a transmission grating

A transmission grating and light-transmitting film technology, applied in the optical field, can solve problems such as inaccurate analysis results, reduced spectral accuracy, and errors, and achieve the effects of improving spectral accuracy, improving signal-to-noise ratio, and eliminating losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

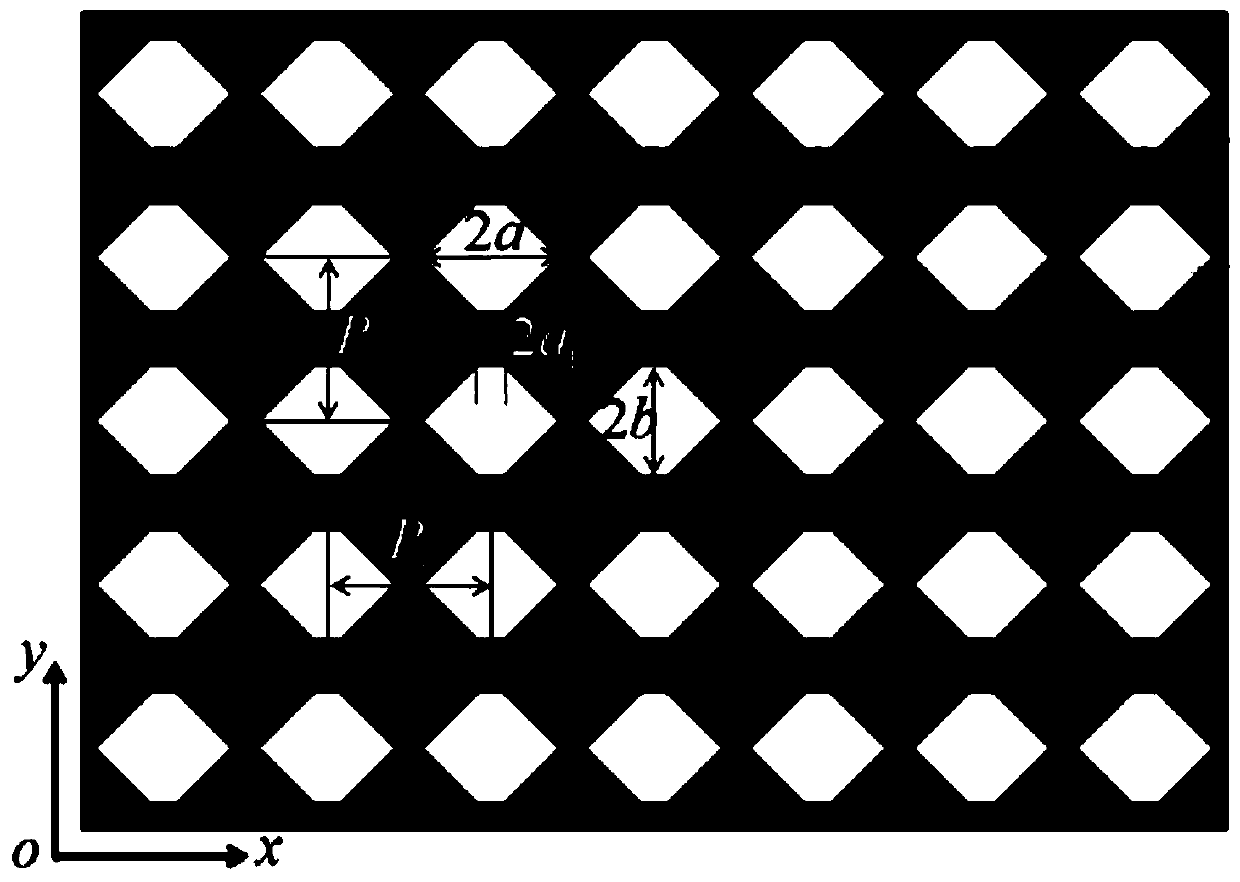

[0029] This embodiment provides a transmission grating, such as figure 1 As shown, the transmission grating includes: an opaque film and N transparent symmetrical polygonal holes; wherein, the N transparent symmetrical polygonal holes are distributed in an oblique grid on the opaque film, and the There is a preset ratio between the period of the rhombic grid and the size of the symmetrical polygonal hole. Wherein, the rhombic lattice specifically includes: square lattice, rectangular lattice, triangular lattice, rectangular lattice with a heart and common oblique lattice. In this embodiment, it is preferably a rectangular grid.

[0030] Specifically, the rectangular grid distribution is specifically: the symmetry center of any symmetrical polygonal hole is connected with the symmetry centers of three adjacent symmetrical polygons to form a rectangle. The period of the rectangular grid along the x-axis direction is P x , that is, the distance between the centers of symmetry ...

Embodiment 2

[0045] Compared with Embodiment 1, this embodiment also provides a transmission grating, which includes: an opaque film and N transparent symmetrical polygonal holes; wherein, the N transparent symmetrical polygonal holes are in the non-transparent The light-transmitting film is distributed with rhombic grids, and there is a preset ratio between the period of the rhomboid grids and the size of the symmetrical polygonal holes. Wherein, the rhombic lattice specifically includes: square lattice, rectangular lattice, triangular lattice, rectangular lattice with a heart and common oblique lattice. In this embodiment, it is preferably a rectangular grid.

[0046] Specifically, the rectangular grid distribution is specifically: the symmetry center of any symmetrical polygonal hole is connected with the symmetry centers of three adjacent symmetrical polygons to form a rectangle. The period of the rectangular grid along the x-axis direction is P x , that is, the distance between the ...

Embodiment 3

[0065] Compared with Embodiment 2, this embodiment also provides a transmission grating, which includes: an opaque film and N transparent symmetrical polygonal holes; The light-transmitting film is distributed with rhombic grids, and there is a preset ratio between the period of the rhomboid grids and the size of the symmetrical polygonal holes. Wherein, the rhombic lattice specifically includes: square lattice, rectangular lattice, triangular lattice, rectangular lattice with a heart and common oblique lattice. In this embodiment, it is preferably a rectangular grid.

[0066] Specifically, the rectangular grid distribution is specifically: the symmetry center of any symmetrical polygonal hole is connected with the symmetry centers of three adjacent symmetrical polygons to form a rectangle. The period of the rectangular grid along the x-axis direction is P x , that is, the distance between the centers of symmetry of adjacent symmetrical polygonal holes along the x-axis direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com