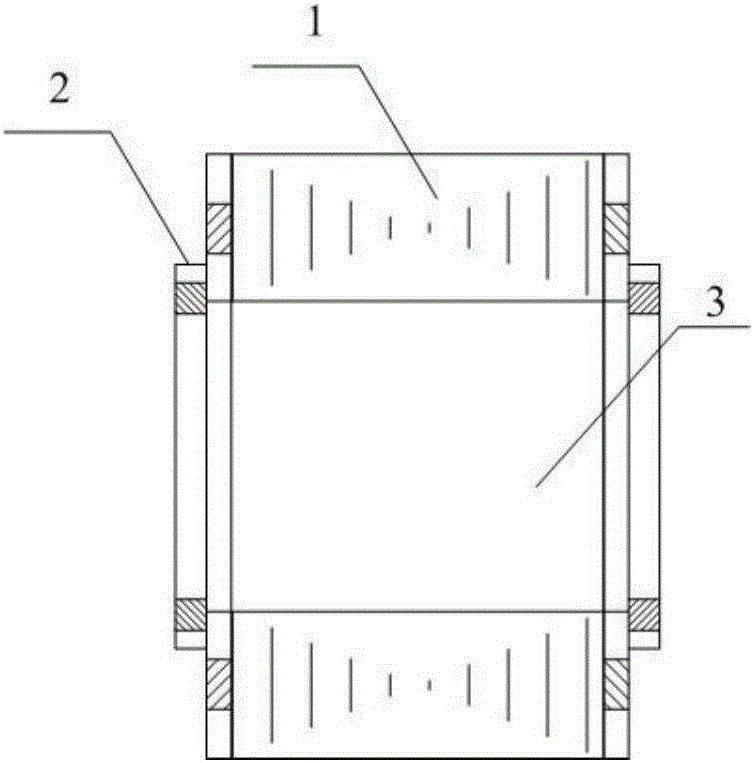

Self-adaptive dynamic balance structure of motor and adjusting method thereof

An adaptive, motor shaft technology, applied in the direction of electric components, magnetic circuit shape/style/structure, electrical components, etc., can solve the problems of increasing the weight of the motor body, falling off, etc., and achieve the effect of reducing the number of adjustments and covering a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

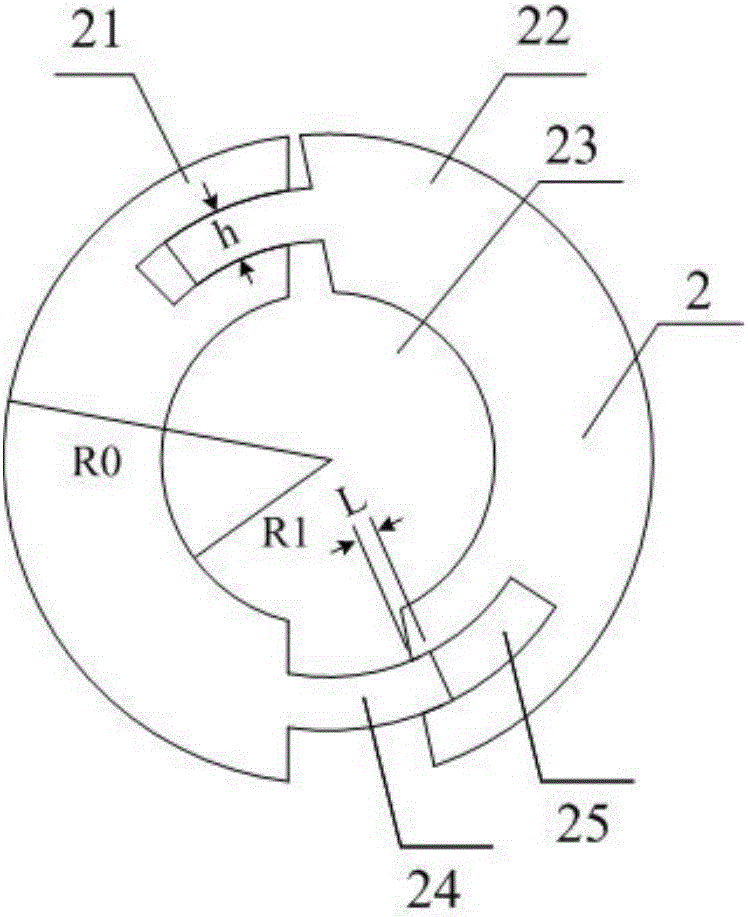

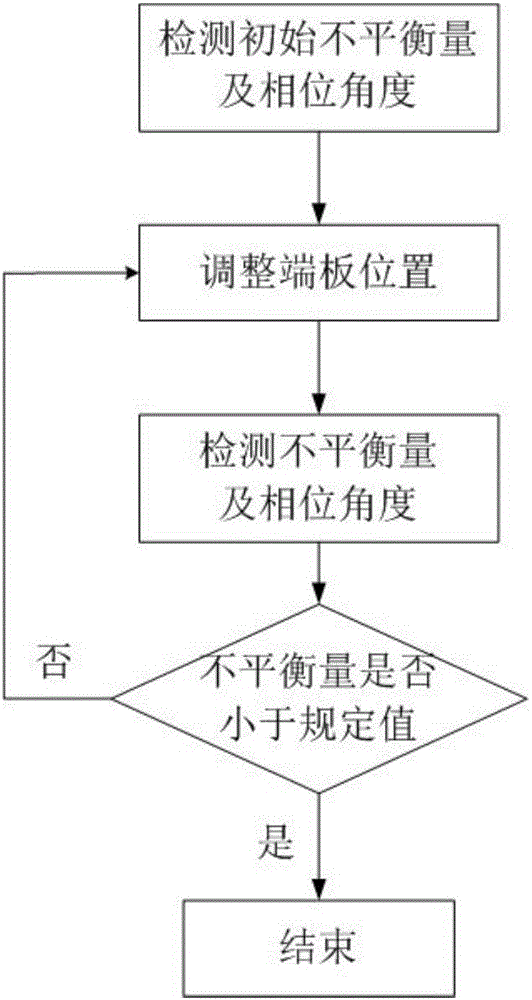

[0025] The concrete implementation method of the present invention is as follows:

[0026] The existing motor dynamic balance adjustment generally uses a number of round holes on the motor end plate to add lead or copper blocks when using the weight method to adjust the unbalanced amount, and solidify it with balance cement. Although this can also realize the dynamic balance of the motor rotor. Balanced, but due to the limited number of round holes, it is impossible to completely cover the surface of the end plate, which leads to unbalanced phase angles during dynamic balance adjustment. Weighting approximates the dynamic balance, and there is another disadvantage of achieving dynamic balance through the weighting method, that is, due to the high centrifugal force when the high-speed motor is working, the balance weight added through the weighting method may fall off under the action of centrifugal force.

[0027] In order to solve the above problems, the present invention pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com