A Comprehensive Utilization Process of Microwave Expanded Tobacco Stem

A technology for expanding and expanding tobacco stems by microwave is applied in the field of tobacco processing, which can solve the problems of heavy charred smell and large breaking, and achieve the effects of less loss of natural tobacco aroma, reduced carbonization and uniform expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

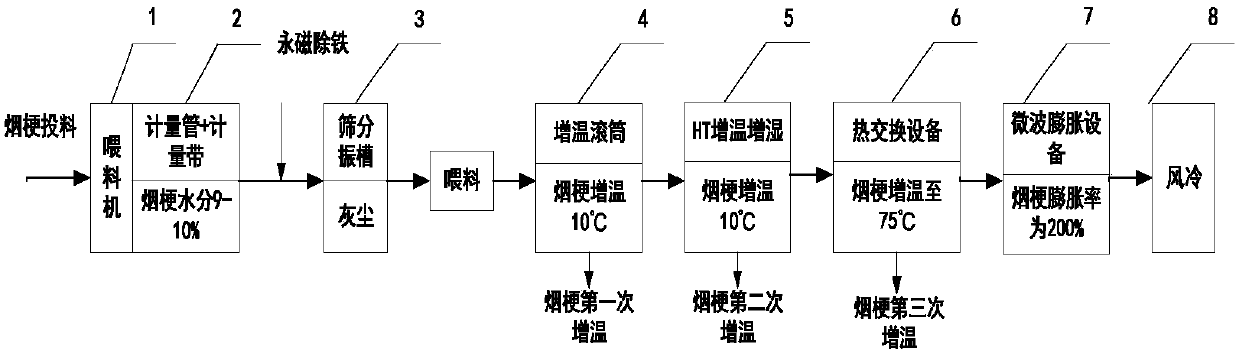

[0027] (1) The tobacco stem expands step by step (such as figure 1 shown): after the tobacco stem passes through the feeding device 1 and the flow metering device 2, it is fed to the screening and vibrating tank device 3, and after dust and impurities are removed, it is put into the drum heating device 4 for the first heating of the tobacco stem At about 15°C, the temperature of the tobacco stems is 35°C, and then the tobacco stems enter the heating and humidifying equipment (HT) 5 for the second heating of the tobacco stems, and the temperature is 140°C, and the tobacco stems are pretreated for 10 minutes. Increase the temperature by about 15°C. After the second heating of the tobacco stems, the temperature of the tobacco stems is about 50°C, and the moisture content is controlled at about 13%. The exchanged tobacco stems are released from high pressure to normal pressure to obtain pre-expansion and third temperature increase. The temperature of the pre-treated tobacco stems ...

Embodiment 2

[0032] (1) The tobacco stem expands step by step (such as figure 1 shown): after the tobacco stem passes through the feeding device 1 and the flow metering device 2, it is fed to the screening and vibrating tank device 3, and after dust and impurities are removed, it is put into the drum heating device 4 for the first heating of the tobacco stem At about 10°C, the temperature of the tobacco stems is 30°C, and then the tobacco stems enter the heating and humidifying equipment (HT) 5 for the second heating of the tobacco stems, and the temperature is 120°C, and the tobacco stems are pretreated for 30 minutes. The temperature is increased by about 10°C. After the tobacco stems are heated twice, the temperature of the tobacco stems is 40°C, and the moisture content is controlled to about 14%. Then it enters the heat exchange equipment 6 filled with saturated steam, and is heated by saturated steam so that the heat exchanged The tobacco stems are released from high pressure to norm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com