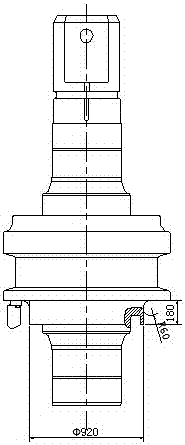

A 1450 hot strip rolling mill combination vertical roll

A technology of vertical rolls and roll sleeves, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of blank lengthening, large gross-to-net ratio, waste, etc., and achieve the effect of reducing turning processing and improving roll life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

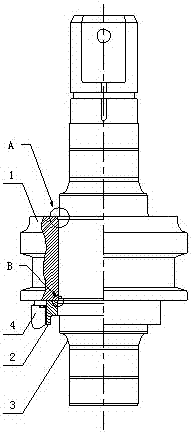

[0016] Below in conjunction with assembly embodiment the present invention is described in further detail:

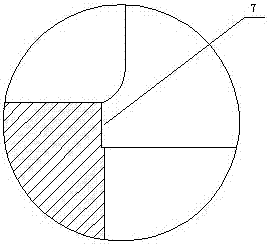

[0017] Such as Figure 2-4 As shown, the combined vertical roller of the present invention includes three parts: a roller shaft 3, a main body roller sleeve 1, and a waterproof ring 2, wherein the roller shaft is made of forged steel; the outer layer of the main body roller sleeve is a high-hardness alloy, and the inner layer is ordinary cast steel, The waterproof ring is made of forged steel, the main roller sleeve 1 is set on the roller shaft 3, the main roller sleeve 1 and the roller shaft 3 adopt an interference fit, and are axially positioned by the main thrust table 5 and the anti-channeling table 7 to achieve axial Fixed and radially tight; the waterproof ring 2 is set under the main roller sleeve 1 on the roller shaft 3, and the upper end surface of the waterproof ring 2 is close to the lower end surface of the main roller sleeve 1. The waterproof ring 2 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com