Method for expanding tobacco stems grade by grade

A technology of tobacco stems and tobacco stems, which is applied in the field of step-by-step expansion of tobacco stems, can solve the problems of weak processing strength, low processing cost, and high production cost, and achieve enhanced liquid absorption capacity, less loss of natural tobacco flavor, and crushing The effect of phenomenon reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

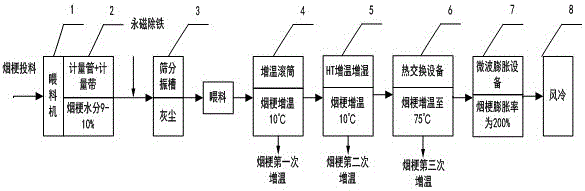

[0015] Tobacco stem step-by-step expansion process (such as figure 1 shown): after the tobacco stem passes through the feeding device 1 and the flow metering device 2, it is fed to the screening and vibrating tank device 3, and after dust and impurities are removed, it is put into the drum heating device 4 for the first heating of the tobacco stem At about 10°C, the temperature of the tobacco stems is 30°C, and then the tobacco stems enter the heating and humidifying equipment (HT) 5 for the second heating of the tobacco stems, and the tobacco stems are pretreated at a temperature of 120°C for 30 minutes, and the tobacco stems increase in temperature. The temperature is about 10°C. After the tobacco stems are heated twice, the temperature of the tobacco stems is 40°C, and the moisture content is controlled at about 12%. Then it enters the heat exchange equipment 6 filled with saturated steam, and is pretreated by saturated steam heating or steam solid medium. , so that the hea...

Embodiment 2

[0017] Tobacco stem step-by-step expansion process (such as figure 1 shown): after the tobacco stem passes through the feeding device 1 and the flow metering device 2, it is fed to the screening and vibrating tank device 3, and after dust and impurities are removed, it is put into the drum heating device 4 for the first heating of the tobacco stem At about 15°C, the temperature of the tobacco stems is 35°C, and then the tobacco stems enter the heating and humidifying equipment (HT) 5 for the second heating of the tobacco stems, and the tobacco stems are pretreated at a temperature of 140°C for 20 minutes, and the tobacco stems increase in temperature. After the tobacco stems are heated twice, the temperature of the tobacco stems is about 50°C, and the moisture content is controlled at about 13%. After that, it enters the heat exchange equipment 6 filled with saturated steam, and is heated by saturated steam or preheated by steam solid medium. Treatment, so that the heat-exchan...

Embodiment 3

[0019] After the tobacco stem passes through the feeding device 1 and the flow metering device 2, it is fed to the screening and vibrating tank device 3, after dust and impurities are removed, it is placed in the drum heating device 4 for the first heating of the tobacco stem at about 20°C. The temperature of the tobacco stems is 40°C, and then the tobacco stems enter the heating and humidification device (HT) 5 for the second heating of the tobacco stems, and the tobacco stems are pretreated at a temperature of 160°C for 10 minutes, and the temperature of the tobacco stems is increased by about 20°C , after the tobacco stems are heated twice, the temperature of the tobacco stems is about 60°C, and the moisture content is controlled at about 14%; then it enters the heat exchange equipment 6 filled with saturated steam, and is heated by saturated steam or pretreated by steam solid media, so that after The heat-exchanged tobacco stems are released from high pressure to normal pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com