A control method for reducing the cost consumption of alloy steel per ton

A technology per ton of steel and alloy, applied in the control field of reducing the cost of alloy per ton of steel, can solve the problem of not minimizing the cost of alloy per ton of steel, reduce labor intensity, optimize the alloy ratio, and achieve intelligent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A control method for reducing cost consumption per ton of alloy steel, the control method comprising the following steps:

[0079] 1) The smelting steel type Q345B belongs to the ordinary carbon steel series. The steel composition target value is: Si: 0.25%, Mn: 1.20%, of which Si recovery rate is 80%, Mn recovery rate is 90%, and carbon recovery rate is 90%;

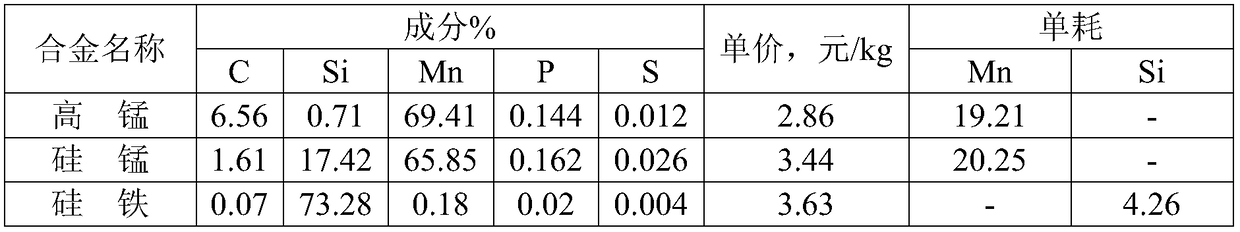

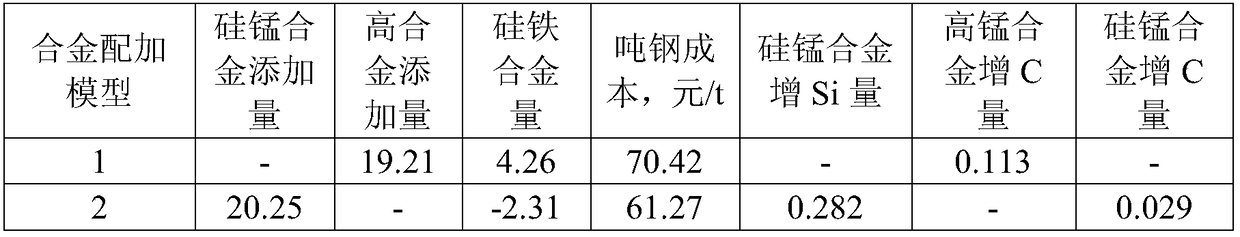

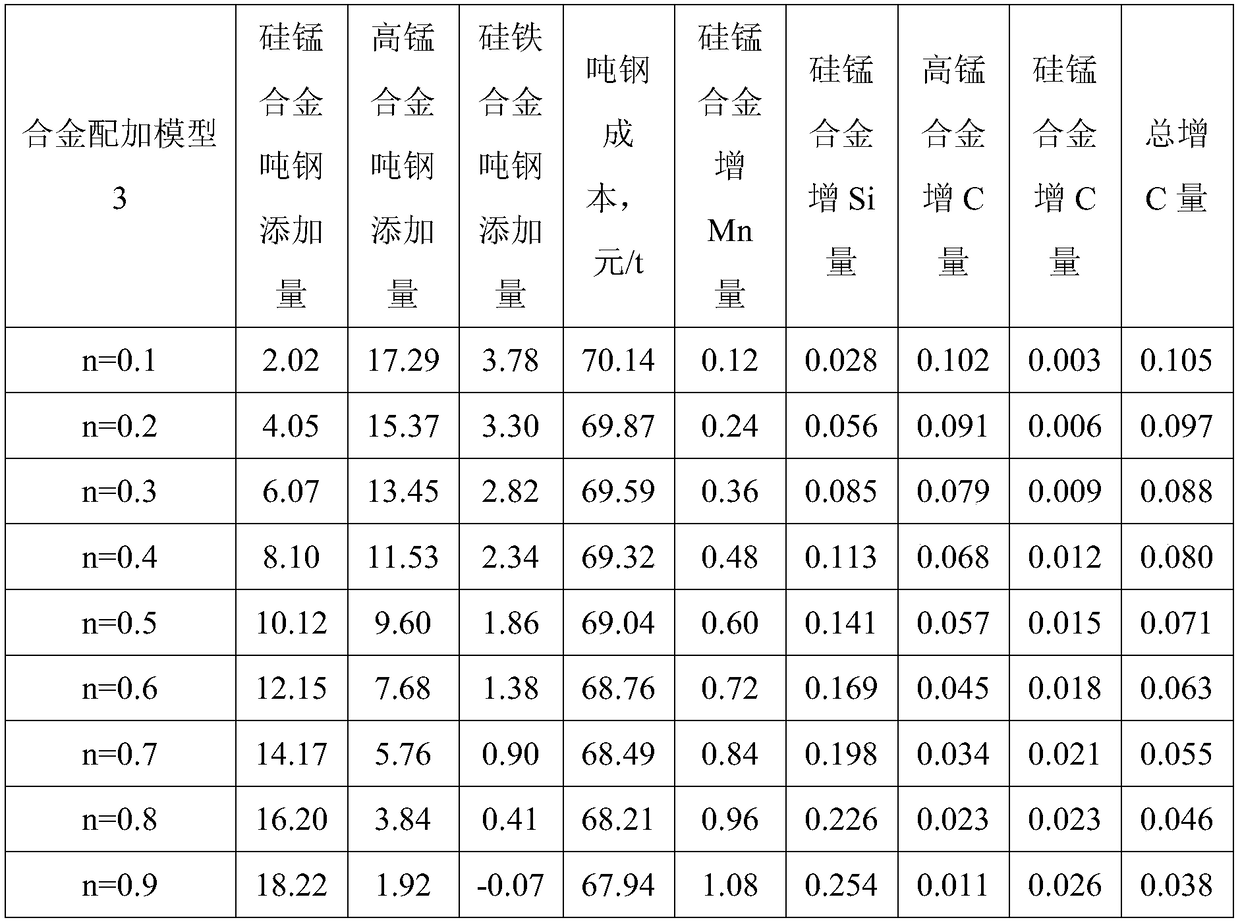

[0080] According to the target value of steel component elements, the recovery rate of component elements and the content value of alloy component elements, the standard consumption of alloy per ton of steel is calculated according to the following formula, and the results are shown in Table 1;

[0081] Standard consumption of alloy per ton of steel = target value of steel component elements × 1000 ÷ alloy component element value ÷ component element recovery rate, where the component elements are silicon and manganese, and the alloys are high-manganese alloys, medium-manganese alloys, silicon-manganese alloys, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com