Method for computing air impermeability of gas storage cavity

A calculation method and technology for gas storage chambers, which are applied in liquid/vacuum measurement for liquid tightness, fluid tightness testing, and testing of machine/structural components, etc., and can solve problems that have not been published yet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The airtightness of the gas storage chamber is one of the important parameters to evaluate the compressed air energy storage system, which directly affects the operating efficiency of the compressed air energy storage power station.

[0039] The purpose of the present invention is to provide a method for calculating the gas leakage of a gas storage chamber for compressed air energy storage, so as to provide the gas leakage under different lining permeability, and to ensure the gas storage by controlling the permeability of the lining. The airtightness of the chamber.

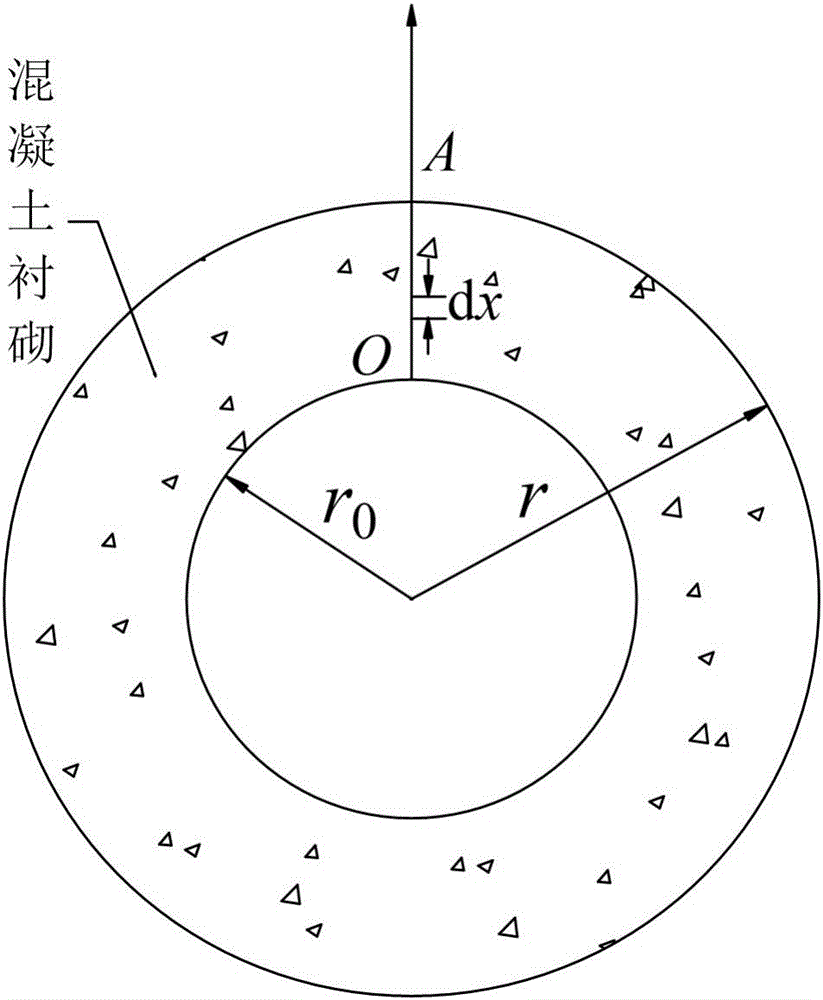

[0040] Such as figure 1 As shown, the gas storage cavern of the present invention is a spherical cavern, and the inner wall of the cavern is lined with a circle of concrete, and the concrete medium is uniform, that is, the pores in the concrete are also uniformly distributed, so it can be taken in a certain direction Analysis of air seepage.

[0041] Such as figure 1 As shown, assume that the radius of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com