Device and method for detecting instability of steel-structure pressing rod

A steel structure and pressure rod technology, applied in the field of construction engineering, can solve the problems that the detection device cannot walk freely, and cannot detect the instability of the steel structure axial compression rod, so as to achieve strong replaceability, ensure universality, and good quality. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

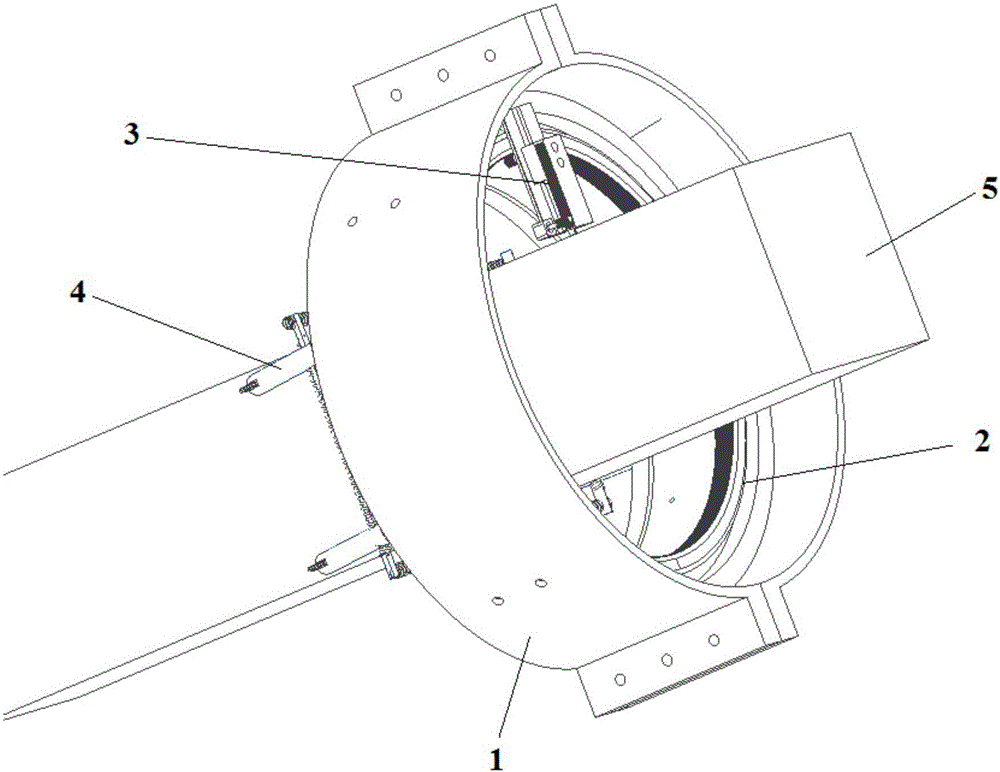

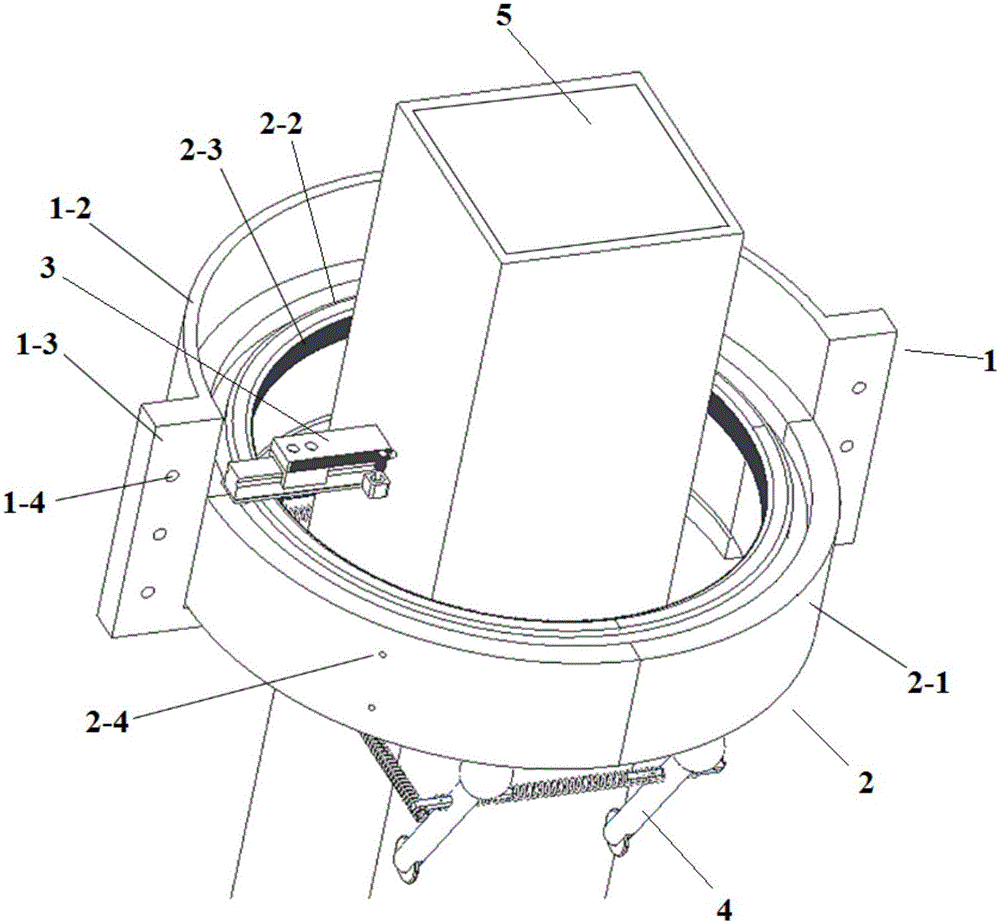

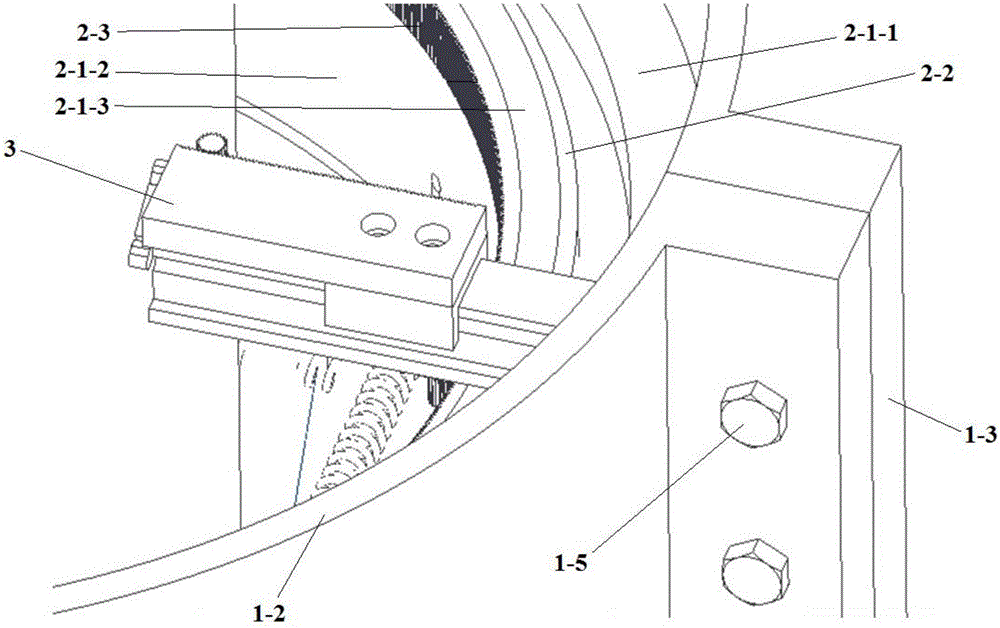

[0057] Comply with the above technical solutions, such as Figure 1 to Figure 9 As shown, this embodiment provides a device for detecting the instability of a steel structure pressure bar, including a magnetically shielded outer support ring 1, an inner support ring 2, a retractable magnetic memory detection pen 3 and a power walking mechanism 4, and an inner support ring 2 Installed in the magnetic shielding outer bracket ring 1, the power traveling mechanism 4 is installed on the outer wall of the backstop ring 1-1 at the rear end of the magnetic shielding outer bracket 1, and the retractable magnetic memory detection pen 3 is installed in the inner bracket ring 2, steel The structural pressure rod 5 passes through the inner bracket ring 2, the power traveling mechanism 4 can walk on the steel structure pressure rod 5, and the retractable magnetic memory detection pen 3 is used to detect the steel structure pressure rod 5;

[0058] The front end of the magnetic shielding out...

Embodiment 2

[0073] This embodiment provides a method for detecting the instability of a steel structure pressure bar. The method uses the device for detecting the instability of a steel structure pressure bar in Example 1. The method specifically includes the following steps:

[0074] Step 1, the retractable magnetic memory detection pen 3 is installed on the inner support ring 2, that is, the circular guide block 3-3 is embedded in the circumferential guide groove 2-2 of the inner support plate 2-1, and Make the ring power gear 3-5 mesh with the ring meshing track 2-3, install the inner bracket plate 2-1 of the inner bracket ring 2 in the outer bracket plate 1-2 of the magnetic shield outer bracket ring 1, and install the inner bracket The inner reserved hole 2-4 on the plate 2-1 is aligned with the outer reserved hole 1-6 on the outer support plate 1-2, and the inner support plate 2-1 and the outer support plate are connected by fixing bolts 1-5 1-2 connection, then butt-wrap the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com