Damping structure device capable of lowering resonance amplitude of compressor unit piping

A technology of resonance amplitude and compressor unit, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of limiting the operating frequency range of the inverter compressor, increasing the natural frequency and modal transition of the piping, and detrimental to the transportation safety of the compressor piping, and shortening the time to market. time, removing the risk of demagnetization, increasing the effect of air conditioning energy efficiency indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

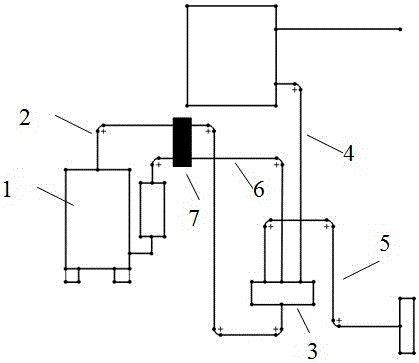

[0035] Such as figure 2 As shown, the present invention provides a damping structure device that can effectively reduce the resonance amplitude of the piping of the compressor unit, which includes a compressor 1, an exhaust pipe 2, a four-way valve 3, a valve condenser connecting pipe 4, a low pressure pipe 5, and a return pipe. Trachea 6, damping film 7. The damping film 7 is connected to the exhaust pipe 2 and the air return pipe 6. At this time, as long as the exhaust pipe 2 or the air return pipe 6 resonates to generate a large amplitude, the damping film 7 will provide a damping and vibration reduction function, effectively reducing The resonance amplitude of the exhaust pipe 2 or the air return pipe 6.

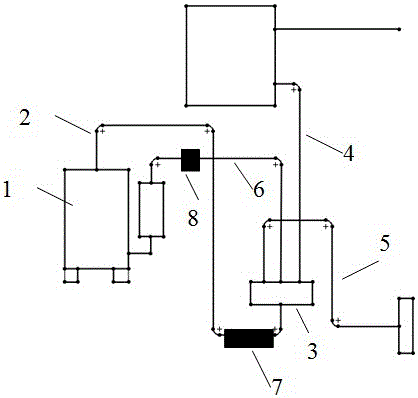

[0036] figure 1It is a schematic diagram of an embodiment of the prior art. As shown in the figure, a damping film 7 and a mass block 8 are used. The mass block 8 is functionally equivalent to the damping film 7, and is actually two damping films 7. However, the pres...

Embodiment 2

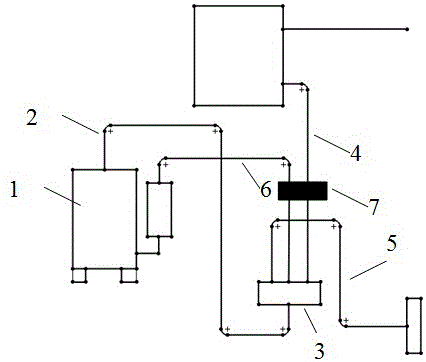

[0038] Such as image 3 As shown, the present invention provides a damping structure device that can effectively reduce the resonance amplitude of the piping of the compressor unit, including a compressor 1, an exhaust pipe 2, a four-way valve 3, a valve condenser connecting pipe 4, a low-pressure pipe 5, and a return pipe 6. Damping film7. The damping film 7 is connected to the air return pipe 6 and the valve condenser connecting pipe 4. At this time, as long as the air returning pipe 6 or the valve condenser connecting pipe 4 resonates to generate a large amplitude, the damping film 7 will provide a damping and vibration reduction function. Effectively reduce the resonance amplitude of the air return pipe 6 or the connecting pipe 4 of the valve condenser.

[0039] figure 1 It is a schematic diagram of an embodiment of the prior art. As shown in the figure, a damping film 7 and a mass block 8 are used. The mass block 8 is functionally equivalent to the damping film 7, and i...

Embodiment 3

[0041] Such as Figure 4 As shown, the present invention provides a damping structure device that can effectively reduce the resonance amplitude of the piping of the compressor unit, including a compressor 1, an exhaust pipe 2, a four-way valve 3, a valve condenser connecting pipe 4, a low-pressure pipe 5, and a return pipe 6. Damping film7. The damping film 7 is connected between the valve condenser connecting pipe 4 and the low-pressure pipe 5. At this time, as long as the low-pressure pipe 5 or the valve condenser connecting pipe 4 resonates to generate a large amplitude, the damping film 7 will provide damping reduction. The vibration function can effectively reduce the resonance amplitude of the low-pressure pipe 5 or the connecting pipe 4 of the valve condenser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com