Electrical controller for Anti-stall tools for downhole drilling assemblies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

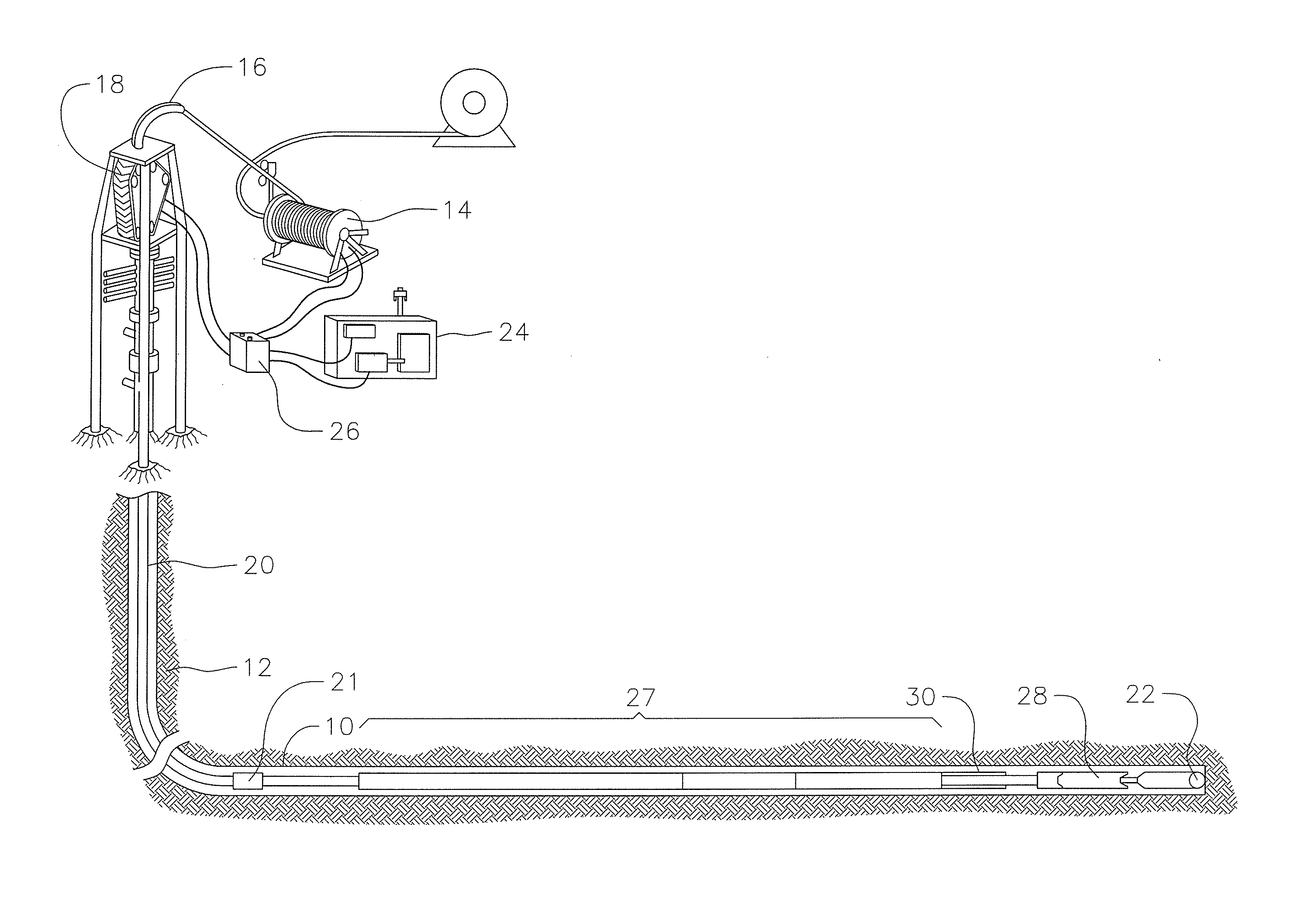

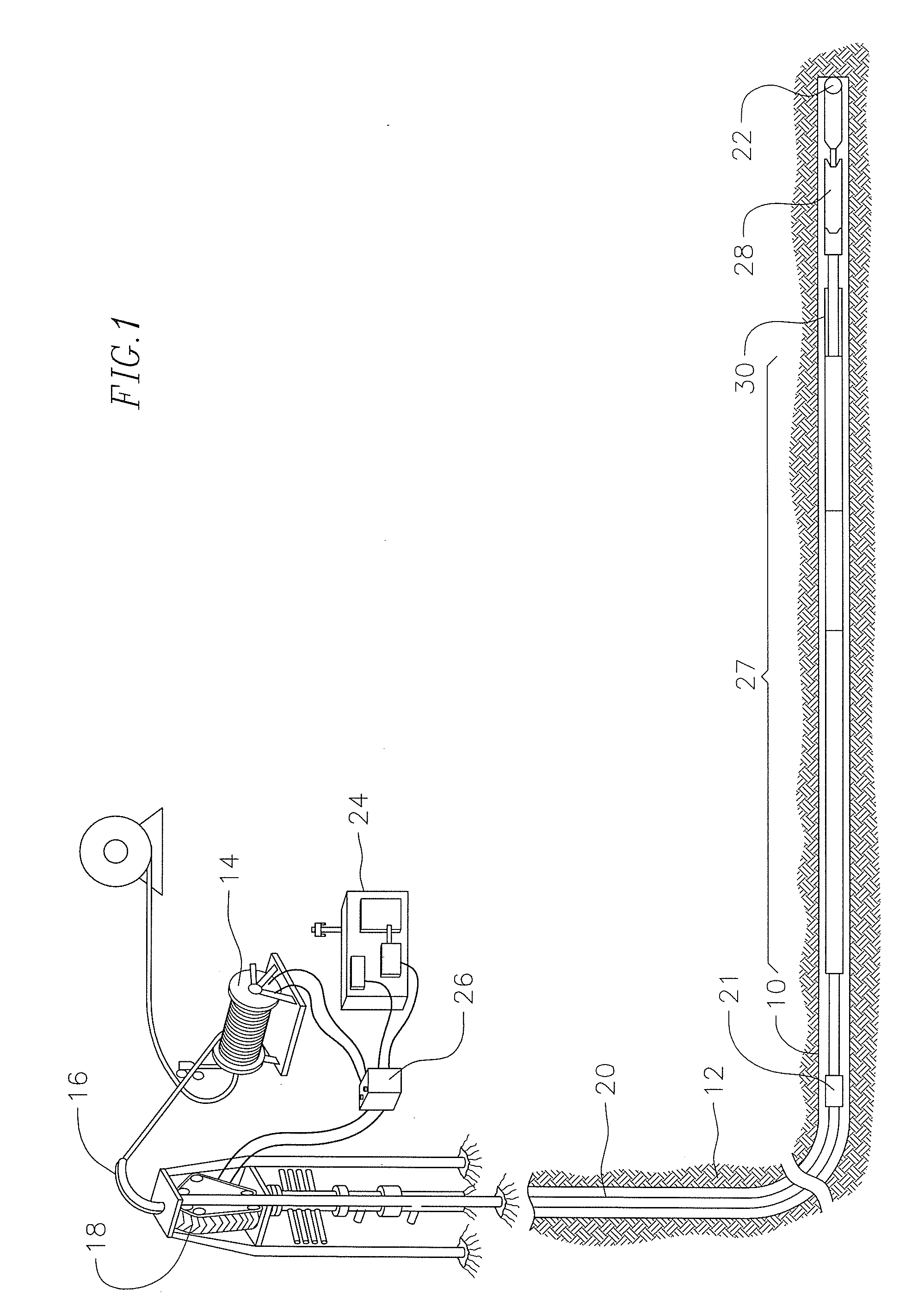

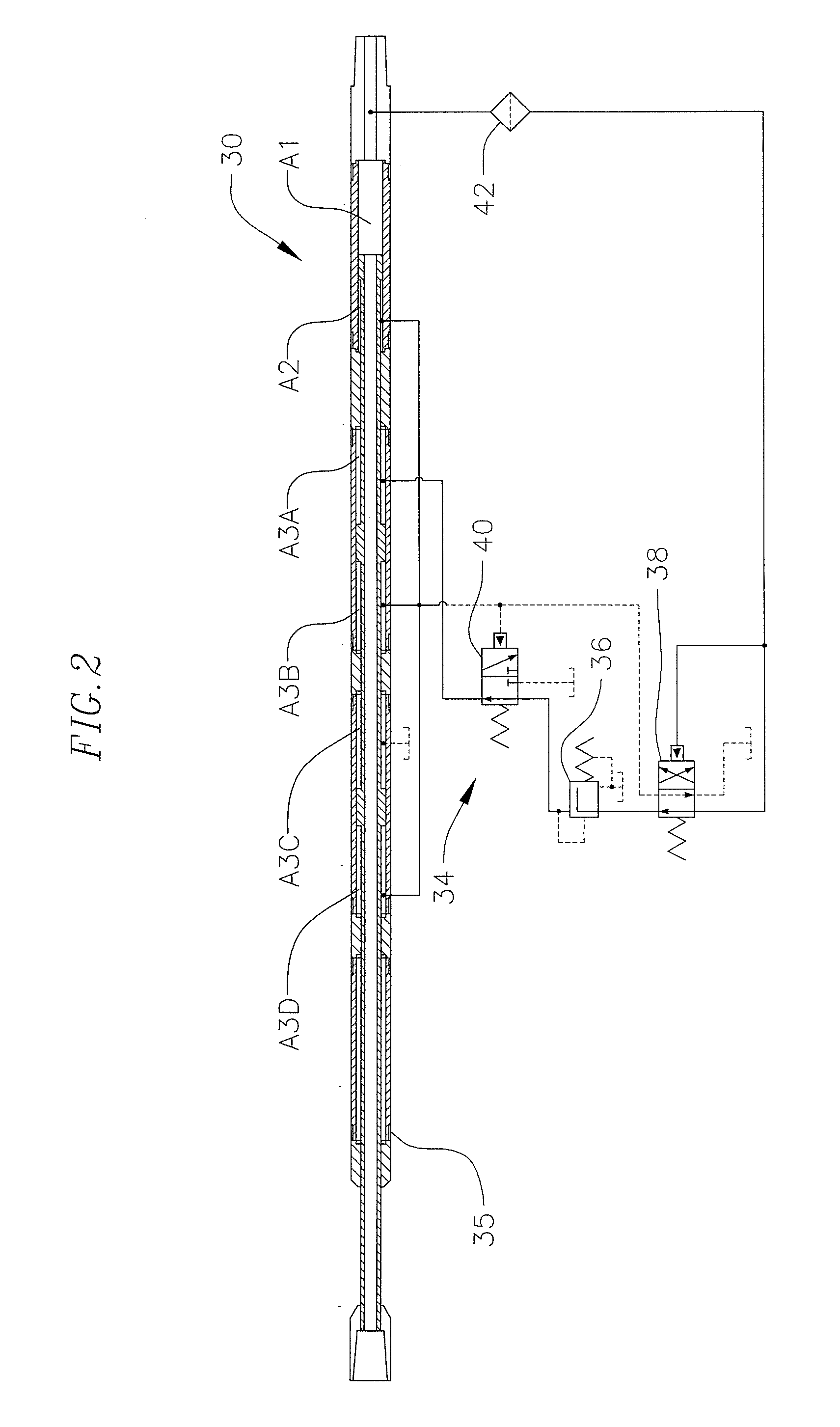

Image

Examples

example

Specifications for One Embodiment AST Illustrated in FIGS. 6-8

[0076]

DescriptionCharacteristicTool OD3.00inTool ID.75inLength - Expanded8.1ftLength - Collapsed7.4ftStroke9inMax Temp300°F.Tensile Strength50,000lbsMax Motor Torque2,000ft-lbsMax Dog Leg25° / 100ftTool Joint2⅜PAC

[0077]The design of an electrically controlled AST is flexible in that the pressure settings may be changed to fine tune the AST. Programmable pressure settings may be changed on surface or while in operation. Current available communication techniques include mud pulse telemetry, fiber optic and wireline.

[0078]If a large increase in WOB is needed, then the shaft of the AST can be replaced to allow the installation of additional pistons.

Total DownholePressure ControlMax WOB from# of PistonArea (sq. in)Valve Setting (psi)AST (lbs)14.86503,05527.96505,135311.06507,150

[0079]Features and Benefits:

The following illustrates features of an electrically controlled AST:

[0080]Active WOB: The tool will attempt reset into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com