Self-cleaning fluid metering device

A metering device and self-cleaning technology, applied in the field of metering, can solve the problems of increasing the contact wear of the remaining working surface, limiting the life of the metering device, etc., to achieve the effect of ensuring self-cleaning, avoiding metering errors, and preventing the accumulation of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

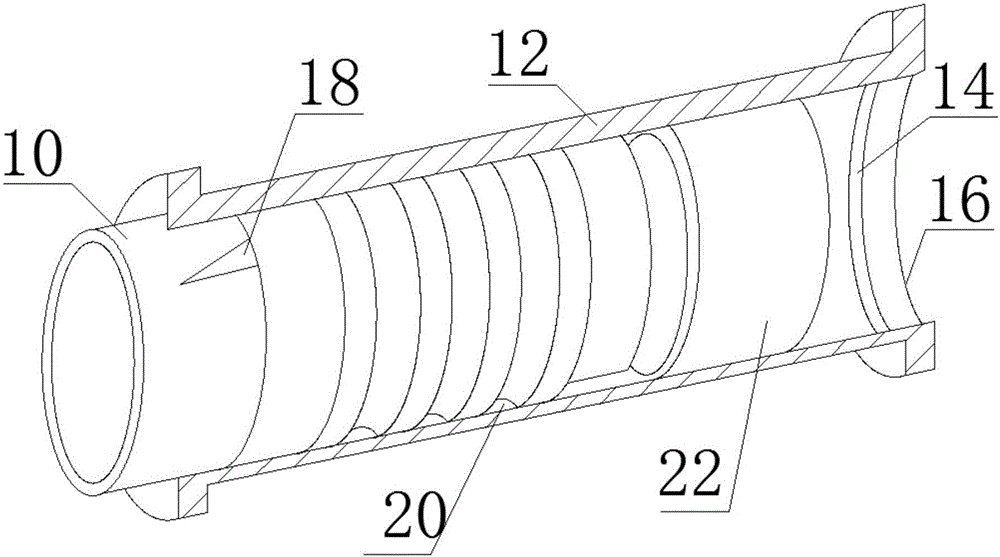

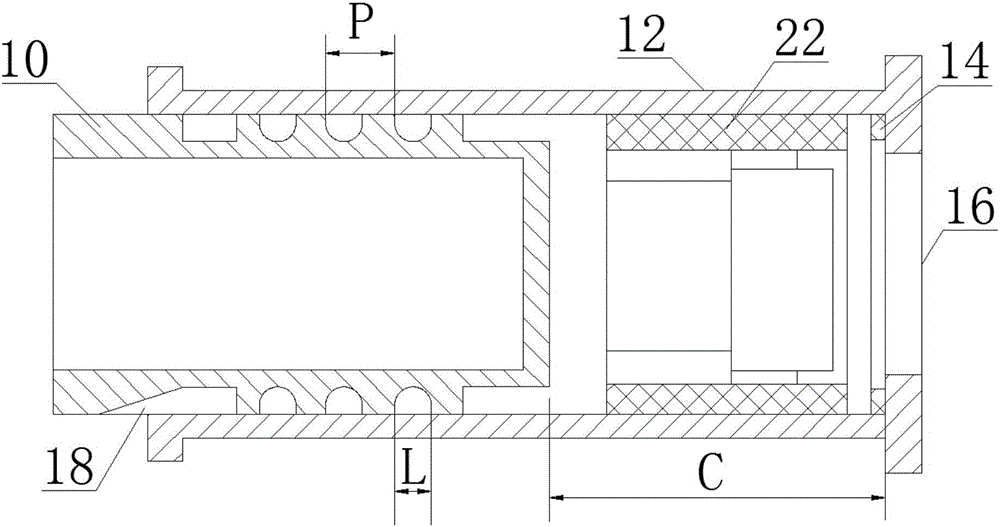

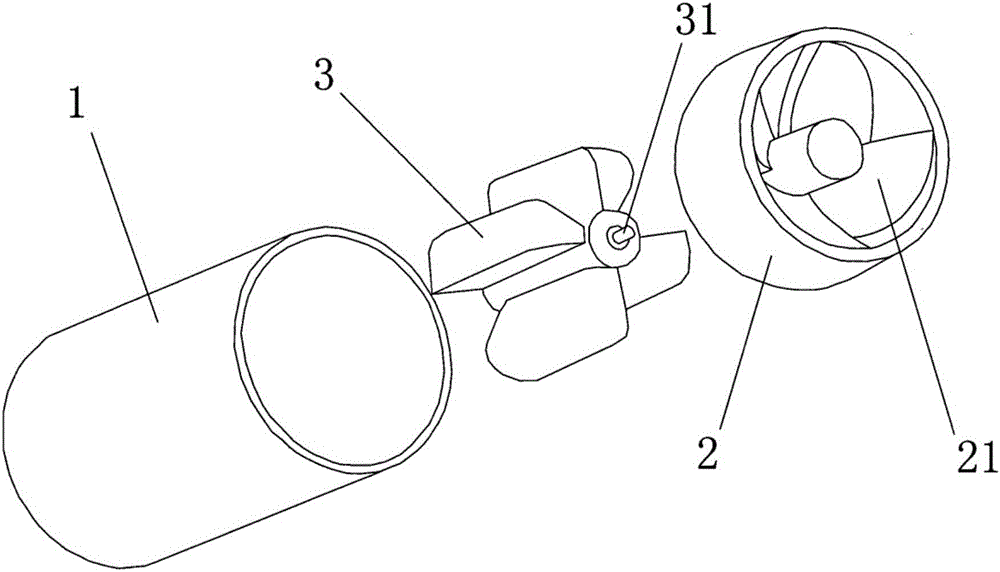

[0023] Such as figure 1 , figure 2 , image 3 As shown, a self-cleaning fluid metering device is used for metering fluid from a supply source to a device using the fluid, comprising a sleeve 12 and a metering valve 10 capable of sliding through a stroke C in the sleeve 12, the The sleeve 12 includes an inlet hole 16 for receiving fluid from the supply source, the metering valve 10 includes a hole for discharging the fluid to the device using the fluid, and the hole for discharging the fluid includes a drainage slot 18, which may be located outside said sleeve 12;

[0024] The self-cleaning fluid metering device also includes means 20 for directing fluid during movement of the metering valve 10 within the sleeve ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap