Reinforcement structure and construction method of an empty bucket wall

A technology for strengthening structures and construction methods, applied in building construction, construction, building maintenance, etc., can solve problems such as insufficient wall bearing capacity, achieve convenient construction, shorten construction period, and increase integrity and bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and specific embodiments.

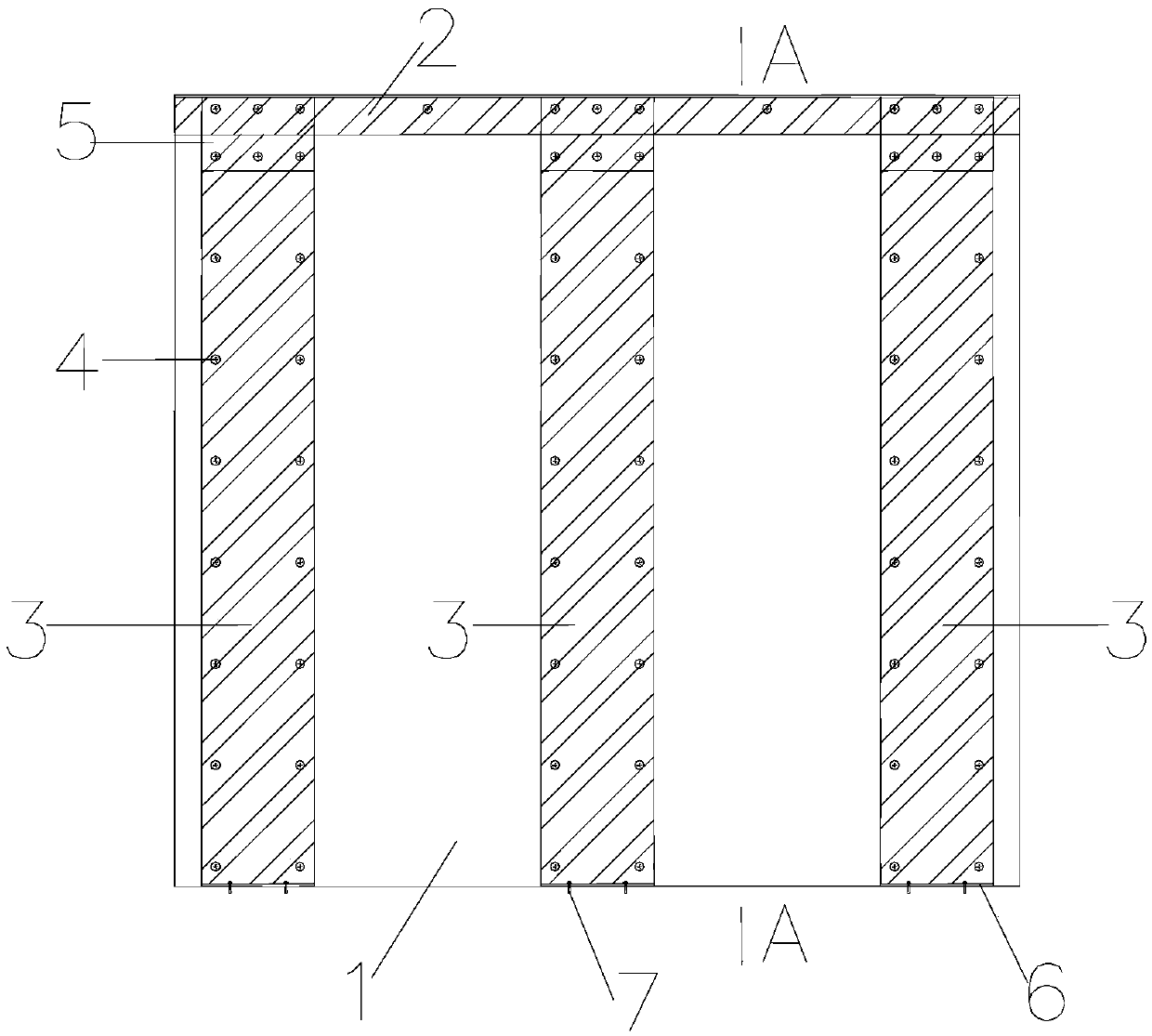

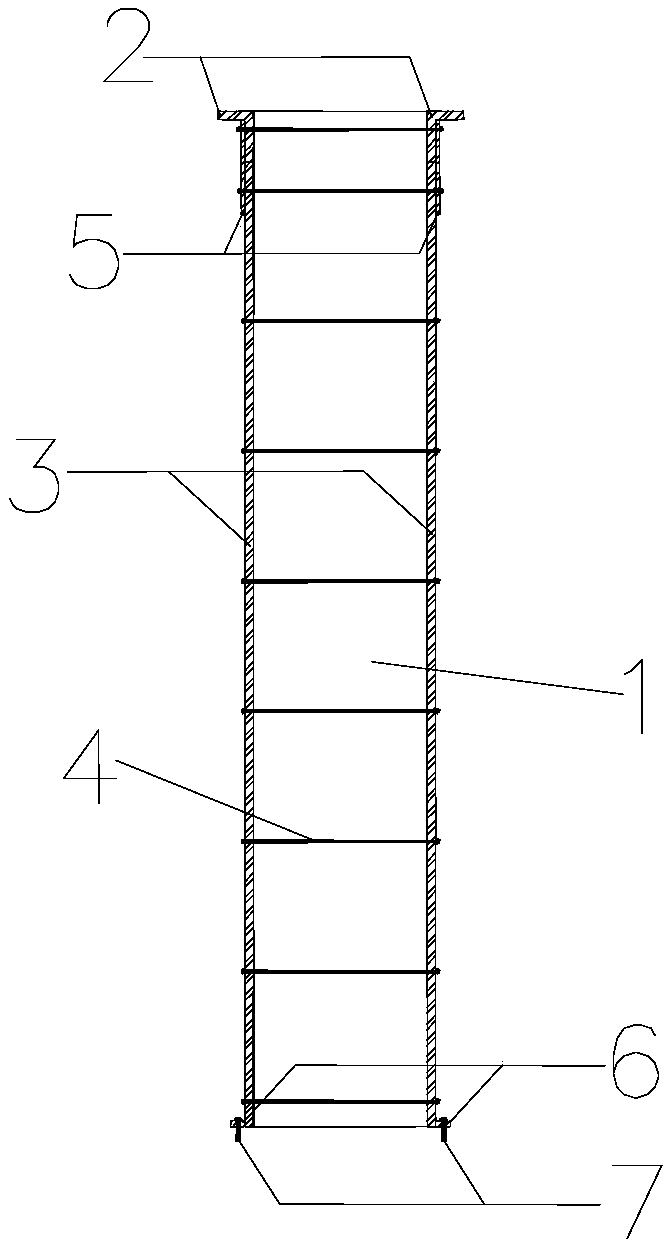

[0024] Such as figure 1 with 2 Shown: a reinforcement structure of an empty bucket wall, including an empty bucket wall 1, angle steel 2, steel strips 3, short steel plates 5, long steel strips 6, butt bolts 4 and chemical anchors 7;

[0025] The walls on both sides of the empty bucket wall 1 are respectively provided with a plurality of vertical and vertical steel plate strips 3, and the upper ends of the walls on both sides of the empty bucket wall 1 are respectively provided with horizontal and horizontal angle steels 2; The belt 3 and the angle steel 2 are both bonded to the empty bucket wall 1 by structural glue, and anchored by the through bolts 4; one limb of the angle steel 2 is flush with the upper surface of the empty bucket wall 1, so that the upper load is transmitted to the same plane Above, the angle steel 2 and the empty bucket wall 1 are under co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com