Automatic constant temperature insulating oil dielectric strength tester

A technology of dielectric strength and insulating oil, which is applied in the field of automatic constant temperature insulating oil dielectric strength tester, which can solve the problems of inability to adjust or control the sample temperature, inaccurate test results, and low test results, so as to shorten the balance time , easy to use, improve the effect of heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

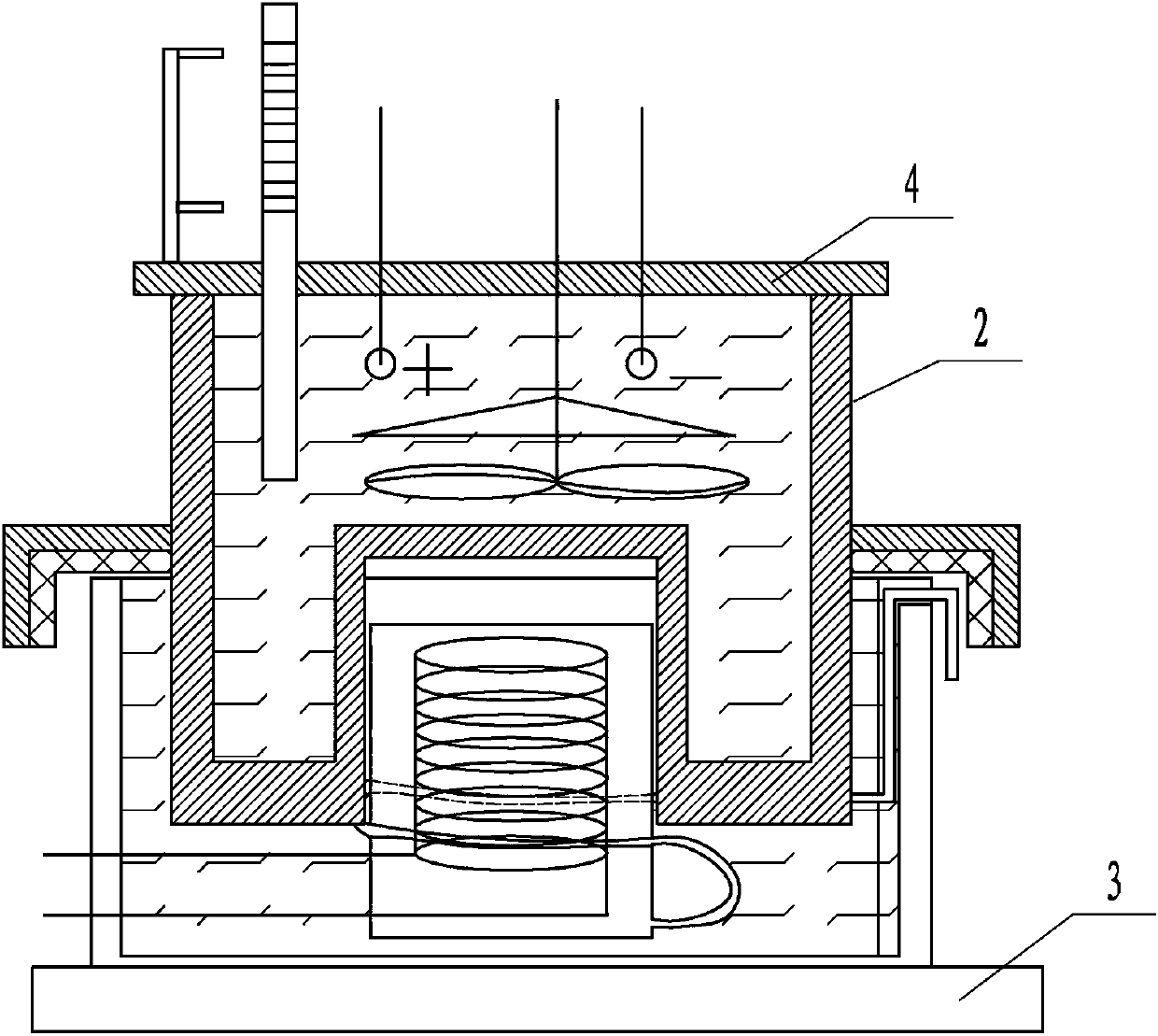

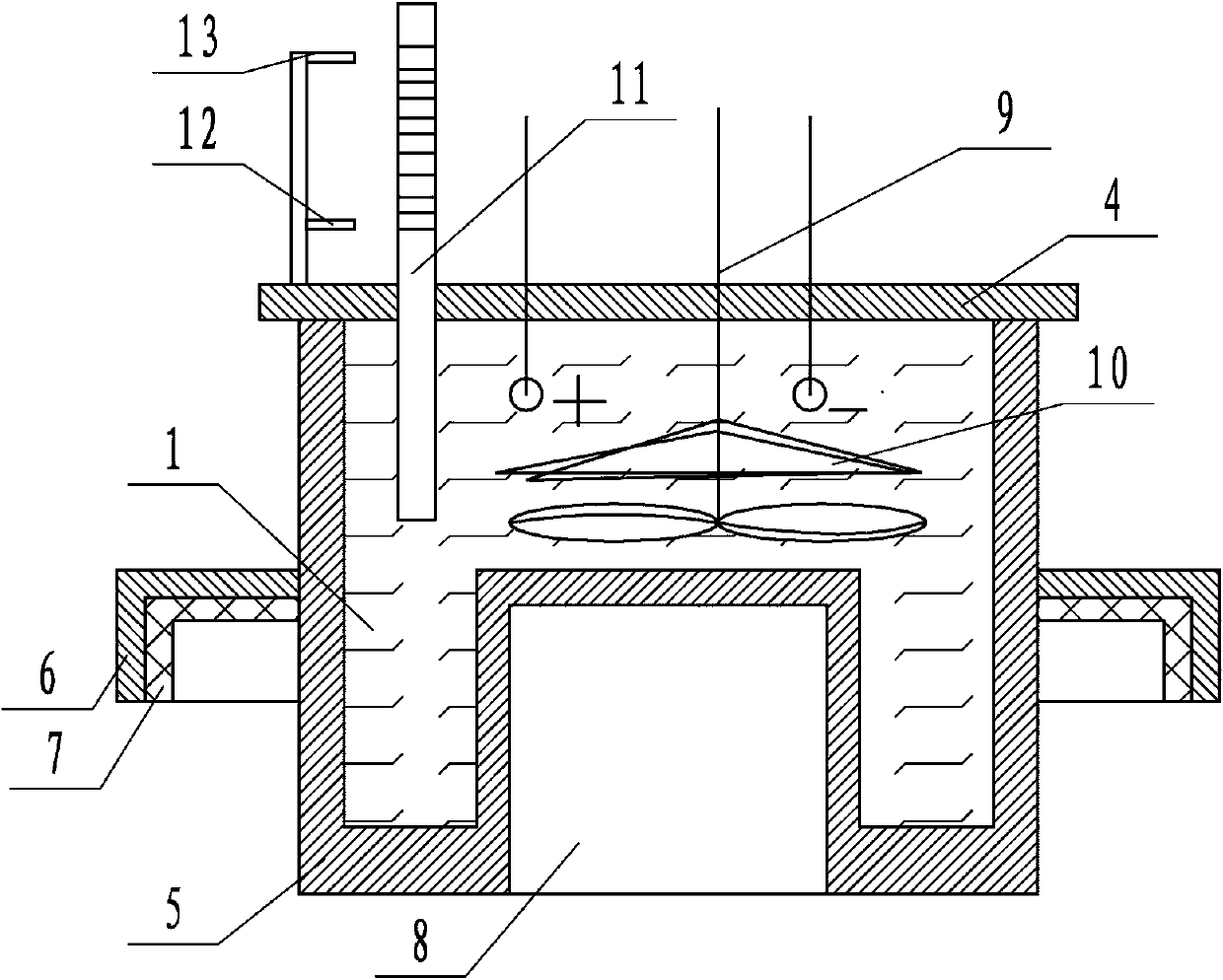

[0034] Such as Figure 1-4 As shown, the present invention includes a container device 2 for holding insulating oil 1, a temperature control heating device 3 arranged under the container device 2, and an electric control system;

[0035] The container device 2 includes a glass vessel 5 for containing the insulating oil 1 and a central concave platform 8 arranged at the bottom of the glass vessel 5 and protruding upward;

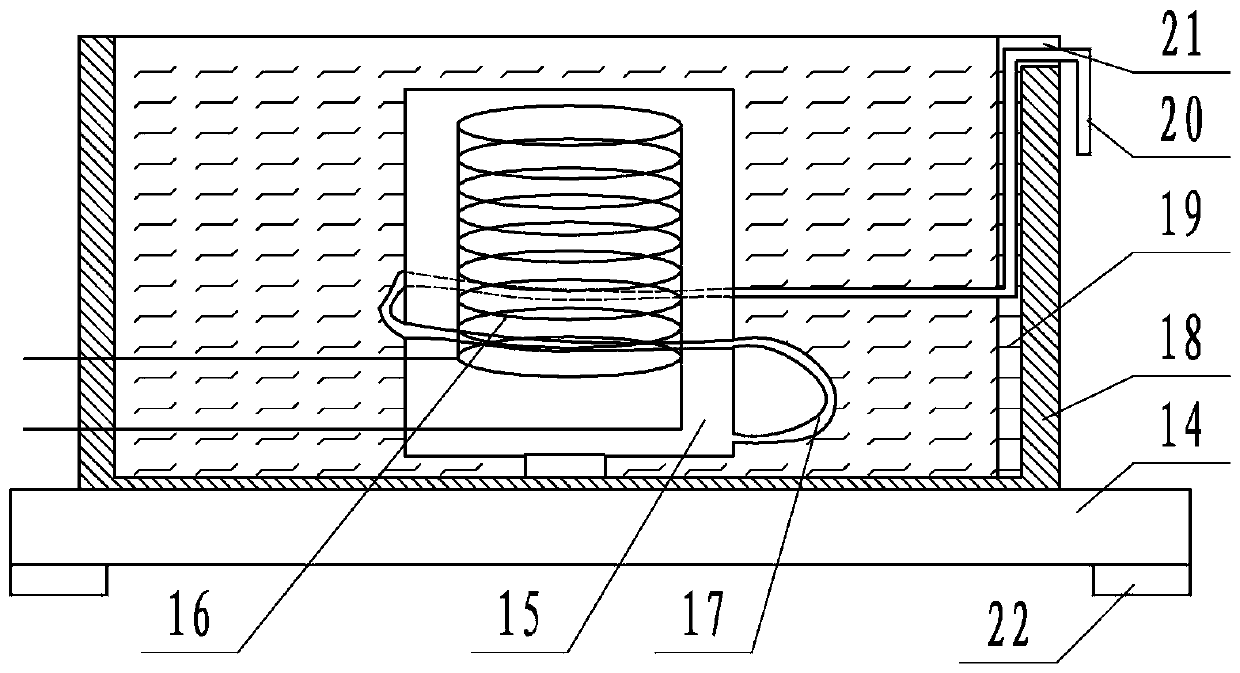

[0036] The temperature control heating device 3 comprises an insulating oil-proof shell 18 for placing glassware 5, a base 14 arranged below the insulating oil-proof shell 18, a hollow oil-proof insulating box 15 in the insulating oil-proof shell 18 and a set The heating coil 16 in the hollow oil-proof insulating box 15; the hollow oil-proof insulating box 15 is a material with good thermal conductivity, such as metal or glass; a test electrode is arranged in the glass vessel 5;

[0037] The electric control system includes a heating module 24, an upper limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com