Manufacturing method of rotary unit in rudder propeller

A production method and a technology of rotating flanges, which are applied in the manufacture of tools, steering and steering with propulsion components, arc welding equipment, etc., can solve the problems of high cost and cycle of electroplating process, and cannot use red sleeve process, etc., so as to ensure the coating effect , Realize the effect of being simple and convenient and meeting the design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

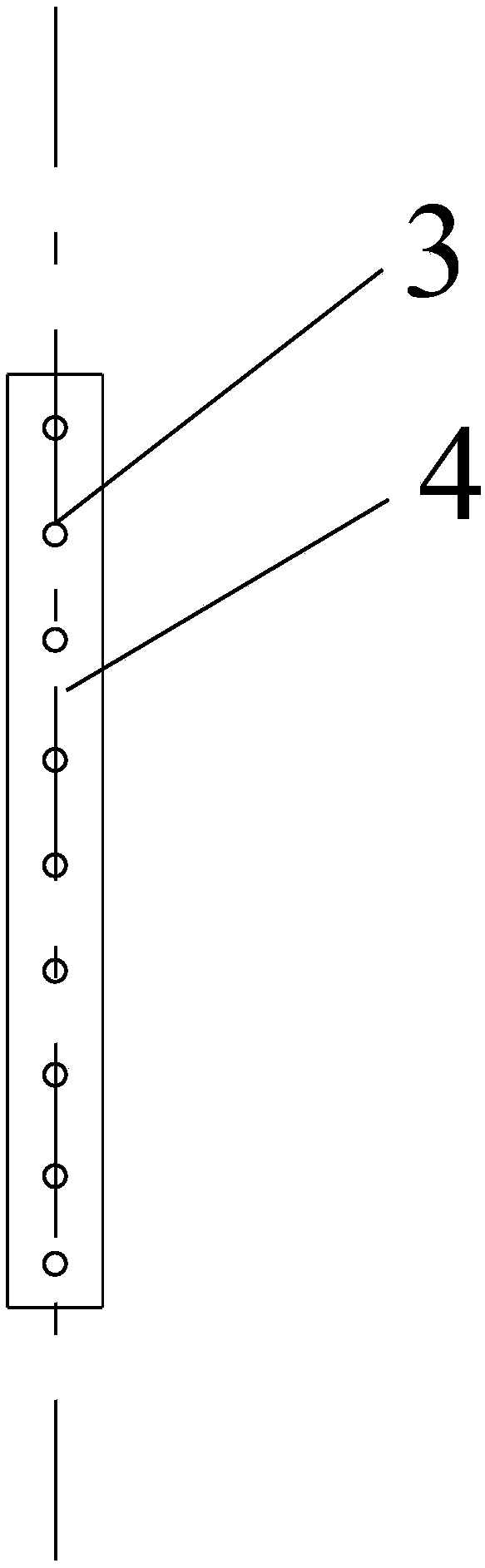

[0054] The embodiment of the present invention provides a manufacturing method of the rotary unit in the rudder oar, which can be applied to the telescopic full-rotation rudder oar device, and is especially suitable for the manufacture of the rotary unit in the rudder oar of the 300-lift pipe-laying ship.

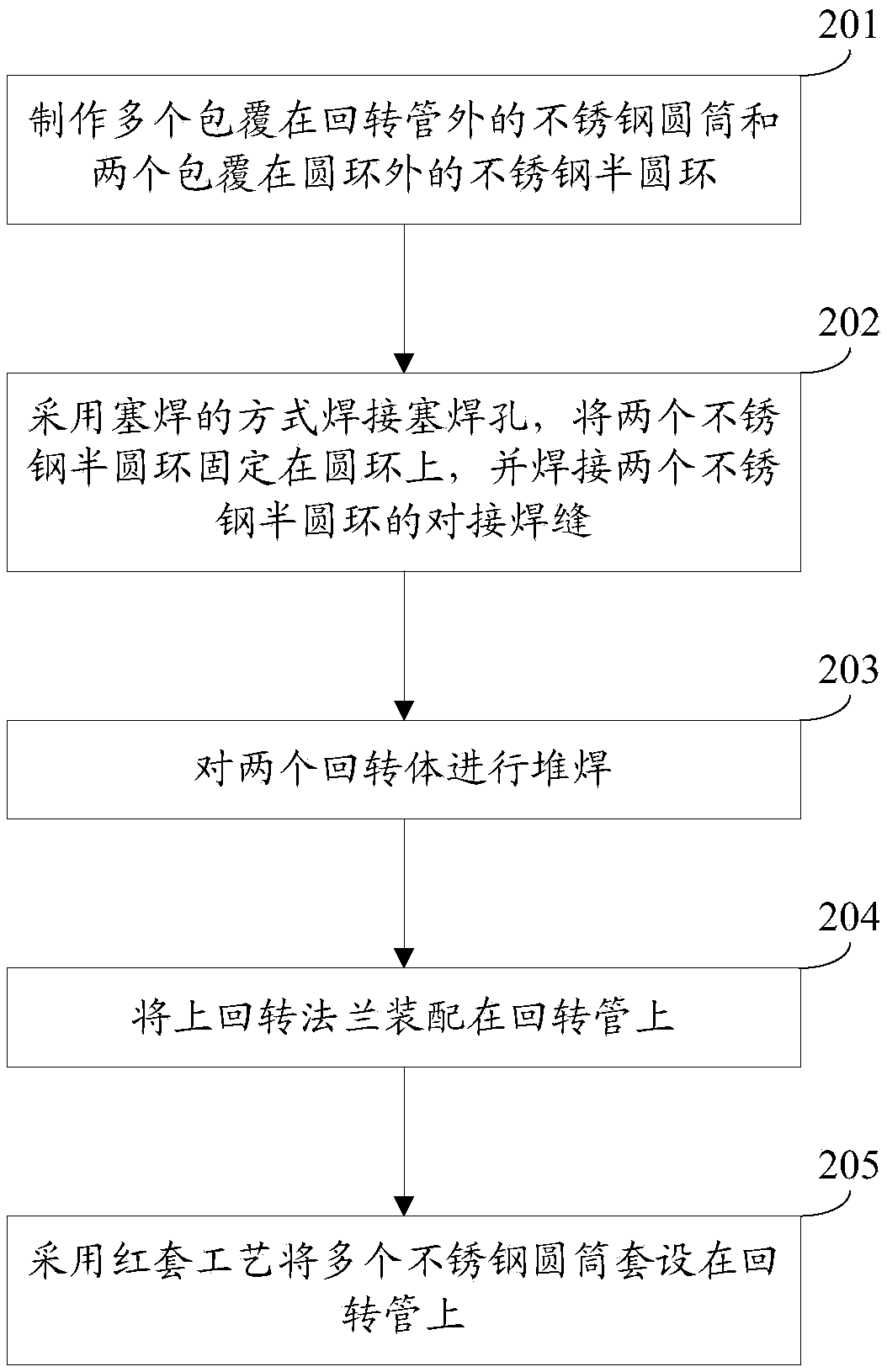

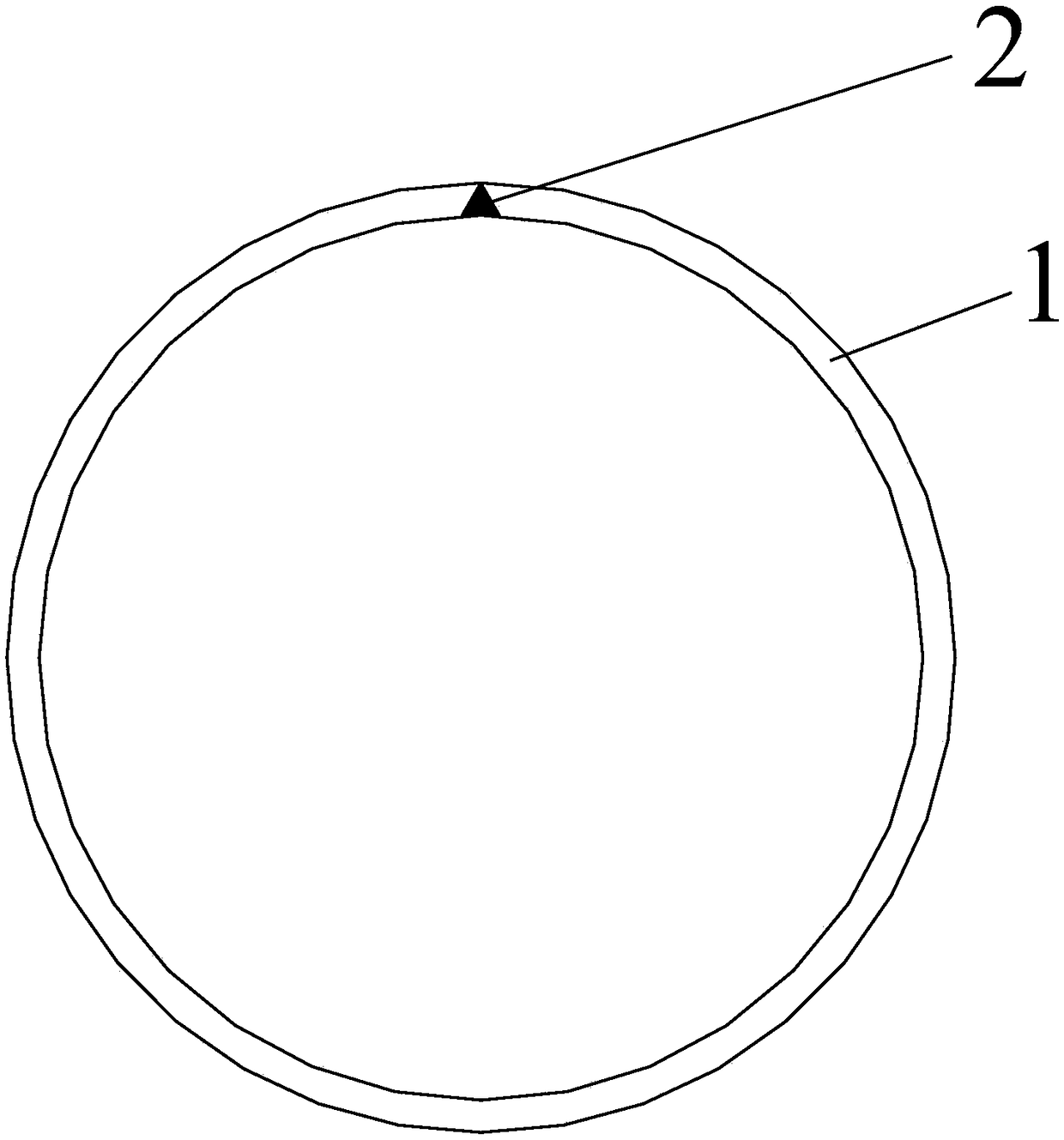

[0055]Specifically, the rudder oar includes a propulsion unit and a rotary unit. The propulsion unit includes an input shaft, a transmission shaft, a propeller shaft, an upper bevel gearbox with an upper bevel gear inside, a lower bevel gearbox with a lower bevel gear inside, the input shaft and the transmission shaft are driven through the upper bevel gear, and the transmission shaft It is engaged with the propeller shaft through the lower bevel gear. The slewing unit includes a slewing motor, a slewing bearing, an upper slewing flange, a slewing tube, and a lower slewing flange. The slewing motor and slewing bearing are arranged on the upper bevel gearbox. The flange and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com