A clamping device for thin plate workpieces with holes

A workpiece clamping and clamping device technology, which is applied in the field of thin plate workpiece clamping devices with holes, can solve the problems of unfavorable workpiece quality control, large workpiece processing dispersion, and difficulty in ensuring flatness, etc., and achieves high processing efficiency. The effect of reducing deformation and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

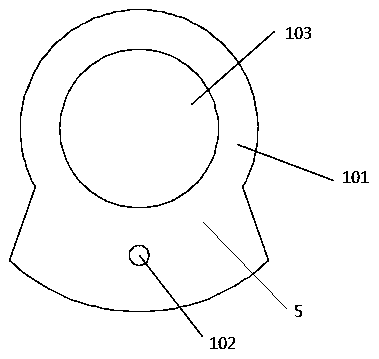

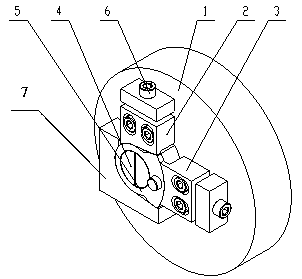

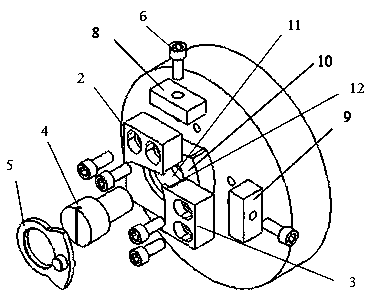

[0022] The clamping device for thin plate workpieces with holes in embodiment 1 is used for clamping the cam plate for load switch. In other embodiments, the clamping device can also be used for clamping other thin-plate workpieces with holes.

[0023] The supporting structure of the inner hole of the clamping device for thin plate workpieces with holes in Example 1 is an expanding mandrel, which is used for positioning the middle hole of the workpiece and preventing deformation of the middle hole. In other embodiments, the inner hole support structure can also be other structures that prevent the deformation of the middle hole of the workpiece, such as a cylindrical support block that is installed in the middle hole of the workpiece to support the middle hole of the same size as the middle hole of the workpiece.

[0024] The clamping device for thin plate workpieces with holes in embodiment 1 realizes the clamping of workpieces by fixing the groove wall of the platform groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com