Stud anti-shearing connecting piece for constraining concrete splitting and splitting development

A technology for shear-resistant connectors and confining concrete, which is applied in the direction of load-bearing elongated structural components, building components, structural elements, etc., can solve the problems that the advantages of steel and concrete materials cannot be fully utilized, and the widespread application and application are restricted. , to achieve the effect of increasing the effective load, increasing the longitudinal shear bearing capacity, and increasing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

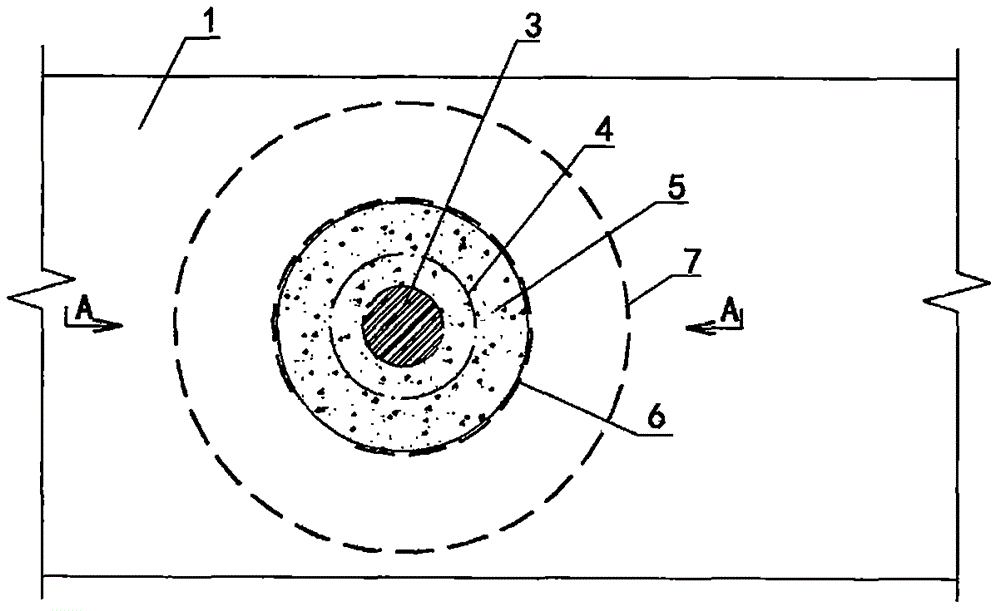

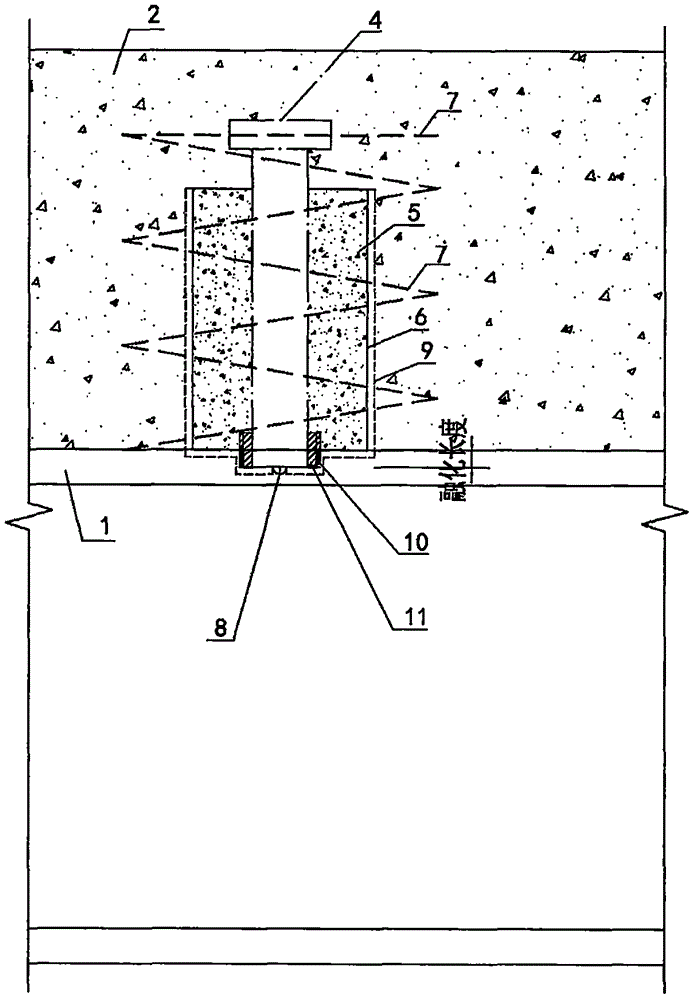

[0033] see Figure 1 to Figure 6 Embodiment 1 of the stud shear connector for constraining concrete splitting and splitting development. In this embodiment, the stud shear connector is made with the stud 3 as the connection basis, and the stud 3 is used in the market 16mm cylindrical head studs are sold, and the root of the welding end of the stud 3 is fitted with a plastic-molded ring-shaped inner tire film 11 with a size structure of 3.5mmx10mm, and a welding auxiliary ring with an inner diameter of 23mm and a thickness of 1mm is also set on the outside of the annular inner tire membrane 11 10, and the stud welding arc point 8 is exposed to the reserved hole in the center of the bottom of the mold. The high-strength fine stone concrete mold 9 with an inner diameter of 48mm is concentrically set on the outside of the stud 3, and the structure is shown as figure 2 As shown, the high-strength fine-stone concrete 5 of C50-C80 is poured in the high-strength fine-stone concrete ...

Embodiment 2

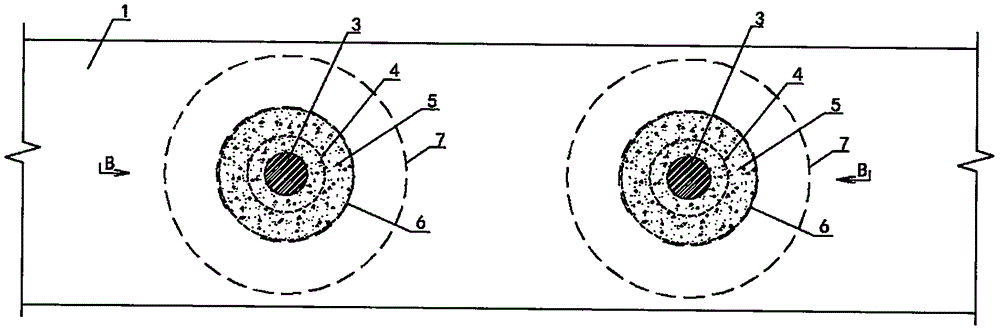

[0040] Figure 7 ~ Figure 13 It is the second embodiment of the present invention. In this embodiment, the stud 3 is a high-strength steel stud with a material performance grade of 10.8. The stud 3 is connected by a pressure-bearing high-strength bolt connection technology, and the stud 3 The cooperating high-strength bolts 19, supporting nuts 20, and connecting threaded surfaces 21 should meet the corresponding requirements of the relevant specifications. Since the stud 3 in the second embodiment uses a 10.8-grade high-strength steel bolt with a diameter of 16mm The nail cooperates with the supporting nut 20 to make a fixed connection with the steel beam flange 1, so this structure puts forward higher requirements for the longitudinal shear of the reinforced concrete flange 2 by the shear connector. The concrete splits within the 3D core range around the stud, which can be used for figure 1 The high-strength fine stone concrete 5 within 48 mm of the core area in the middle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com