Reverse blowing deicing-type water energy recycle cooling tower

A technology of cooling towers and water energy, applied in the field of cooling towers, can solve the problems of inability to reverse and solve the problem of ice melting at the air inlet, and achieve the effect of ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

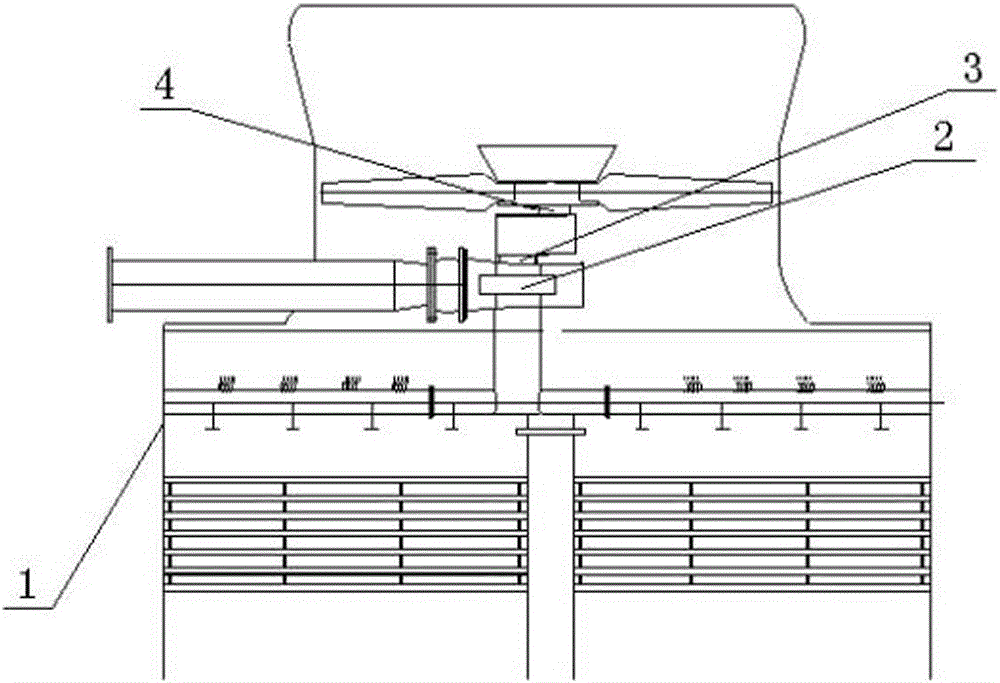

[0011] See figure 1 , the backblowing ice type water energy recovery cooling tower, including a cooling tower body 1, a water turbine is arranged in the tower body 1, and the water turbine includes a water wheel 2 and a speed reducer connected to the water wheel 2;

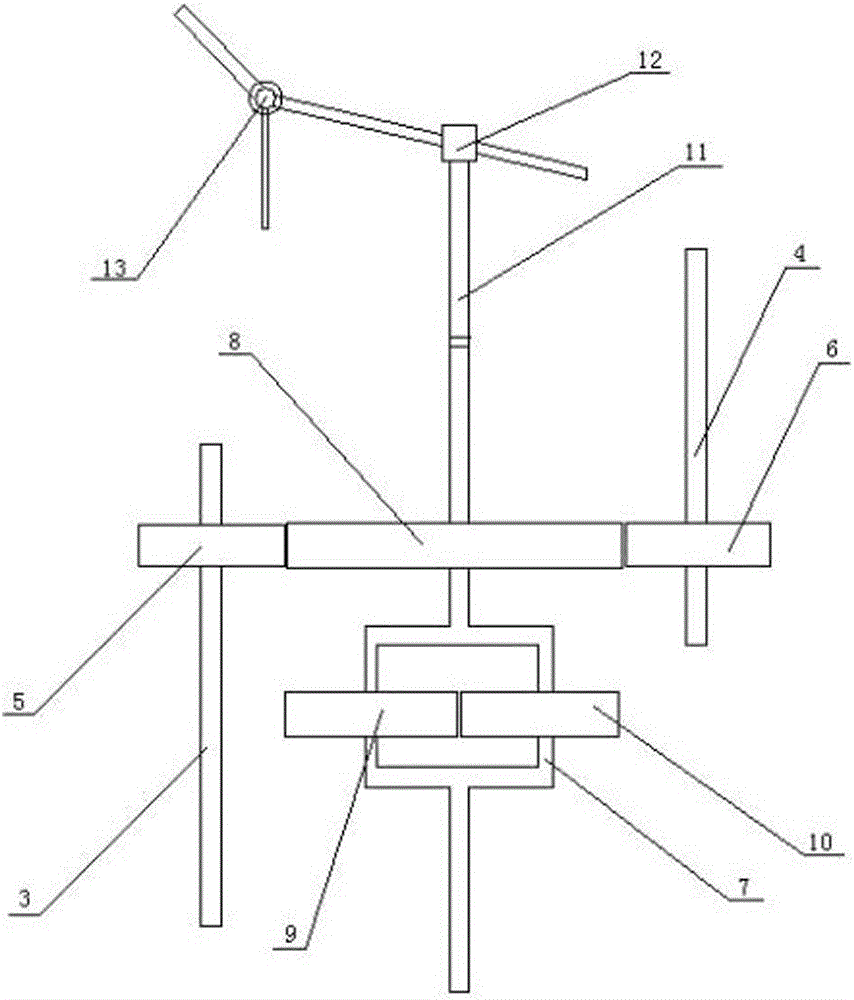

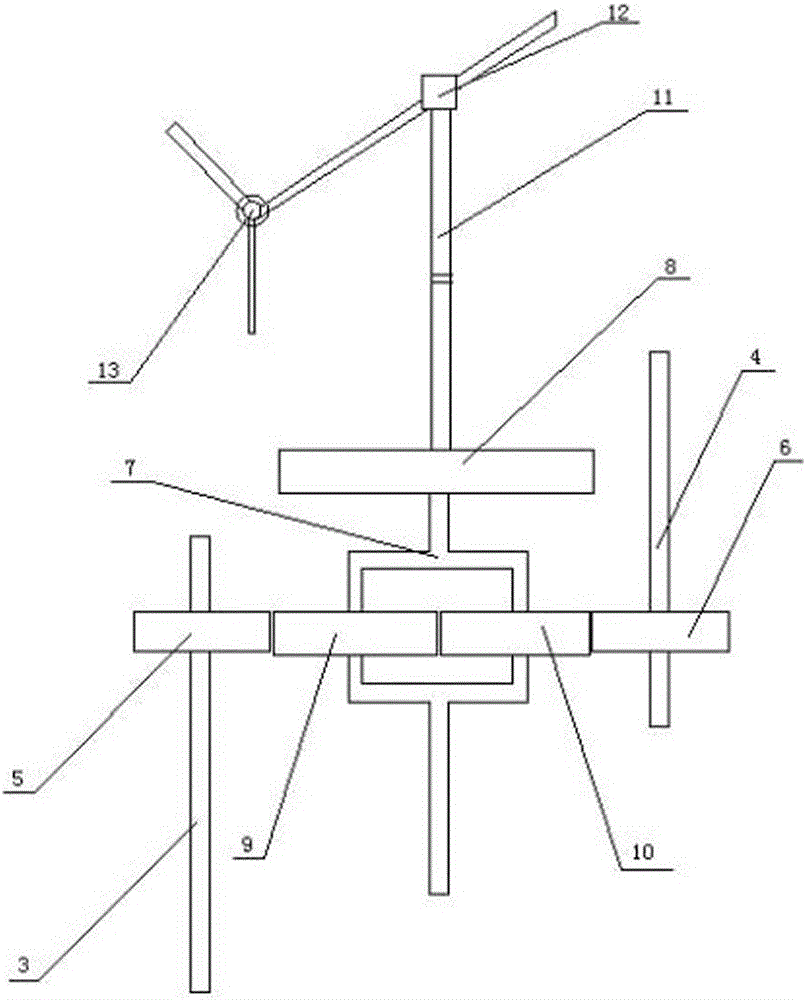

[0012] See figure 2 , image 3 The reducer includes an input shaft 3 with an input gear 5 connected to the water wheel 2 and an output shaft 4 with an output gear 6 connected to the input shaft 3, and a gear frame is arranged between the input shaft 3 and the output shaft 4 7. There are two sets of parallel transmission gear sets on the gear frame 7, and a gear frame lifting device is provided on the top of the gear frame 7. One set of transmission gear sets includes the first transmission gear 8, and the other set of transmission gear sets includes the intermeshed The second transmission gear 9 and the third transmission gear 10, the gear frame hoisting device includes a vertical pull rod 11 connected to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com