A tube bundle riser structure assembly

A structural assembly and tube bundle type technology, applied in drill pipes, casings, drill pipes, etc., can solve the problems of difficult coaxial adjustment of post-installation risers, large investment costs, and long installation time, so as to reduce the risk of failure and ensure safety. Good performance, improve installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

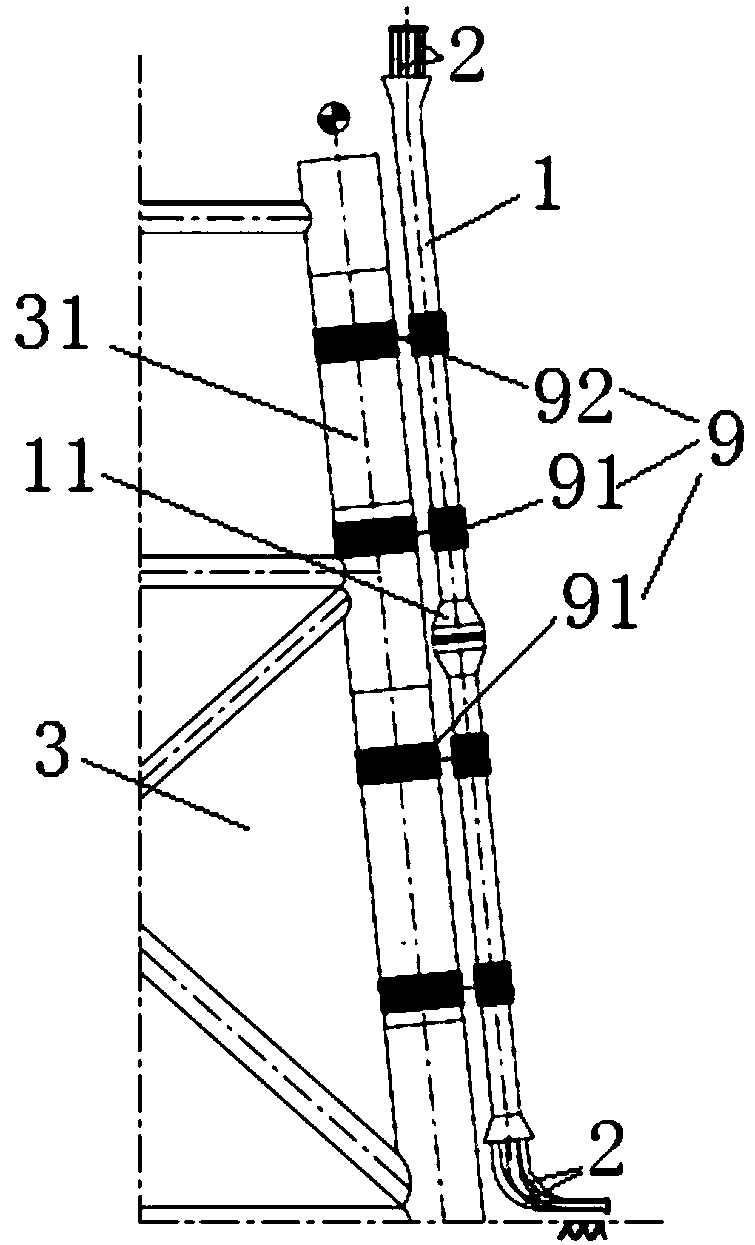

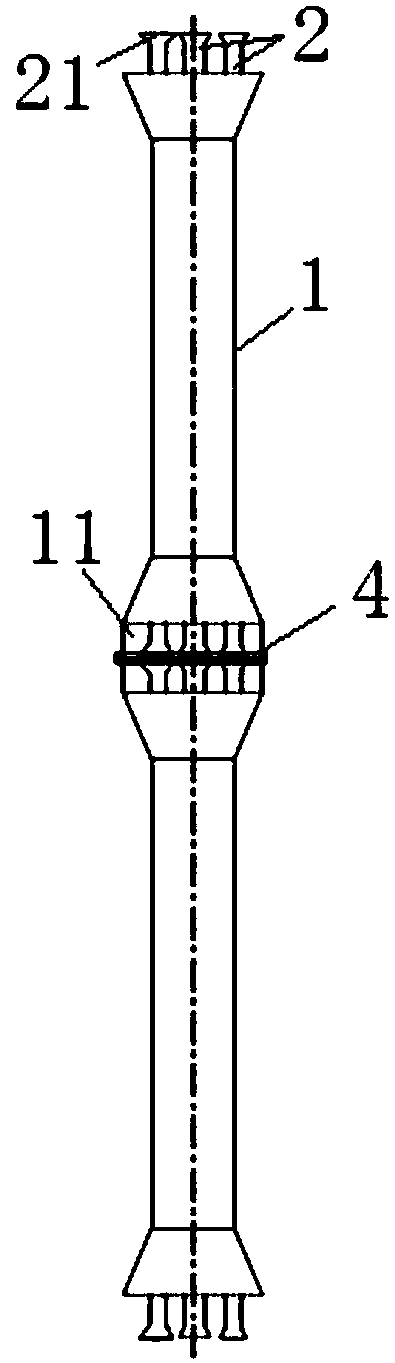

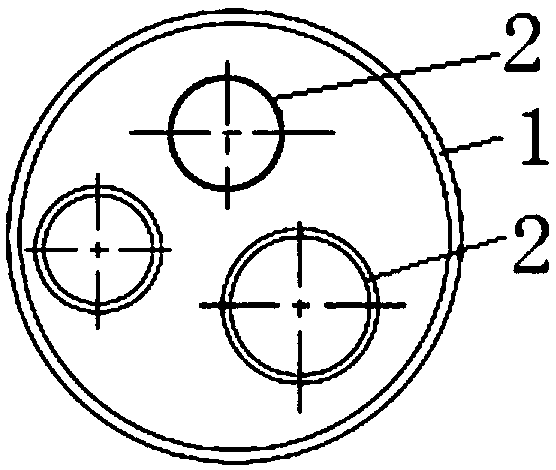

[0026] Such as Figure 1~3 As shown, the tube bundle riser structure assembly proposed by the present invention includes a plurality of outer protective tubes 1 connected in sequence, and the axes of each outer protective tube 1 are located on the same straight line, thereby forming an elongated outer protective tube section. Inside each outer protective tube 1 are provided three casings 2 with a certain interval and arranged parallel to the protective tube 1 , the outer wall of each casing 2 is connected with the inner wall of the outer protective tube 1 . Corresponding every two bushings 2 in two adjacent outer protection pipes 1 are coaxially arranged to form a plurality of pipeline passages for placing conveying hoses and / or submarine cables, while also protecting the conveying hoses and / or submarine cable.

[0027] In the above-mentioned embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com