A drilling method for large-size circuit boards

A technology of large-size circuit boards and processing methods, applied in the field of circuit boards, can solve problems such as inability to process large-size boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in combination with specific embodiments.

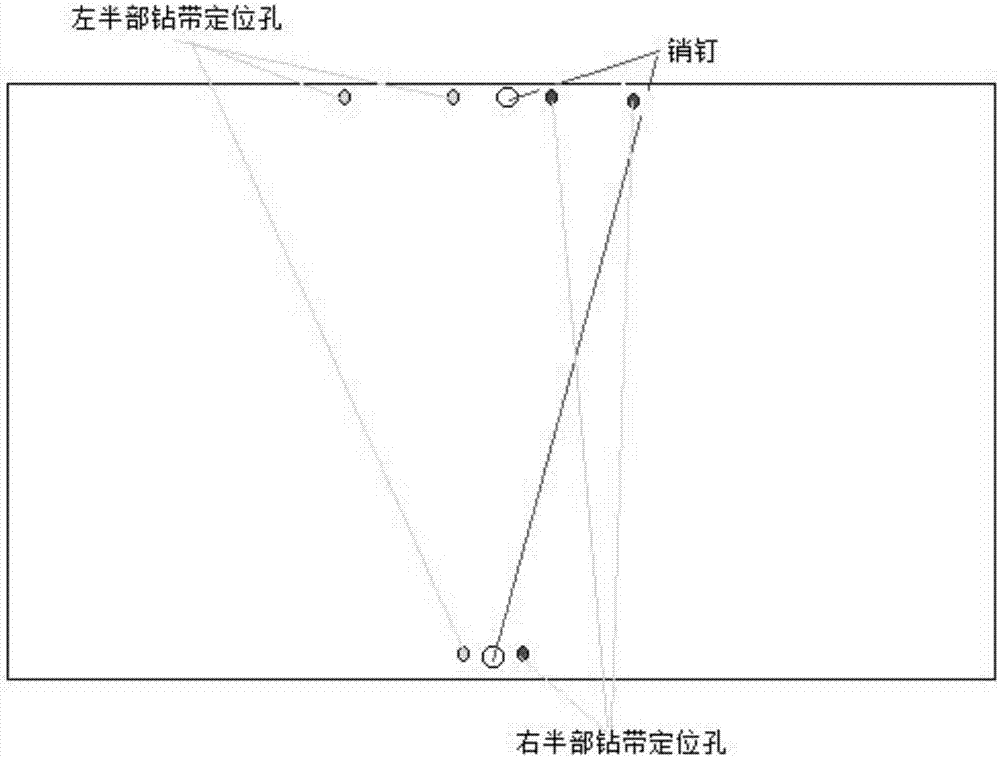

[0025] Segmented positioning cross-axis operation, in the engineering design, first design three point holes within 10.5" on the left and right sides of the middle, divide the main drilling program into two programs according to the centerline position, and use the first drilled holes respectively The positioning hole is positioned and drilled twice.

[0026] A method for drilling a large-sized circuit board, the steps of the method are as follows:

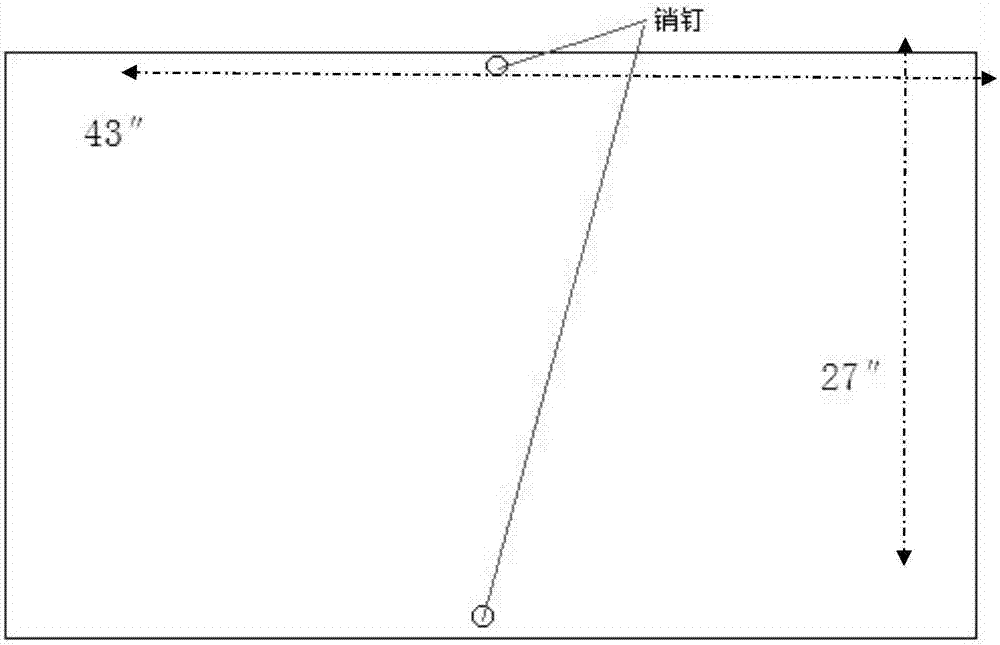

[0027] a. Pinning: Place the circuit board in the pin machine, use the pin machine to punch the pin for positioning in the middle of the long side of the circuit board;

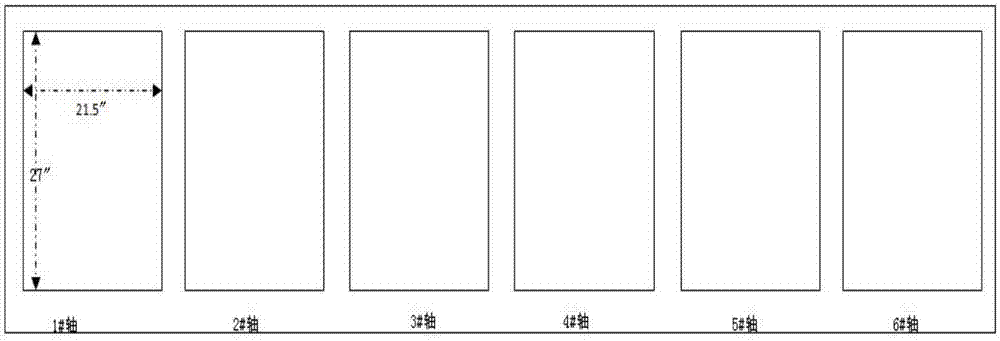

[0028] b. Set the board: place the circuit board with the pins in step a on the shaft table of the drilling machine. The drilling machine includes six drilling shafts, and the drilling shafts are the first drilling shaft, the second drilling shaft, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com