Temperature control type centrifugal lead powder machine structure

A centrifugal lead, temperature-type technology, applied in the field of temperature-controlled centrifugal lead powder machine structure, can solve the problems of production efficiency to be improved, drum temperature rise, etc., to avoid continuous temperature rise, inhibit excessive oxidation, and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

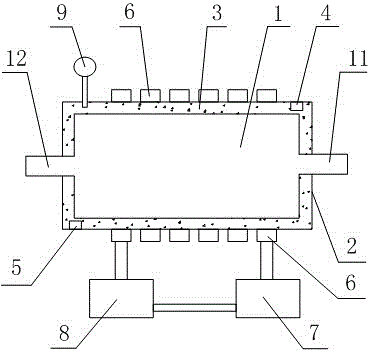

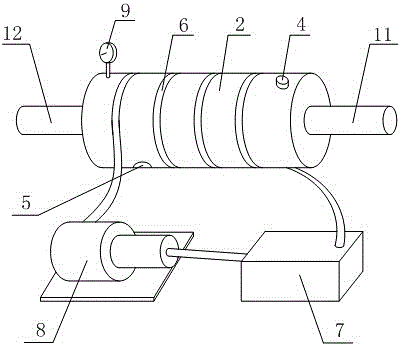

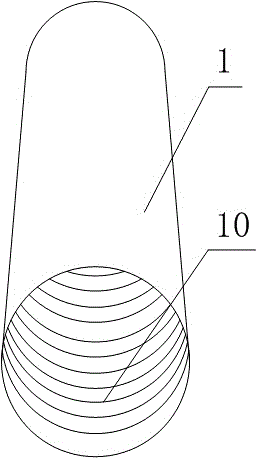

[0023] Such as Figure 1 to Figure 4The structure of the temperature-controlled centrifugal lead powder machine shown includes a drum 1 provided with a feed inlet 11 and a powder outlet 12. The drum 1 is a cylindrical structure, and the drum 1 rotates around the axis of the cylinder. The inner wall of the drum 1 is evenly distributed. A plurality of annular protrusions 10, the annular protrusions 10 are parallel to the circular section of the drum 1; the drum 1 is arranged in a fixed housing 2, and there is a gap 3 between the housing 2 and the drum 1, the gap 3 is filled with heat-conducting silicone grease, the upper part of the housing 2 is provided with a grease injection hole 4, and the lower part of the housing 2 is provided with a grease discharge hole 5; the surface of the housing 2 is wound with a cooling water pipe 6, and one end of the cooling water pipe 6 is connected to The other end of the water chiller 7 is connected to the water pump 8, and the water outlet end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com