Method of three-coordinate machine measuring free-form curve

A three-coordinate machine and free technology, applied in the field of measurement, can solve the problems that the profile does not have geometric features, cannot realize the correct measurement of free curves, and cannot guarantee that the probe is perpendicular to the profile point, and achieves simple operation and obvious effect , The effect of the simplified measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Measure the curved surface of a free curve sample of a test blade, and its design drawings require that the tolerance of the coordinates of the curve points be ±0.005mm. The measurement steps are as follows:

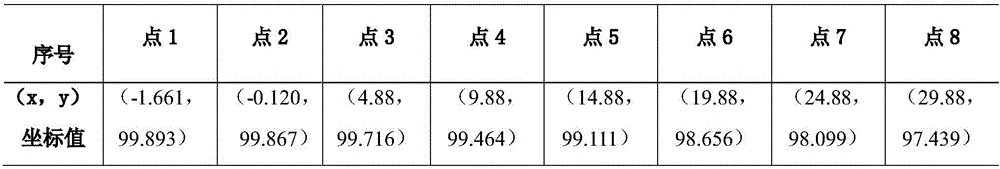

[0025] (1) Record the coordinate value points of all continuous points on the curved surface of the free curve template:

[0026]

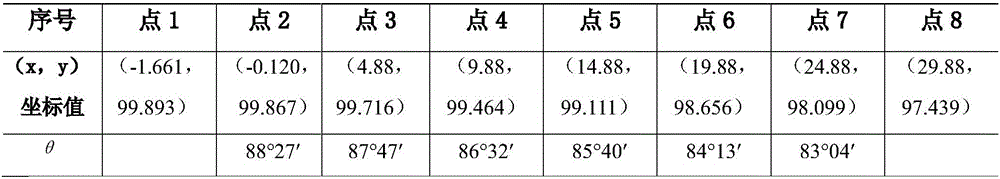

[0027] (2) Select the point coordinates of the non-end points to be measured in turn, and the coordinates of two adjacent points, and use the coordinate values of the two adjacent points to calculate the normal angle θ at the midpoint of the two adjacent coordinate points:

[0028]

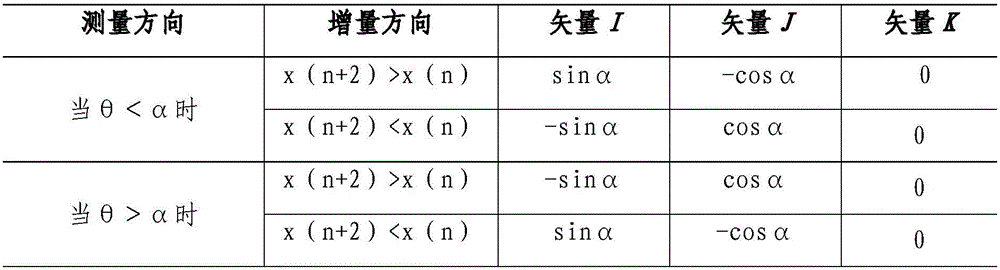

[0029] (3) According to the result of step (2) and the coordinate values of two adjacent points, define the point to be measured (x n ,y n ), the normal vector (I, J, K) at

[0030]

[0031] The result is as follows:

[0032]

[0033] (4) Input the coordinate value and direction vector of the measuring point into the measuring machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com