Multi-driven three-degree-of-freedom leaf spring type micro-nano operating platform and method

A technology of operating platform and degrees of freedom, which is applied to parts of instruments, program-controlled manipulators, instruments, etc., can solve problems such as the inability to realize the Z-axis rotation degree of freedom, the inability to realize the Z-axis rotation degree of freedom, and the difficulty in realizing large-span travel, etc. Achieve the effect of widening the scope of use, overcoming the transmission error, and improving the guiding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

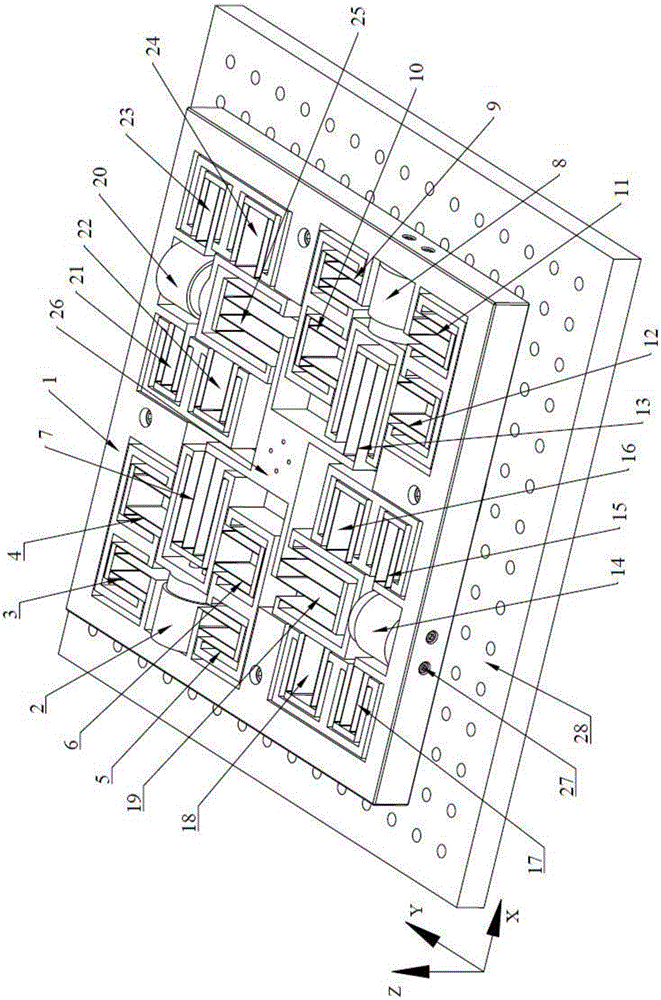

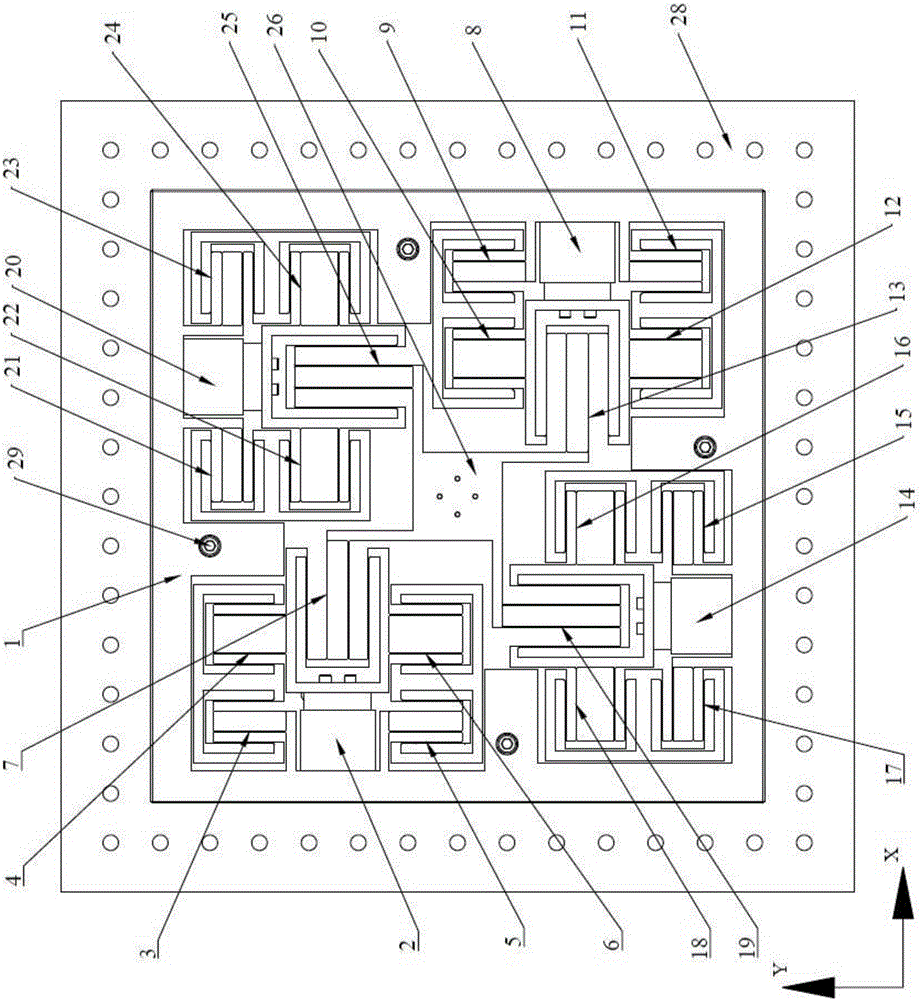

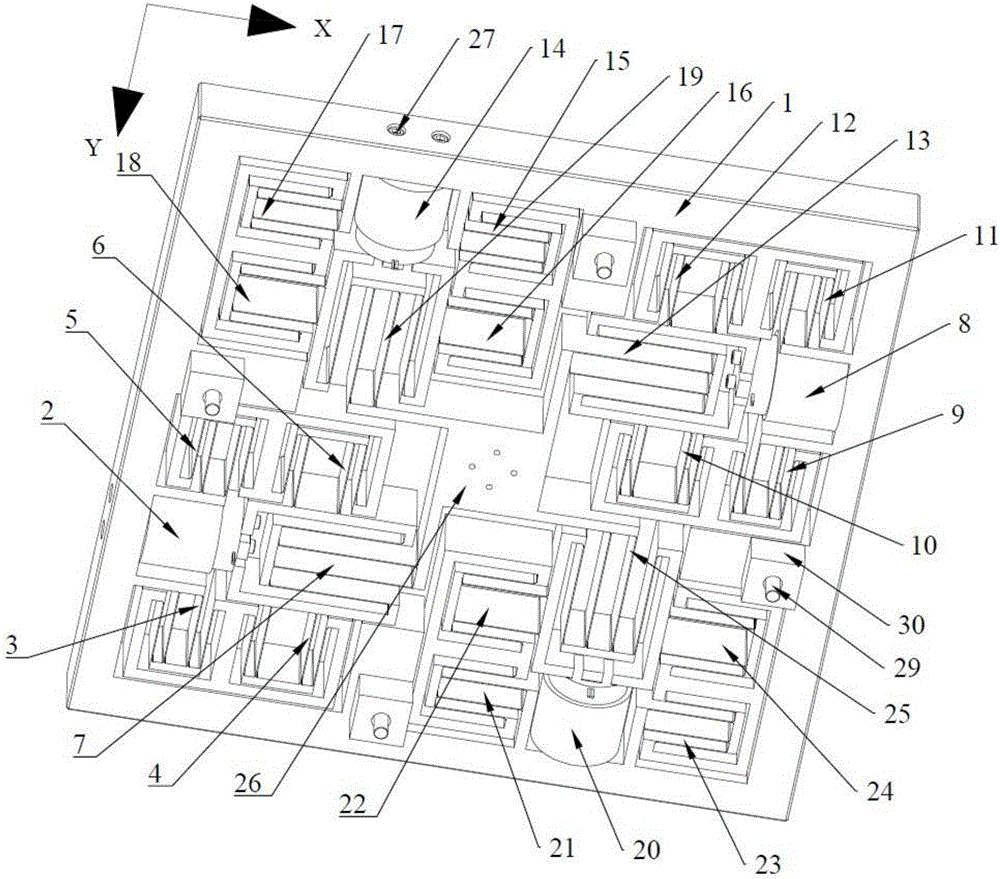

[0040] like figure 1 , figure 2As shown, a multi-drive three-degree-of-freedom leaf spring micro-nano operating platform adopts a four-drive method in this embodiment. The platform structure includes: a fixed platform 1, and the fixed platform 1 is processed by wire cutting of integrated materials , four driving mechanisms with the same structure are evenly distributed around the circumference of the fixed platform 1. The center of the fixed platform 1 is provided with a mobile platform 26. The part of the first driving mechanism that removes the driving power source is the first leaf spring unit, and the first leaf spring The unit consists of a first leaf spring (auxiliary leaf spring) 3, a second leaf spring (auxiliary leaf spring) 4, a third leaf spring (auxiliary leaf spring) 5, a fourth leaf spring (auxiliary leaf spring) 6 and a first guide plate Spring 7, the first leaf spring 3, the second leaf spring 4, the third leaf spring 5, the fourth leaf spring 6 and the first...

Embodiment 2

[0045] like Figure 7 As shown, the flexible auxiliary leaf spring is connected in parallel and symmetrically arranged at the output end of the driving power source. This structural design can effectively increase the stiffness and improve the bandwidth of the entire micro-nano platform, which is suitable for high-bandwidth and small-travel occasions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com