Dust-free metal cutting and grinding equipment

A processing equipment, cutting and grinding technology, applied in the direction of metal processing equipment, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve the problem of metal shavings and dust not taken well, and achieve the effect of convenient centralized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

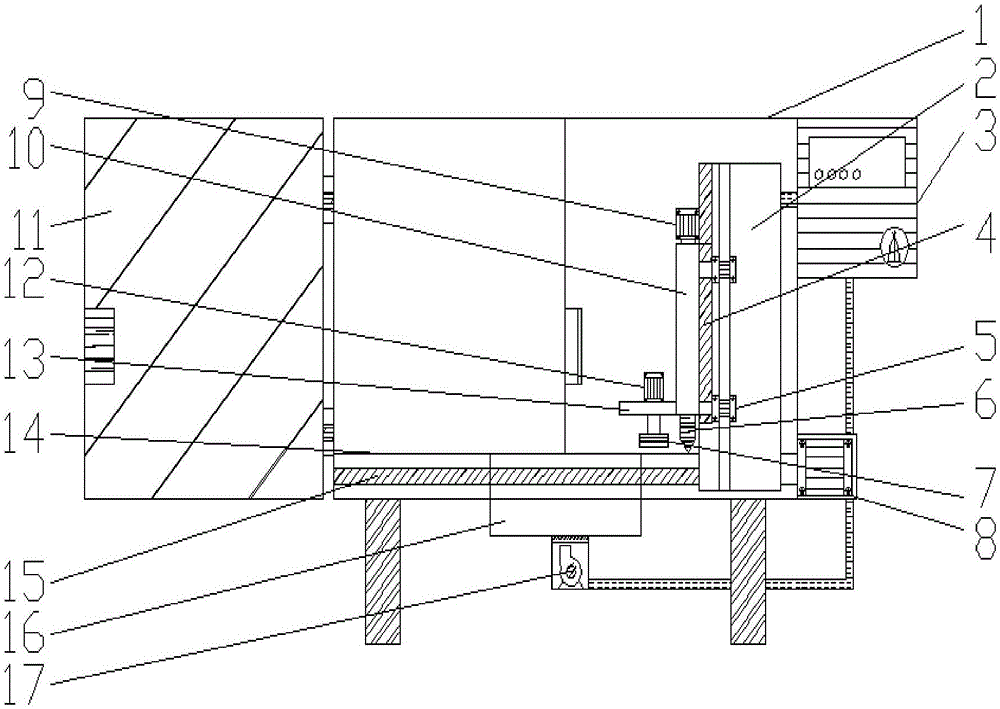

[0014] See figure 1 , The dust-free metal cutting and grinding processing equipment of the present invention includes a glass cover 1, a cutter mounting bracket 2, an electrical control box 3, a vertical slide rail 4, a vertical feed servo motor 5, a cutting head 6, a grinding knife Head 7, infeed servo motor 8, cutting motor 9, glass cover door 11 and grinding motor 12. in,

[0015] In this embodiment, a working table 14 is arranged inside the glass cover 1, a horizontal slide rail 15 is installed under the cutter mounting bracket 2, a cutter mounting bracket 2 is connected to the left side of the electrical control box 3, and a vertical slide rail 4 is connected to the left side. A cutting rod 10 is installed, a vertical slide rail 4 is connected to the left side of the vertical feed servo motor 5, a wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com