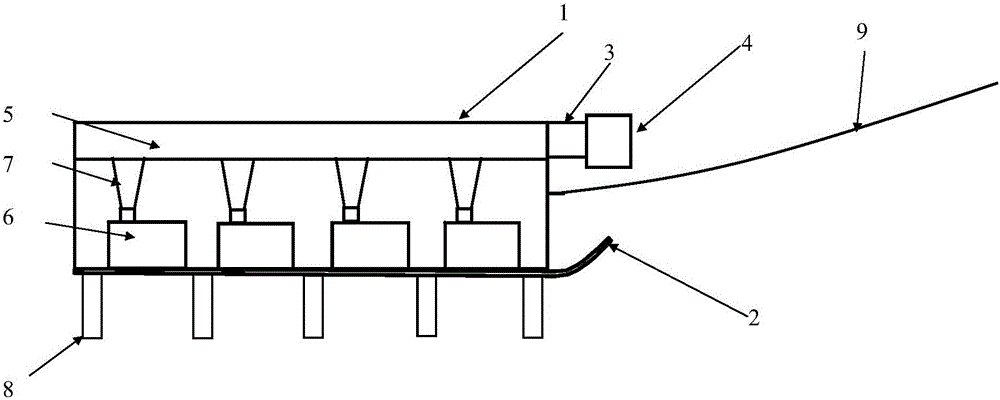

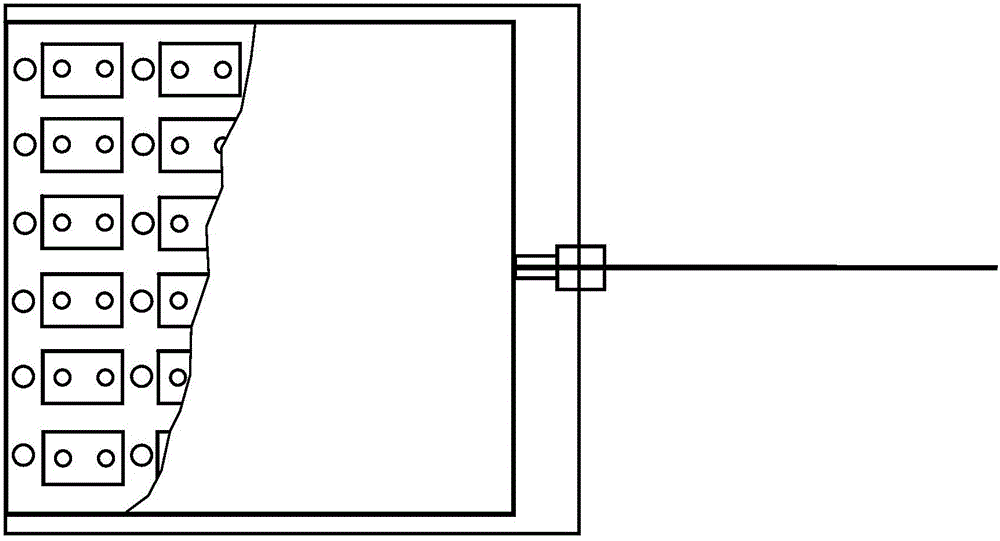

[0030] like Figure 1-2 As shown, this embodiment provides a fluidization boosting device supported by a hydraulic vibrator, which consists of a housing 1, a mud skid 2, an inlet pipe 3, a damping joint 4, a flow supply chamber 5, and a vibration unit 6 , a diversion tube 7, a supplementary flow column 8 and a tow cable 9, wherein: the housing 1 is arranged on the mud skid 2, the upper part of the housing 1 is opened to communicate with the inlet pipe 3, and the bottom of the housing 1 is opened There are several holes in communication with the supplementary flow column 8; the inlet pipe 3 is arranged on the side wall of the front end of the housing 1, and the upper end of the inlet pipe 3 is connected to the damping joint 4; The front end of 5 communicates with the inlet pipe 3, and the lower part of the flow supply chamber 5 communicates with a plurality of guide tubes 7; the vibration unit 6 is arranged at the bottom of the housing 1, and the upper inlet of the vibration un...

Embodiment 2

[0043] Such as Figure 1-2 As shown, this embodiment provides a fluidization boosting device supported by a pneumatic vibrator, which consists of a housing 1, a mud skid 2, an inlet pipe 3, a damping joint 4, a flow chamber 5, a vibration unit 6, The diversion tube 7, the supplementary flow post 8 and the tow cable 9 are composed, wherein: the housing 1 is arranged on the mud skid 2, and the upper opening of the housing 1 communicates with the inlet pipe 3, and several openings are opened at the bottom of the housing 1. The hole communicates with the supplementary flow column 8; the inlet pipe 3 is arranged on the front side wall of the housing 1, and the upper end of the inlet pipe 3 is connected to the damping joint 4; The front end of the front end communicates with the inlet pipe 3, and the lower part of the flow supply chamber 5 communicates with a plurality of guide tubes 7; the vibration unit 6 is arranged at the bottom of the housing 1, and the upper inlet of the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com