Concrete temperature stress testing machine with temperature deformation self-compensation function

A concrete temperature and stress test technology, applied in the direction of strength characteristics, material inspection products, measuring devices, etc., can solve problems such as errors and large temperature deformation errors of concrete, and achieve the effects of accurate results and high temperature control efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

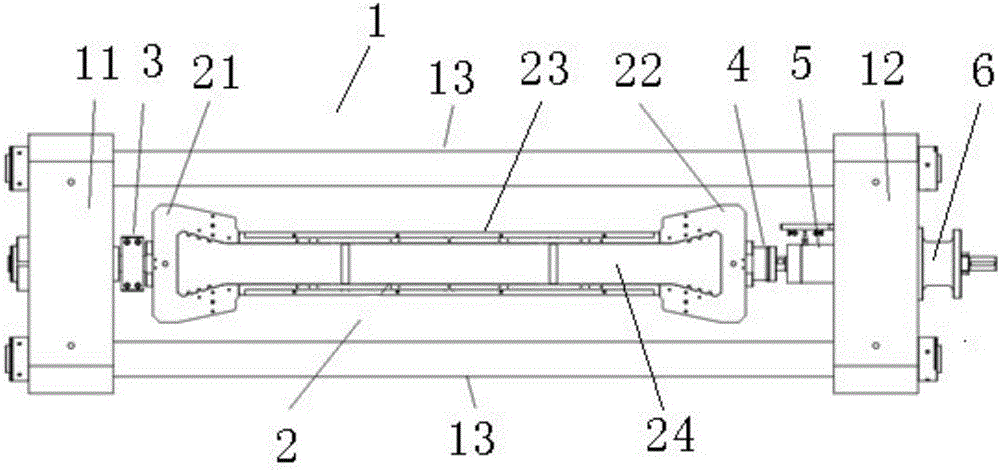

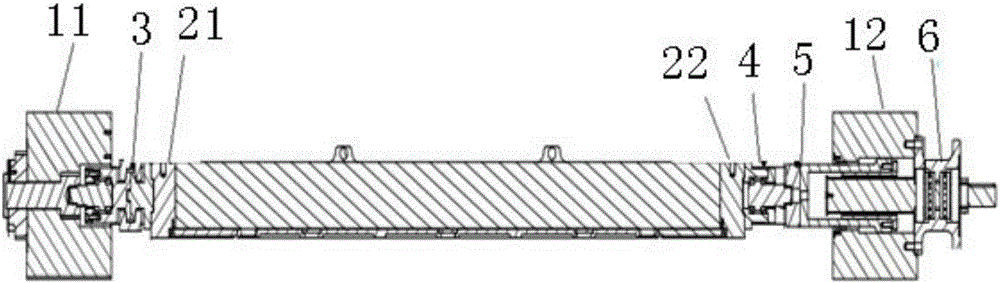

[0019] see figure 1 , a concrete temperature stress testing machine with temperature deformation self-compensation function provided by an embodiment of the present invention, comprising:

[0020] The main body 1 of the testing machine is composed of a left fixed end 11, a right fixed end 12, and a pair of light rods connected between the left fixed end 11 and the right fixed end 12;

[0021] The concrete specimen mold 2 is made of a fixed chuck 21, a movable chuck 22, a side template 23 and a bottom template 24 connected between the fixed chuck 21 and the movable chuck 22;

[0022] Wherein, the left fixed end 11 is connected with the fixed chuck 21 through the fixed end universal joint 3, the right fixed end 12 is connected with the movable chuck 22 through the moving end universal joint 4, and the outer side of the right fixed end 12 is connected with a The servo motor 6 is connected to the load sensor 5 through bolts, and the load sensor 5 is connected to the mobile univer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com