High-temperature anti-blockage resistance ceramic block

A high-temperature anti-blocking and porcelain block technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of wear, damage, and shortened service life of the return box, achieve high wear resistance, solve damage, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

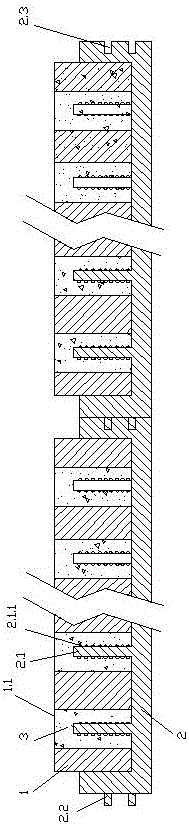

[0009] Example 1: A high-temperature anti-blocking and resistant porcelain block, including a rectangular ceramic block 1 with a thickness of 18 mm, a metal shell 2 with a thickness of 4 mm, and the rectangular ceramic block 1 is embedded in the metal shell 2. The diameter of the surface of the rectangular ceramic block 1 is The through hole 1.1 is 22mm~25mm. The inner surface of the metal shell 2 corresponds to the through hole 1.1 on the surface of the rectangular ceramic block 1. There is a boss 2.1 with a diameter of 8~10mm, and the height of the boss 2.1 is less than 18mm. Convex balls 2.1.1 with a diameter of 2 mm are arranged at intervals on the side walls of the convex posts 2.1. The wear-resistant castable 3 is poured into the through hole 1.1, and the outer surface of the side wall of the metal shell 2 is provided with a strip-shaped bump 2.2 for matching with the adjacent metal shell 2 and a strip-shaped groove 2.3 matched with the strip-shaped bump 2.2 , the height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com