A thermal imager lens protection device for protecting composite material chips

A protection device and composite material technology, applied in instruments, optical filters for photography, cameras, etc., can solve problems such as inability to protect, and achieve the effect of universality and chip protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

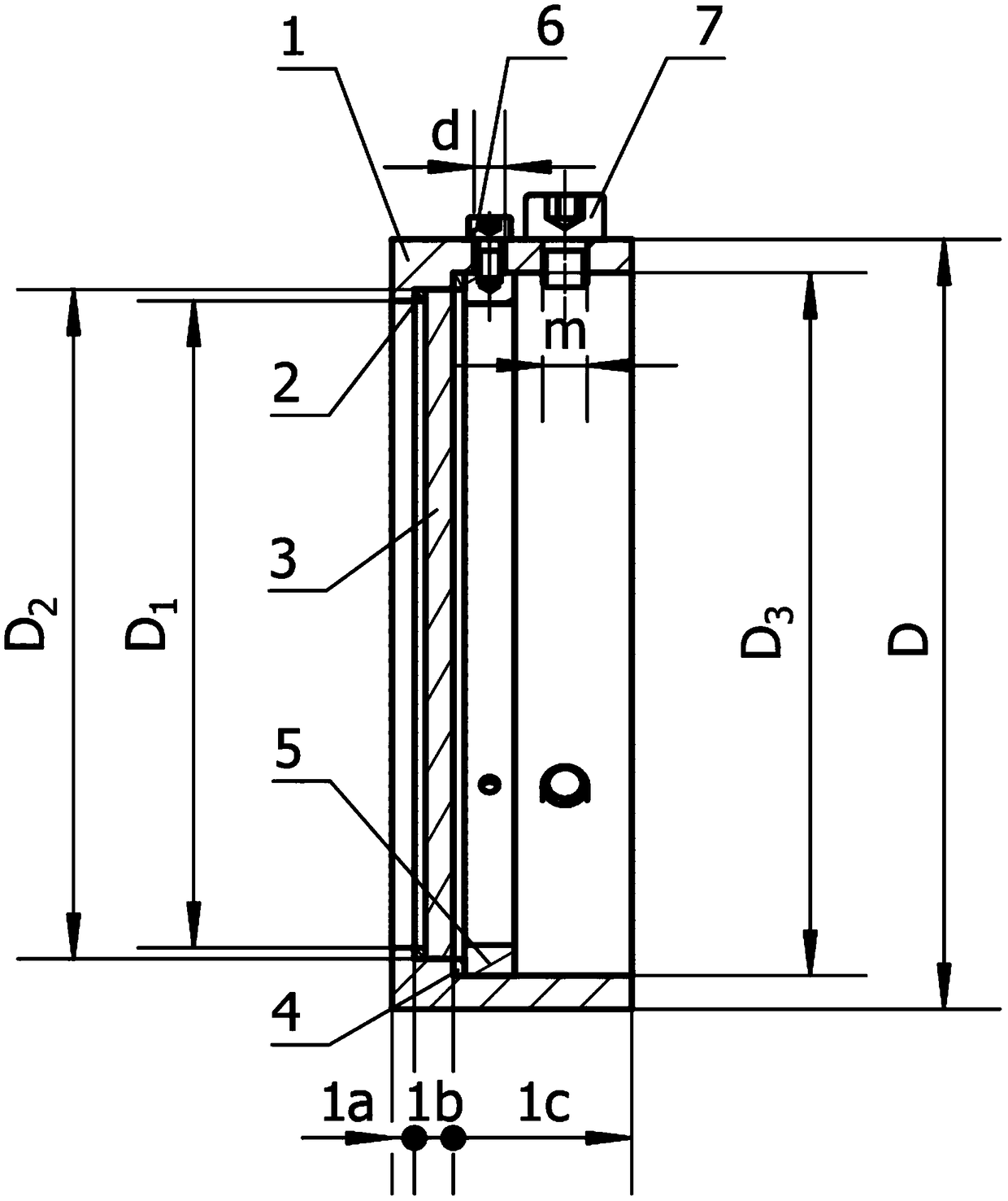

[0011] figure 1 It is a cross-sectional view of the assembly of the thermal imager lens protection device of the present invention. When in use, the thermal imager lens protection device is installed on the front end of the thermal imager lens to protect the lens and realize safe work when cutting composite materials. The size of the thermal imager lens protection device can be adjusted accordingly according to the lens size of the thermal imager, and the invention has universal applicability.

[0012] The device includes a housing 1, small and large nylon gaskets 2, 4, calcium fluoride wafer 3 and positioning gasket 5, screws 6, and connecting screws 7; the small nylon gasket 2 is installed on the second stepped ring 1b of the housing 1 At the edge of the first stepped ring 1a, the calcium fluoride wafer 3 is placed in the second stepped ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com