Hot rolling method of high carbon steel

A high-carbon, finish-rolling technology, used in metal rolling, metal rolling, workpiece heating devices, etc., can solve the problems of difficulty in taking into account quality and passability, and cannot increase the heating temperature of high-carbon steel, and achieve stable manufacturing. , the effect of inhibiting high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

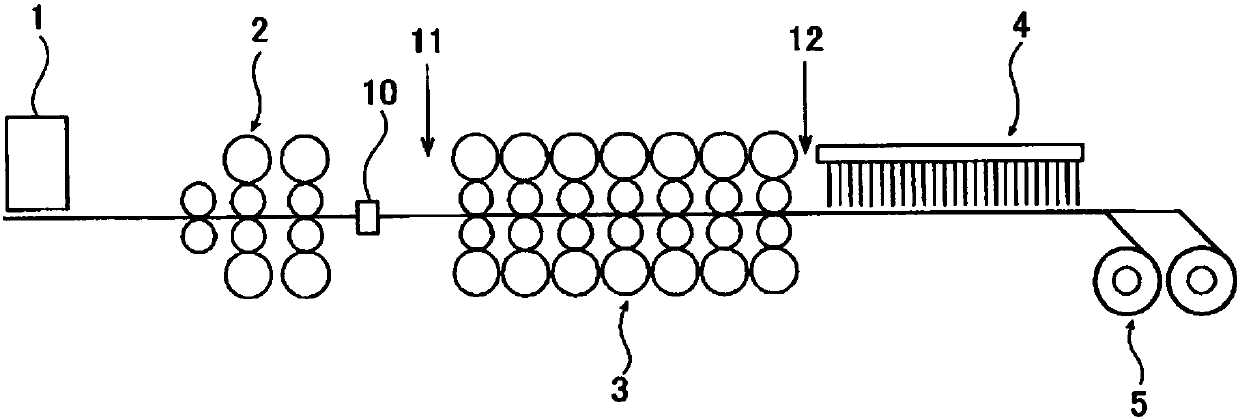

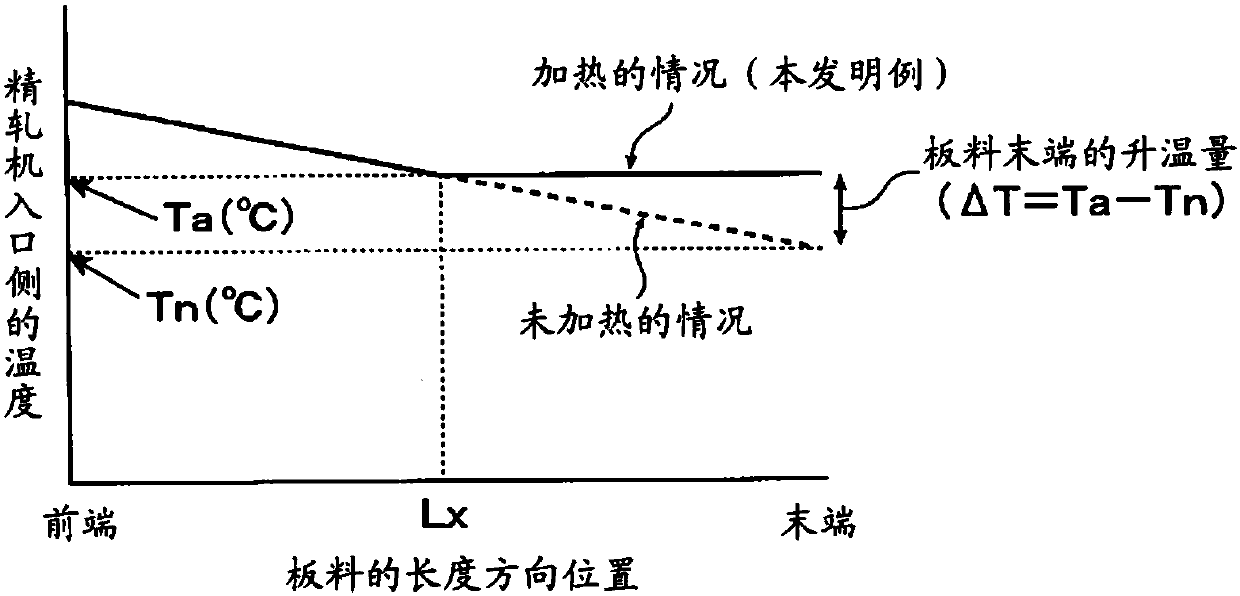

[0044] Using a slab of high-carbon steel (S45C specified in JISG4051) having the component composition (mass%) of steel symbol A shown in Table 1, in figure 1 Hot rolling is performed on the hot rolling line shown. The thickness of the steel slab used was 260 mm and the width was 1150 mm. After the steel slab was heated in a heating furnace to the extraction temperature of the heating furnace shown in Table 2, the width was finished to 1065 mm with a finishing press not shown in the figure. Carry out rough rolling, make the plate material of thickness 40mm, width 1065mm. In the example of the present invention (rolling number 1), the obtained sheet was finished-rolled by setting the upper limit of the temperature increase amount at the end of the sheet to 40° C. with a plate heater. In addition, as a comparison, for the case of heating with a plate heater with a temperature increase exceeding the above-mentioned upper limit (rolling number 2), the case of heating the extracti...

Embodiment 2

[0054] Based on the results of Example 1 above, the upper limit of the amount of temperature increase at the edge of the sheet was set to 40°C. For the six billets 6 of steel code A, heating was carried out under the same conditions as in Example 1 above, except that the upper limit of the temperature increase at the end of the sheet was changed to 40°C (repeated implementation) and 35°C. Rolling (rolling number 4~9). The results are shown in Table 3.

[0055] As a result, in either case, hot rolling can be performed without causing cracks in the steel sheet in the cooling zone, and red scale can be produced, and high-quality steel sheets can be produced. From the above, it can be seen that by predetermining the upper limit of the amount of temperature increase at the end of the sheet metal, it is possible to stably manufacture high-quality high-carbon steel sheets without causing quality problems such as red scale formation.

[0056] [table 3]

[0057]

Embodiment 3

[0059] Using slabs of high-carbon steel (S45C specified in JISG4051) with the composition (mass %) of steel symbols B to E shown in Table 4, the upper limit of the temperature rise at the end of the sheet was set to 50°C, Hot rolling was performed under the same conditions as in Example 1 above except that 40°C and 35°C. Table 5 shows the results of hot rolling.

[0060] In the examples of the present invention (rolling numbers 10 to 14) in which the upper limit of the temperature rise at the end of the sheet was set at 40°C and 35°C, hot rolling could be performed without causing cracks in the steel sheet in the cooling zone, and there was no red oxidation. The production of skin enables the manufacture of high-quality steel plates. On the other hand, in the comparative example (rolling number 15) in which the amount of temperature rise was too high and exceeded the range of the present invention, cracks occurred in the steel sheet in the cooling region.

[0061] [Table 4] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com