Bamboo pole heating, softening and bending device

A bending device and bamboo branch technology, which is applied in the field of bamboo branch heating and softening bending device, can solve the problems of different degrees of softening of bamboo branches, cracking of bamboo branches, uneven heating of bamboo branches, etc., so as to reduce carbonization, avoid overheating, and have good appearance quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

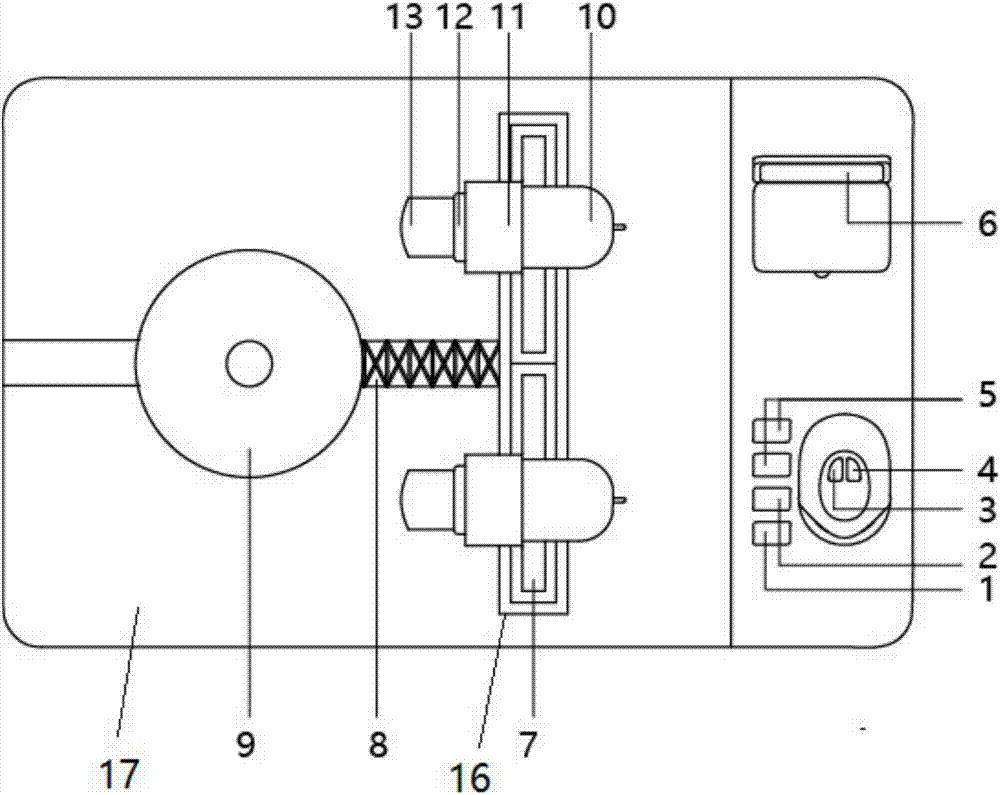

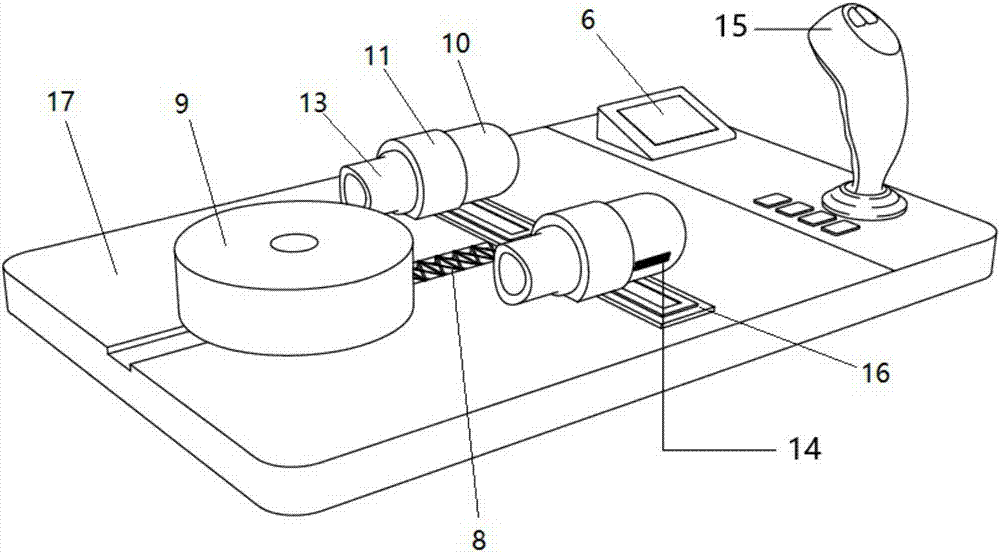

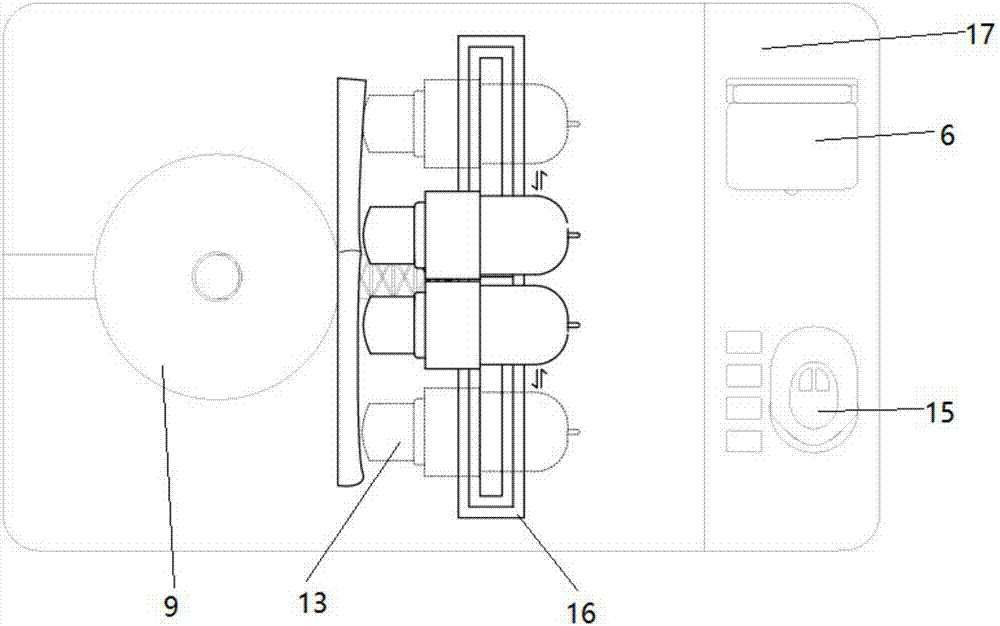

[0042] The embodiment of the present invention discloses a bamboo branch heating, softening and bending device. Several heating machines are movably arranged in the first guide rail 16 through a first moving assembly 7, and a control module controls the heating machines in the first guide rail 16. The guide rail 16 moves back and forth to uniformly heat the bamboo branches placed in front of several heating machines, which realizes the uniform heating and softening of the bamboo branches, and solves the problem that the existing methods of bending the bamboo branches easily cause the bamboo branches to be unevenly heated and burnt , Burns or even catches fire, which causes the bamboo branches to soften to different degrees, and the bamboo branches break when they are bent.

[0043] See Figure 1 to Figure 5 , An embodiment of a bamboo branch heating, softening and bending device provided in the embodiment of the present invention includes: a worktable, a first guide rail 16 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com